Application Analysis of High

Aug 18, 2025 · High-voltage inverters employ a cascaded multilevel topology, producing an output waveform that closely approximates a sine wave. They can directly output high-voltage AC

The Role of High Input Voltage Inverters in Modern Energy

Feb 25, 2024 · As the world transitions towards renewable energy sources, high input voltage inverters have emerged as a crucial component in modern energy solutions. With their ability

High Voltage vs Low Voltage

May 31, 2022 · If this doesn''t fit, please ignore. If you really meant low frequency vs high frequency, then compare it in layman''s terms to an old-school muscle car with a big engine

Comparison and Analysis of High Voltage Inverter and Low Voltage

Jul 28, 2022 · Adjustable output frequency AC motor drives with voltage levels below 690V are classified as low-voltage inverters. With the continuous maturity of low-voltage inverter

Performance of Integrated High Voltage Gain DC-DC

Sep 23, 2024 · Environmental sustainability is crucial, especially in electrical power generation using renewable sources like photovoltaic or fuel cells. However, these sources, while

High Voltage Inverter: Unlocking the Potential of High

Aug 17, 2025 · Due to its ability to handle high voltages, its use allows the operation of devices with large loads while ensuring precise control and optimal energy efficiency. This article will

A Software-Defined Stacked Multilevel Motor Drive

Oct 17, 2022 · Additionally, directly switching high voltage can generate significant conducted and radiated EMI. Multilevel typologies are often used to distribute voltage stress over many low

Whats is a High Voltage Hybrid inverter? What are Key

Aug 8, 2024 · Explore the pivotal differences between high and low voltage hybrid inverters and how these variations can influence your choice in sustainable energy solutions.

Simple High Voltage Generator: Low Voltage DC In, up to 30

Jan 30, 2021 · The high voltage section on the right may actually be constructed as a voltage multiplier rather than a single winding with multiple HV diodes. The rectifiers or multiplier,

Demystifying high-voltage power electronics for solar

Apr 1, 2023 · Increased eficiency, reduced cost, and reliability are three areas where renewable-energy systems can achieve grid parity. One of the key subsystems in PV generation is the

36V to 220V Inverter for Construction Sites to 220V Ac Low Voltage

welcome to taobao purchase v to v inverter for construction mites to v ac low volstage to high volstage converter boost transfer, taobao hundreds of millions of hot selling goods, official

Inverter Transformers for Photovoltaic (PV) power plants:

Dec 22, 2022 · To step up the output voltage of the inverter to such levels, a transformer is employed at its output. This facilitates further interconnections within the PV system before

THE DESIGN AND CONSTRUCTION OF AN INVERTER

The working principle of an inverter can be explained with the help of a complete circuit diagram. This is a voltage driven inverter because the voltage source is connected through semi

Comparison and Analysis of High Voltage Inverter and Low Voltage

Jul 28, 2022 · With the continuous maturity of low-voltage inverter technology, the application of low-voltage inverter determines its different classification. From a technical point of view, the

What is the Difference Between the Deye HV Hybrid Inverter

Oct 23, 2024 · Hybrid inverters are an integral part of any solar energy system, as they manage the flow of energy between your solar panels, battery storage,Generator, and the grid. Deye, a

High Density Auxiliary Power Supply Using a SiC

Apr 1, 2023 · ABSTRACT A high-voltage to low-voltage backup auxiliary power supply has become prevalent in automotive powertrain applications. This application report discusses key

How to Design High-voltage Systems with Higher

Aug 8, 2023 · Overcome high-voltage design challenges with reliable isolation technologies Read our white paper to learn about common high-voltage galvanic isolation concerns and methods,

Is there a difference between a high voltage inverter and a low voltage

Jan 5, 2024 · The choice between low-voltage and high-voltage hybrid inverters depends on system size, power requirements, and availability and investment opportunities. Low voltage is

The elevator slips of low voltage inverters-VEICHI

Oct 31, 2018 · Slipping occurs while running up, and a multimeter is used to measure the voltage of the three-phase grid below 70% of the rated voltage during the operation of a large number

Differences and similarities between low-voltage inverters and high

The choice between a low-voltage inverter and a high-voltage inverter often depends on specific application requirements, including the scale of the operation, efficiency concerns, and safety

Whats is a High Voltage Hybrid inverter? What are Key

Aug 8, 2024 · The primary difference between high and low voltage hybrid inverters lies in their compatibility with the battery charging voltage. High voltage inverters work with batteries that

6 FAQs about [Construction site low voltage to high voltage inverter]

What is a high voltage grid connected inverter?

The high-voltage grid-connected inverter has a high-voltage output capacity. The AC grid-connected voltage levels of 1100V DC high-voltage inverters are generally 480Vac, 500Vac, 540Vac, etc., and the AC grid-connected voltage level of 1500V DC high-voltage inverters is 800Vac.

