High Voltage Solutions in HEV/EV Part II:

Aug 19, 2025 · What will I get out of this session? Purpose: To provide an overview of complete high voltage power solutions in DC-DC Conversions and Tractions Inverters Introduction

How to Modify a Step-down Converter to the Inverting

Sep 12, 2023 · When looking for a DC/DC converter to create a negative voltage, in many cases you will use a step-down converter in the inverting buck-boost topology. While dedicated

Analysis of a High Step-Down DC/DC Converter

Jul 30, 2021 · Abstract: This paper presents a novel high step-down dc/dc converter topology with a single inductor for 48V data center applications. Distinguished from conventional dc/dc

LOW POWER HIGH VOLTAGE STEP-DOWN CONVERTER

Mar 12, 2019 · These converters work in the first (step-down) and in the second (step-up) quadrant of the four-quadrant load diagram. This diagram is in Figure 1 and it is used in power

A Soft-Switching High Step-Down Regulated DC–DC

Dec 10, 2024 · This article proposes a soft-switching high voltage step-down ratio hybrid switched-capacitor converter with voltage regulation capability and their corresponding phase

HIGH INPUT VOLTAGE STEP-DOWN DC-DC

Mar 3, 2004 · High-to-low DC-DC converters operating at input voltages up to three times as high as the maximum voltage that can be directly applied across the terminals of a MOSFET are

Recent advances of step-up multi-stage DC-DC converters: A

Jun 1, 2025 · Among these conversion units, the step-up DC-DC converters occupy a pivotal role, elevating the DC voltage levels and facilitating interactions between converters and circuits.

Isolated high step‐down DC–DC converter with

Sep 11, 2023 · This paper proposed an isolated high-efficiency, high step-down converter for an ultracapacitor charger, which can charge a 250 F ultracapacitor from 0 to 14.6 V with constant

High Voltage Solutions in HEV/EV Part II:

Aug 19, 2025 · What is th DC/DC Converter? The DC/DC converter provides transfer of energy between the higher voltage battery system and the lower voltage (typically 12V) systems. The

Single‐switch, integrated DC–DC converter for

Jun 17, 2019 · High-voltage step-down in non-isolated DC–DC converters can be obtained with distinct solutions e.g. tapped inductors [8], switched inductors

Voltage Converters & Power Inverters | RS

Buck DC-DC converter - named because it ''bucks'' against the input voltage, this device produces an output that is less than its input. Boost DC-DC converter - does the opposite to the Buck

Split-Capacitor-Based Isolated Double Step-Down DC-DC

Jul 11, 2024 · Abstract: This article introduces a novel isolated high step-down dc–dc converter. The introduced converter can offer the low voltage stress of power switches on the primary

AC/DC & DC/DC converters (integrated FET)

Aug 13, 2025 · Our AC/DC and DC/DC converters feature a controller with one or more integrated field-effect transistors (FETs), striking a balance between design flexibility and ease of use.

Isolated High Step-up DC–DC Converter with Integrated

May 12, 2025 · This paper proposes an isolated high step-up PWM dc–dc converter that incorporates all four required advantages for DC micro-grid and micro-inverter applications.

6 FAQs about [High Voltage DC Step-Down Inverter]

Can a step-down DC-DC converter be used as an inverter?

When using a step-down DC-DC converter as an inverter, there are some limitations. The voltage difference between the input and the negative output must be less than the step-down DC-DC converter's maximum operating input voltage. In essence, a step-down DC-DC converter with maximum input of 12V can be used to convert 5V to -7V, but not more.

What is a high step-down DC-DC converter?

Abstract: This article introduces a novel isolated high step-down dc–dc converter. The introduced converter can offer the low voltage stress of power switches on the primary side. The introduced converter also achieves a zero-voltage-switching turn-on for all power switches and avoids the transformer saturation problem.

How to obtain high-voltage step-down in non-isolated DC–DC converters?

High-voltage step-down in non-isolated DC–DC converters can be obtained with distinct solutions e.g. tapped inductors [ 8 ], switched inductors and/or switched capacitors [ 9 ], and coupled inductors [ 10 ].

What is a step-up DC-DC converter?

Among these conversion units, the step-up DC-DC converters occupy a pivotal role, elevating the DC voltage levels and facilitating interactions between converters and circuits. However, the multistage DC-DC converters, prevalent in large-scale industries, offer higher voltage gains and power density.

What are the results of high step-down DC/DC converters with a single inductor?

Simulated results of high step-down dc/dc converters with a single inductor as a function of output power: (a) power efficiency and (b) output voltage. 0.7 and D = 0.4, respectively.

Can a step-down DC-DC converter convert 5V to -7V?

In essence, a step-down DC-DC converter with maximum input of 12V can be used to convert 5V to -7V, but not more. In addition, the minimum input voltage of the inverting circuit must be greater than the minimum operating voltage of the step-down IC, minus one diode drop. That is because on start-up, there is initially no negative output voltage.

Update Information

- High voltage inverter charging and discharging

- Price of high voltage inverter

- High voltage grid-connected inverter communication method

- Working function of high voltage inverter

- High frequency inverter input voltage

- 100kv ultra high voltage inverter price

- Can t the high voltage of the inverter be adjusted to a lower voltage

- Inverter outputs high current and high voltage

- Inverter DC voltage measurement exceeds range

- EK High Voltage Inverter

- Saudi Arabia High Voltage Inverter Customization

- Processing high voltage inverter

- Replace the inverter high voltage device

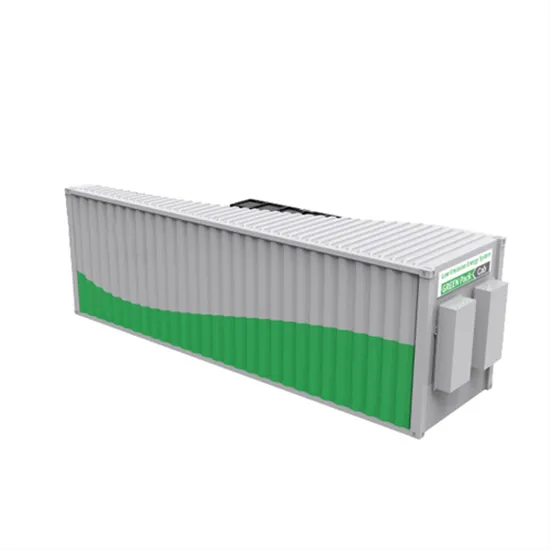

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.