Comparison and Analysis of High Voltage Inverter and Low Voltage

Jul 28, 2022 · WP4000 frequency conversion power analyzer can realize the input, output and efficiency test of high voltage frequency converter with voltage of 10kV and current of 7000A

Best High Voltage Power Inverters for Reliable Mobile and Outdoor Power

4 days ago · August 22, 2025 Power inverters are essential for converting DC battery power into useful AC power, enabling you to run household electronics, tools, or outdoor gear from

What You Need To Know About a High Volt Inverter

Aug 16, 2025 · A high-voltage inverter is designed to convert DC power into AC at a higher voltage than a standard inverter. It can accept inputs from high-voltage power sources and

High-voltage traction inverter | electric vehicle | Eaton

Sep 20, 2020 · The high-voltage inverter converts direct current (DC) from the batteries or generator to alternating current (AC) to power the traction drive motors. With Eaton''s

Driving the future of HEV/EV with high-voltage solutions

Apr 1, 2023 · In this white paper, I will discuss the value of high voltage and SMPS in two subsystems – an on-board charger (OBC) and a traction inverter – with an emphasis on the

High Voltage Solar Inverter DC-AC Kit

Sep 3, 2014 · This document describes the implementation of the inverter kit that used as a DC-AC part of the High Voltage Solar Inverter DC-AC Kit. The kit has a nominal input of 400-V

HEV/EV Traction Inverter Design Guide Using Isolated

Apr 1, 2023 · Zooming in to the traction inverter system reveals multiple blocks including the power management IC (PMIC) and the microcontroller (MCU), the high-power IGBT or SiC

Automotive, High-Power, High-Performance SiC Traction

May 5, 2025 · The UCC142140-Q1 integrates a high-efficiency, low-emissions isolated DC/DC converter for powering the gate drive of SiC or IGBT power devices in traction inverter motor

High Voltage Large Capacity Inverter Evaluation

The PXB series is designed for high-voltage, large-capacity inverters and other electrical components. It supports voltages up to 1500 V and power up to 200 kW * (power over 200 kW

High power T-type-based multi-level inverter for electric

Nov 1, 2023 · Multi-level inverters became very popular in the last decade. Typically, they are used in high power and high voltage applications such as converters for ships, electric trains,

High Voltage Inverter: Unlocking the Potential of High-Power

Aug 17, 2025 · High voltage inverter is an important device in the sustainability of renewable energy systems on a medium to large scale. Due to its ability to handle high voltages, its use

High-voltage inverter | EV traction inverter | Eaton

Apr 1, 2025 · The high-voltage inverter converts direct current (DC) from the batteries or generator to alternating current (AC) to power the traction drive motors. With Eaton''s established

High Voltage 800V SiC Inverter | Valeo for

Sep 2, 2024 · What is a High Voltage Inverter? The inverter is the brain at the heart of the powertrain, it controls the electric motor. It converts Direct Current

6 FAQs about [High voltage power inverter]

What is a high voltage inverter?

High voltage, three-phase energy storage for commercial applications. The inverter series, which boasts a maximum charge/discharge current of 100A+100A across two independently controlled battery ports, has 10 integrated MPPTs with a string current capacity of up to 20A – ensuring unmatched power delivery.

What is high frequency power inverter?

The high voltage frequency converter integrate the most advanced motor vector control algorithm, high control precision, fast response, low frequency, high torque. Our high frequency power inverter can be applied to energy-saving speed regulation and process improvement of high-voltage asynchronous motors and synchronous motors.

What is a high power switch in an inverter?

The high-power switches are the most critical component in the inverter as they control the flow of current to the motor to generate motion. As such, the switches' are monitored and protected by sensing their temperature, voltage and current throughout their operation.

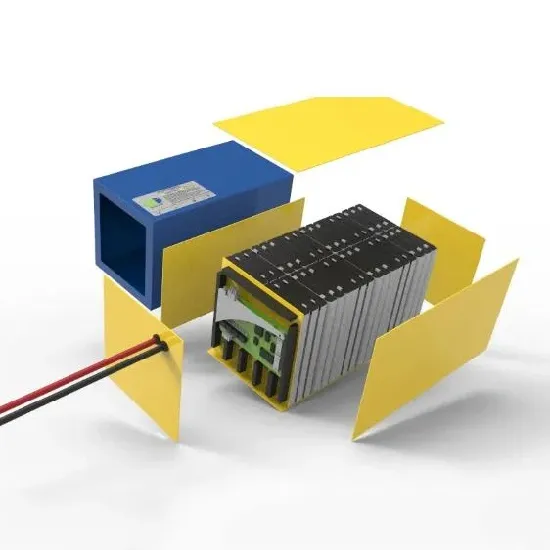

What are the parts of a high frequency power inverter?

The high frequency power inverter includes two parts, main circuit and control circuit. The main circuit includes an inverter DC power supply, high frequency high voltage transformers, IGBT bridge inverter, protection circuits, high frequency high voltage silicon stack (Rectifier) , etc.

What is micno high voltage inverter?

MICNO high voltage inverter adopts the most mainstream power unit series technology, with DSP+ARM+FPGA three-core processor as the control core. The high voltage frequency converter integrate the most advanced motor vector control algorithm, high control precision, fast response, low frequency, high torque.

Who develops high voltage inverter systems for electric vehicles?

The vehicle manufactures and automotive tier 1 suppliers develop inverter systems for electric vehicles. Discussions were held with their design and research teams during direct meetings to understand future developments. Through these discussions, along with our own research, there are some clear high voltage inverter trends in the EV market. 3.

Update Information

- Wide voltage and high power inverter

- High voltage power supply full bridge inverter price

- High voltage power inverter

- Can the inverter convert high voltage into low voltage

- High frequency inverter input voltage

- High frequency inverter adjusts output voltage

- High quality wholesale 1500 power inverter supplier

- Austria high frequency power inverter

- Inverter for non-high voltage power users

- Nairobi High Power Inverter Manufacturer

- High power inverter

- Saudi Arabia High Voltage Inverter Customization

- Processing high voltage inverter

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.