Wattage vs Voltage vs Current on Inverter Ratings

Jul 6, 2024 · Should I be using Max power voltage and max power current when comparing wattage of system to wattage of inverter PV input? I''m trying to max out my PV wattage input

Power Frequency Inverter vs. High Frequency

May 15, 2024 · In the field of power electronics and energy conversion, inverters, as key equipment for power conversion, play a vital role. Inverters are capable

Inverters, Types and Voltages

Dec 31, 2024 · Choose high voltage inverters if efficiency, scalability, or long-distance transmission is a priority. Use low-frequency inverters for systems with high surge demands or

Comparison and Analysis of High Voltage Inverter and Low Voltage

Jul 28, 2022 · For testing high-voltage, large-capacity high-voltage inverters, due to the large voltage and current values, general instruments cannot meet the requirements. Voltage or

An advanced guide to Understanding DC to AC inverters

Apr 4, 2024 · The major disadvantage of direct current is the commutation problem which means it''s hard to produce electric power at high DC voltage. Doing so will require extra equipment,

Inverter AC Starting Current: A Comprehensive Guide

Importance of Starting Current Why does starting current matter? Well, a high starting current can cause a strain on your electrical system, leading to potential damage or tripped breakers. Plus,

High Voltage Inverter: Unlocking the Potential of High

Aug 17, 2025 · Generally, a high voltage inverter is a type of inverter voltage that works by converting direct current (DC) into alternating current (AC) at high voltage. This high-voltage

Power Inverters: What Are They & How Do They

Dec 17, 2019 · Key learnings: Inverter Definition: An inverter is defined as a power electronics device that converts DC voltage into AC voltage, crucial for

The Difference Between High Voltage Converters and Inverters

Dec 4, 2024 · Key Differences Between Converters and Inverters While both converters and inverters are integral to energy transformation, they serve distinct purposes. Converters

High-voltage VS Low-voltage Inverters: What''s the difference?

May 14, 2025 · High-voltage inverters are designed to work with DC voltages typically ranging from 150V to 600V or even more. They are common in larger residential or commercial solar

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · The inverter outputs a pulsed voltage, and the pulses are smoothed by the motor coil so that a sine wave current flows to the motor to control the speed and torque of the

High Voltage Inverters: Understanding Its Benefits and

Jan 23, 2025 · High-voltage inverters play a crucial role in converting DC (direct current) into AC (alternating current) at higher voltage levels, making them ideal for various applications such

6 FAQs about [Does the inverter have high voltage and high current ]

Is there a difference between a commercial inverter and a high voltage?

For 'reasonable' voltages, in the several 10s to several 100s range, there's not a lot of difference between the efficiency of commercial inverters. Comparably higher voltage is more preferable when given choice between different voltages.

What is the difference between high voltage and low voltage inverters?

A high voltage array can use smaller cross-section cables to connect it to the inverter, or can be sited further from the inverter, than a low voltage array. For 'reasonable' voltages, in the several 10s to several 100s range, there's not a lot of difference between the efficiency of commercial inverters.

Why is my solar inverter voltage too high?

* VAC HIGH - The solar inverter is measuring a grid (mains) voltage that is too high in relation to the parameters that the solar inverter has been set to safely operate within. If this fault persists contact us to arrange for a solar engineer to visit to establish whether the fault lies with the solar inverter or with the grid.

Why do inverters have two input voltage options?

The third and most distinctive advantage is the higher efficiency of inverters at higher input voltages. If you see the datasheet of the inverters with two input voltage options they are more efficient in converting higher input voltage to mains voltage than converting lower input voltage to the same mains voltage.

Can a high voltage inverter hook up more than one panel?

Higher voltage does not mean that you could go as high as you want or you could hook as many panels as you have in series. You should look at the max input voltage rating of the inverter you are going to use and the max series voltage of the panels.

What voltage is a power inverter?

Invreter.com online store provides different voltage of power inverters: 12V, 24V, 48V power inverter and car inverter. Cheak the price list as shown below and choose the power inverter to meet your need. Net. Weight

Update Information

- High voltage and low current inverter

- Does the inverter have high voltage and high current

- Price of high voltage inverter

- Household Appliances High Voltage Inverter

- 12v inverter voltage high

- High voltage MOS inverter

- Processing high voltage inverter

- Saudi Arabia High Voltage Inverter Customization

- 100kv ultra high voltage inverter price

- Construction site low voltage to high voltage inverter

- High voltage inverter charging and discharging

- High voltage inverter discharge

- Photovoltaic high voltage inverter

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

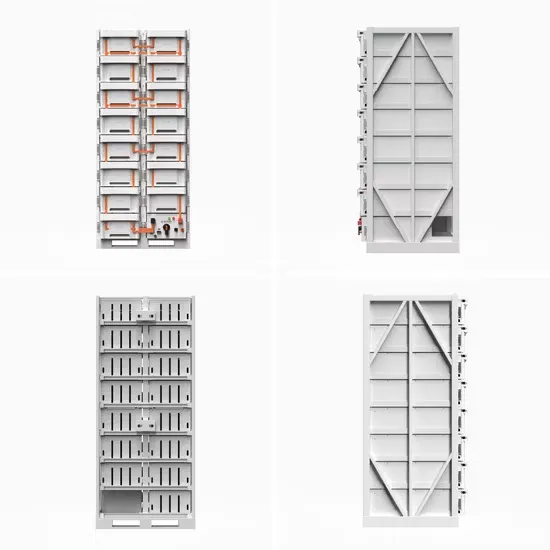

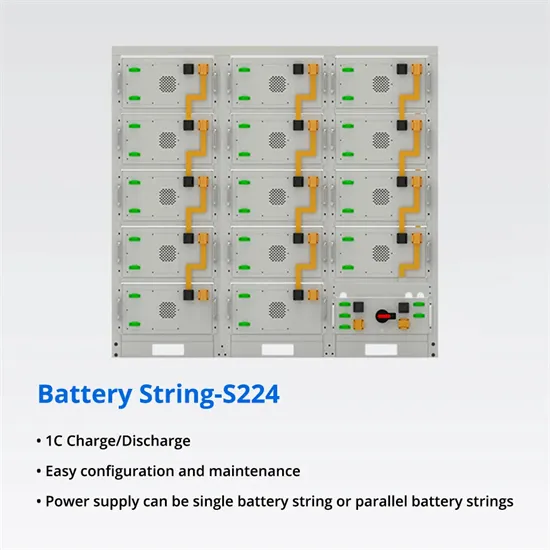

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.