Low Voltage Inverter: Definition, Function, And Applications

3 days ago · A low voltage inverter is an electronic device that converts direct current (DC) into alternating current (AC) with a relatively low input voltage, usually below 1000 volts. This is in

High-voltage VS Low-voltage Inverters: What''s the difference?

May 14, 2025 · High-voltage inverters are designed to work with DC voltages typically ranging from 150V to 600V or even more. They are common in larger residential or commercial solar

A Low to High Voltage Tolerant Level Shifter for Low

Mar 7, 2022 · the interface of a low-voltage and high-voltage gates. The level shifter is a key circuit component in multi-voltage circuits and has important implementation [15]. For a chip

Comparison and Analysis of High Voltage Inverter and Low Voltage

Jul 28, 2022 · Adjustable output frequency AC motor drives with voltage levels below 690V are classified as low-voltage inverters. With the continuous maturity of low-voltage inverter

What You Need To Know About a High Volt Inverter

Aug 16, 2025 · A high-voltage inverter is designed to convert DC power into AC at a higher voltage than a standard inverter. It can accept inputs from high-voltage power sources and

Converting DC to AC: Basic Principles of Inverters

May 28, 2024 · This article investigates the basic principles of inverters, different types of DC-to-AC conversion, and common applications for generating AC

The Role of High Input Voltage Inverters in Modern Energy

Feb 25, 2024 · As the world transitions towards renewable energy sources, high input voltage inverters have emerged as a crucial component in modern energy solutions. With their ability

Low-voltage VS High-voltage Inverters: What''s the Difference

Inverter technology serves as the backbone of modern power conversion systems, facilitating the seamless transformation of DC to AC electricity. The distinction between low-voltage (LV) and

The Technology Behind High Input Voltage Inverters

Feb 22, 2024 · This ensures the longevity and reliability of connected loads. In conclusion, high input voltage inverters have revolutionized the power conversion landscape. Their ability to

Is there a difference between a high voltage inverter and a low voltage

Jan 5, 2024 · The choice between low-voltage and high-voltage hybrid inverters depends on system size, power requirements, and availability and investment opportunities. Low voltage is

Components and Functions of Low-Voltage Inverters in

Aug 30, 2024 · Learn about the core components and key functions of low-voltage inverters and how to improve industrial automation efficiency through speed control, energy saving and

Whats is a High Voltage Hybrid inverter? What are Key

Aug 8, 2024 · Explore the pivotal differences between high and low voltage hybrid inverters and how these variations can influence your choice in sustainable energy solutions.

An advanced guide to Understanding DC to AC inverters

Apr 4, 2024 · It is a mechanism that lets you use low-frequency output signals. 3. OUTPUT FILTER In this step, the output filter removes high-frequency structure from the PWM wave.

High-voltage VS Low-voltage Inverters: What''s the difference?

When you hear the terms high-voltage and low-voltage inverters, you might wonder: does it really matter which one you choose? If you''re setting up a solar power system, buying a battery

Detailed explanation of the method for converting high-voltage

Apr 12, 2024 · The following are several methods to convert high-voltage AC power into low-voltage DC power.1. The principle of converting high-voltage AC to low-voltage DCIn DC

Three Level PWM DC/AC Inverter Using a Microcontroller

Jan 17, 2020 · o it is necessary to that devices can use. A low voltage DC source is inverted into a high voltage AC source in a two-step process. d up usin formed C source to AC at low voltage

Whats is a High Voltage Hybrid inverter? What are Key

Aug 8, 2024 · Explore the pivotal differences between high and low voltage hybrid inverters and how these variations can influence your choice in sustainable energy solutions. Understanding

6 FAQs about [Can the inverter convert high voltage into low voltage ]

How to turn off a low voltage inverter?

When it comes to turning off a low voltage inverter, the ways I see to do it are: pushing the power button on the inverter; disconnecting the DC power from the inverter; disconnecting the AC load from the inverter. IMO you should probably have twice the amp hours in the battery bank.

What happens if the input is low (0) in an inverter?

When the input to an inverter is LOW (0), the output is inverted, meaning it becomes HIGH (1).

Why do inverters trip off if it rains?

High voltage DC rated isolators and breakers are more expensive and difficult to source. Finally, if your panels happen to leak when it rains, there is a tendency for this leakage current to push up the bus voltage, so inverters can trip off with fault code 08 (bus voltage too high).

How do low frequency inverters work?

Low frequency inverters work with internal transformers, heavy metal cores and copper windings, which are generally more robust, and have more grunt to run motorised equipment.

What is a high frequency inverter?

For your fridge compressor, washing machines, pumps, etc. this type of inverter can handle a higher start-up surge that is caused by the magnetic windings in an electro-motor. High frequency inverters run with fancier electronics doing high-speed switching to achieve a 230V output.

Why do solar panels have a low voltage?

in solar panels, low voltage forces thicker cables to be used due to voltage drop. On the other hand, if the panels are not all oriented exactly in the same position, it is convenient to use more strings, that way you will have low tension.

Update Information

- High voltage and low current inverter

- Construction site low voltage to high voltage inverter

- Household high voltage off-grid inverter

- Wind and solar storage and charging high and low voltage

- AC side low voltage inverter protection

- The difference between high voltage lithium battery pack and low voltage lithium battery

- High voltage inverter outdoor large capacitor

- Solar communication base station China high and low voltage distribution cabinet price

- Does the inverter have high voltage and high current

- Can the inverter change to high voltage

- Inverter rear bridge output voltage is too low

- Inverter has good high frequency and good low frequency

- Nicaragua low voltage inverter manufacturer

Solar Storage Container Market Growth

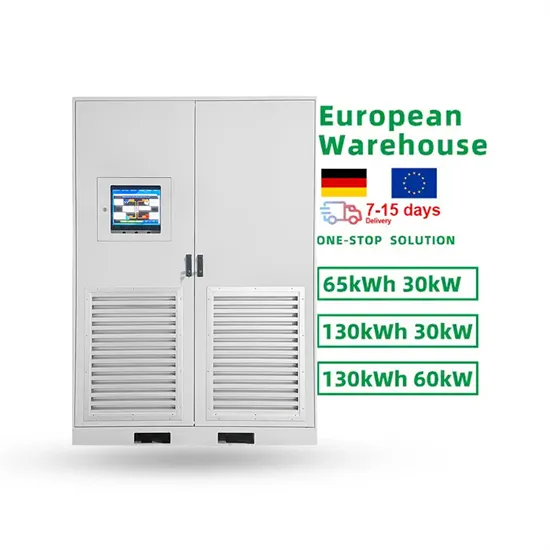

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

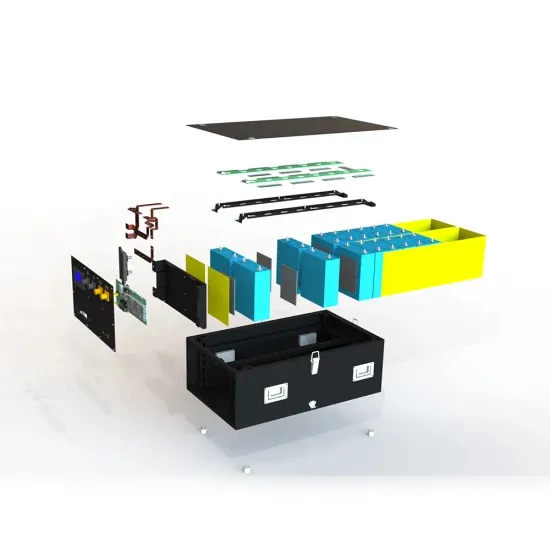

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.