HEV/EV Traction Inverter Design Guide Using Isolated

Apr 1, 2023 · Zooming in to the traction inverter system reveals multiple blocks including the power management IC (PMIC) and the microcontroller (MCU), the high-power IGBT or SiC

High Voltage Inverter: Unlocking the Potential of High

Aug 17, 2025 · Due to its ability to handle high voltages, its use allows the operation of devices with large loads while ensuring precise control and optimal energy efficiency. This article will

A technical review of modern traction inverter systems used

Nov 1, 2023 · These structures'' key characteristics, which make them ideal for the upcoming generation of traction inverters, include low-output current distortion, dv / dt reduction,

A review on topology and control strategies of high-power inverters

Feb 15, 2025 · In large-scale applications such as PV power plants, "high-power" in medium voltage (MV) inverters is characterized by the use of multilevel inverters to enhance efficiency

HEV/EV Traction Inverter Design Guide Using Isolated

Apr 1, 2023 · Texas Instruments'' UCC217xx-Q1 family of reinforced isolated gate drivers have integrated protection and monitoring features that simplify the design of high-power traction

High Performance Power Hardware-in-the-Loop Testing of

Oct 25, 2022 · An innovative approach, which can accelerate the development and testing process of traction inverters and their control systems at different operating conditio

Next Generation Traction Inverter

Dec 19, 2023 · It continues monitoring the high voltage supply and motor speed, and uses those measurements and the current fault signature to maintain a safe operational state. This is a

Application Analysis of High

Aug 18, 2025 · 2 Application Example of High-Voltage Inverters in Power Plants A power plant''s power system typically includes equipment from turbine generators, boilers, water treatment,

High Voltage 800V SiC Inverter | Valeo for

Sep 2, 2024 · What is a High Voltage Inverter? The inverter is the brain at the heart of the powertrain, it controls the electric motor. It converts Direct Current

The Role of High Input Voltage Inverters in Modern Energy

Feb 25, 2024 · Moreover, advancements in technology have led to enhanced features and monitoring capabilities, making high input voltage inverters an indispensable tool for optimizing

EV Traction Motor Power Inverter Control Reference

Aug 25, 2022 · 2 General Description The NXP EV Power Inverter Control Reference Platform provides a hardware reference design, system basic software, and a complete system

Ultra-Low Power and High-Speed Design Analysis of 1-Bit

4 days ago · Ultra-Low Power and High-Speed Design Analysis of 1-Bit 20T-HyDGFA using a Dual-Gate Domino Inverter | Analog Integrated Circuits and Signal Processing

Analysis of the Working Principle and Application of High Voltage Inverter

May 15, 2024 · The working principle of high voltage inverter is to control the speed of motor by changing the frequency of alternating current (AC), MICNO high voltage inverter adopts

High Voltage Seminar

Jun 26, 2023 · Micro inverter can be found as current source inverter (CSI) or voltage source inverter (VSI) • AC/DC converter: – When used with a DC/DC controller as a current source

6 FAQs about [Processing high voltage inverter]

What is a high-power MV inverter?

In large-scale applications such as PV power plants, "high-power" in medium voltage (MV) inverters is characterized by the use of multilevel inverters to enhance efficiency and scalability. These high-power MV systems generally function within a power range of 0.4 MW–40 MW, and in certain applications, can reach up to 100 MW.

What is a high power switch in an inverter?

The high-power switches are the most critical component in the inverter as they control the flow of current to the motor to generate motion. As such, the switches' are monitored and protected by sensing their temperature, voltage and current throughout their operation.

How to achieve high output power levels in ChB-based inverters?

In order to attain elevated output power levels, obviate the necessity for low-frequency transformers, generate multilevel output voltage, and implement distributed MPPT, a novel three-phase topology has been introduced in Ref. tailored for CHB-based inverters.

What are the applications of control systems in high-power inverters?

One of the application of control systems in high-power inverters is to increase the speed and accuracy in achieving MPPT. Control algorithms continuously examine the input of the inverter and adjust its operational parameters to extract the maximum available power . Another essential factor is computational complexity.

What is a high power inverter with a NPC topology?

The high-power inverter with a NPC topology, also known as a three-level inverter, is a type of multilevel converter. In contrast to traditional two-level inverters, which have two voltage levels (positive and negative), this inverter has an additional intermediate voltage level known as the neutral point .

Are high-power ChB inverters able to control output power?

One of the inherent issues in high-power CHB inverters is the imbalance in the output power, leading to instability and reduced current in grid-connected systems. Therefore, an adaptive control technique has been proposed to regulate the output power in these converters.

Update Information

- Inverter outputs high current and high voltage

- Can a high voltage inverter be charged for a long time

- Can the inverter convert high voltage into low voltage

- Does the inverter have high voltage and high current

- Construction site low voltage to high voltage inverter

- High voltage grid-connected inverter communication method

- High voltage and low current inverter

- High voltage power inverter

- High Voltage DC Step-Down Inverter

- Household high voltage off-grid inverter

- 100kv ultra high voltage inverter price

- EK High Voltage Inverter

- Can t the high voltage of the inverter be adjusted to a lower voltage

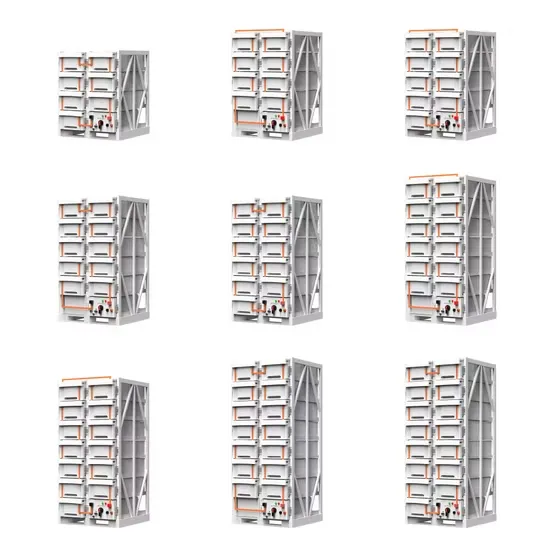

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.