What is the voltage level of a low-voltage grid connection system?

The voltage level of the low-voltage grid connection system accessing the power grid is usually 380V (three-phase) or 220V (single-phase), which is exactly the common voltage in our daily electricity consumption.

How to invert low voltage DC power?

The method, in which the low voltage DC power is inverted, is completed in two steps. The first being the conversion of the low voltage DC power to a high voltage DC source, and the second step being the conversion of the high DC source to an AC waveform using pulse width modulation.

How a transformer is used in a PV inverter?

To step up the output voltage of the inverter to such levels, a transformer is employed at its output. This facilitates further interconnections within the PV system before supplying power to the grid. The paper sets out various parameters associated with such transformers and the key performance indicators to be considered.

What are inverters used for?

Inverters are used for many applications, as in situations where low voltage DC sources such as batteries, solar panels or fuel cells not be converted so that devices can run off of AC power. One example of such a situation would be converting electrical power from a car battery to run a laptop, TV or cell phone.

Why should you choose a low-voltage grid connection system?

The low-voltage grid connection system does not require complex power transmission equipment, and installation and maintenance are also more convenient. For residents and small industrial and commercial users, the low-voltage grid connection system is undoubtedly a more economical and practical choice.

Update Information

- Can the inverter convert high voltage into low voltage

- High voltage and low current inverter

- High voltage inverter 28000

- High voltage inverter model

- 100kv ultra high voltage inverter price

- High voltage inverter charging and discharging

- Inverter has good high frequency and good low frequency

- Household Appliances High Voltage Inverter

- Photovoltaic high voltage inverter

- Sri Lanka high voltage inverter manufacturer

- High frequency inverter adjusts output voltage

- High frequency inverter input voltage

- High Voltage DC Step-Down Inverter

Solar Storage Container Market Growth

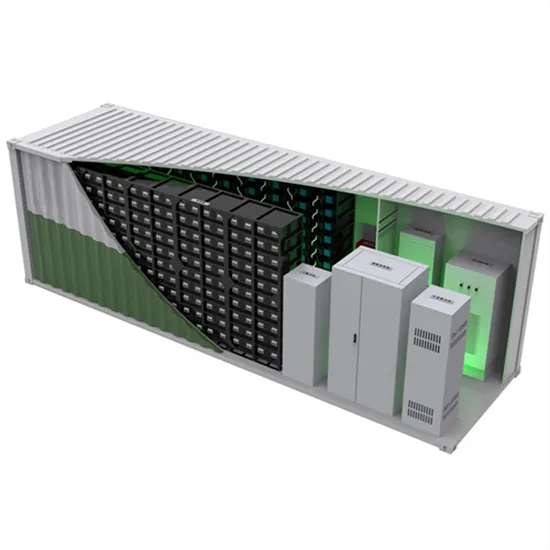

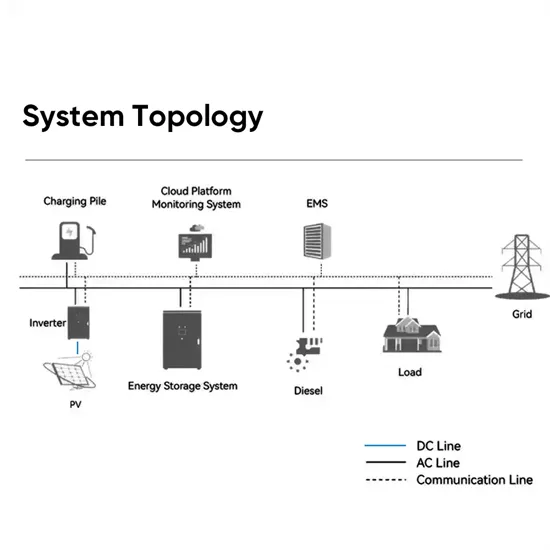

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

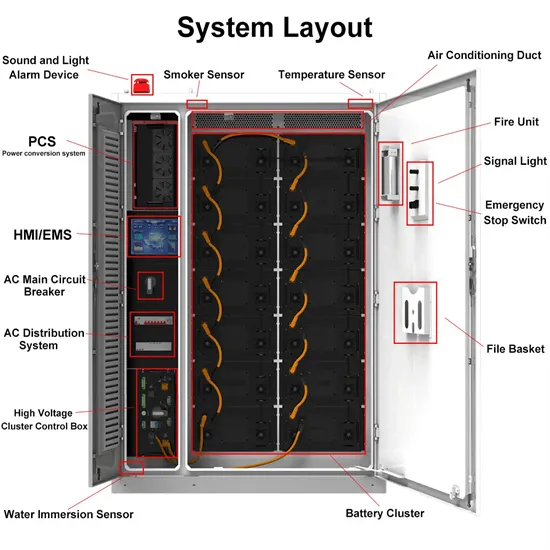

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.