LOW-LEAKAGE AND HIGH-SPEED TRIPLE-THRESHOLD

Aug 5, 2016 · Abstract: Switching speed, active power consumption, standby leakage current, and silicon area are major concerns in buffer design. A new Skewed-IO cell with two split inputs

The Difference Between High Voltage Converters and Inverters

Dec 4, 2024 · Key Differences Between Converters and Inverters While both converters and inverters are integral to energy transformation, they serve distinct purposes. Converters

High Voltage Solar Inverter DC-AC Kit

Sep 3, 2014 · Among the various inverter systems, there are two different types. The first type is the voltage output type, which outputs AC voltage as a voltage source. For example, the

Common-mode transient immunity for isolated gate

Nov 2, 2015 · The inverter outputs switch between ground and VDC at the PWM frequency, however, the output current is filtered either by the LC filter or motor inductance. Figure 5

A review on topology and control strategies of high-power inverters

Feb 15, 2025 · In large-scale applications such as PV power plants, "high-power" in medium voltage (MV) inverters is characterized by the use of multilevel inverters to enhance efficiency

A Single-Switch Dual-Constant-Output Class-E Inverter With

Jul 25, 2024 · This article presents a single-switch dual-output class-E inverter with a coupled-inductor design. By using integrated series and parallel resonant techniques, a constant

DC HOUSE 48V 2000W Inverter Charger for Golf Cart, RV

2-in-1 Inverter Charger | 48V 2000W Pure Sine Wave | 48V 25A Lithium Charger | CE Certified | Dual Cooling Fans | 8-Layer Safety Protection ⚡ 2-in-1 Inverter & Charger The DC HOUSE

ken-system: Load-independent Class-E Inverter with Constant-Current

Jan 11, 2024 · This research proposes a reconfigurable load-independent class-E inverter with a parallel resonant structure, which can achieve constant current (CC) and constant voltage

A single-phase seven-level ANPC inverter with hybrid

Mar 20, 2025 · Switched-capacitor (SC) multilevel inverters (MLIs) are widely used in a variety of applications due to their ability to boost voltage and balance capacitor voltage. High efficiency

3-Phase Inverter Ref Design Using Gate Driver With Built

Dec 6, 2017 · Figure 1 shows atypical application of a three-phase inverter using six isolated gate drivers. Note that each phase uses a high-side and a low-side IGBT switch to apply positive

International Journal of Circuit Theory and Applications

Jun 18, 2025 · This work proposes a single-phase simplified split-source inverter with dual output and a reduced common mode voltage (CMV). The topology consists of four power electronic

240v inverter solar – regions of use, benefits and Sunchees

Aug 15, 2025 · A 240v inverter solar system is not just about voltage—it''s about matching regional standards, powering high‑demand appliances and reducing wiring losses.

High-Voltage, Large-Current, and High-Power Measuring

Jul 27, 2016 · Demand for high-voltage, high-power converters capable of producing high-quality waveforms while utilizing low voltage devices and reduced switching frequencies has led to

High-Voltage, Large-Current, and High-Power Measuring to

Solar inverters with high voltage, large current, and high power are becoming increasingly common. This is done to increase power generation efficiency and reduce installation costs.

Driving the future of HEV/EV with high-voltage solutions

Apr 1, 2023 · In this white paper, I will discuss the value of high voltage and SMPS in two subsystems – an on-board charger (OBC) and a traction inverter – with an emphasis on the

A novel control strategy of the inverter with sinusoidal voltage

The authors have previously proposed a novel inverter with sinusoidal, voltage and current outputs (1992). In the novel inverter, the design of a high-pass filter inserted in the feedback

The current status and development of DC/AC

Apr 14, 2023 · The replacement of the industrial frequency transformer in the low-frequency link inverter process technology with a high-frequency transformer

SNx4LS06 Hex Inverter Buffers and Drivers With Open

Jul 31, 2025 · The SNx4LS06 devices feature high-voltage, open-collector outputs to interface with high-level circuits (such as MOS), or for driving high-current loads, and also are

6 FAQs about [Inverter outputs high current and high voltage]

What is a high power inverter?

In the context of PV power plants, the "high-power" classification for multilevel inverters usually applies to systems operating in the MW range, incorporating medium voltage levels of 2.3–13.8 kV to optimize energy transmission efficiency and support reliable system performance .

How to achieve high output power levels in ChB-based inverters?

In order to attain elevated output power levels, obviate the necessity for low-frequency transformers, generate multilevel output voltage, and implement distributed MPPT, a novel three-phase topology has been introduced in Ref. tailored for CHB-based inverters.

What is a high power inverter with a NPC topology?

The high-power inverter with a NPC topology, also known as a three-level inverter, is a type of multilevel converter. In contrast to traditional two-level inverters, which have two voltage levels (positive and negative), this inverter has an additional intermediate voltage level known as the neutral point .

What are the applications of control systems in high-power inverters?

One of the application of control systems in high-power inverters is to increase the speed and accuracy in achieving MPPT. Control algorithms continuously examine the input of the inverter and adjust its operational parameters to extract the maximum available power . Another essential factor is computational complexity.

Are high-power ChB inverters able to control output power?

One of the inherent issues in high-power CHB inverters is the imbalance in the output power, leading to instability and reduced current in grid-connected systems. Therefore, an adaptive control technique has been proposed to regulate the output power in these converters.

What are the different types of inverter systems?

Among the various inverter systems, there are two different types. The first type is the voltage output type, which outputs AC voltage as a voltage source. For example, the inverter in the UPS system is a typical voltage-type inverter. The other type is the current type, which outputs AC current in a specified power factor.

Update Information

- Does the inverter have high voltage and high current

- The inverter outputs high voltage with excess power

- High voltage inverter sm

- Difference between voltage type and current type PWM inverter

- High voltage power inverter

- Voltage outer loop current inner loop lcl inverter

- The role of high voltage three-phase inverter

- Household high voltage off-grid inverter

- 12v inverter voltage high

- Household Appliances High Voltage Inverter

- Price of high voltage inverter

- Wide voltage and high power inverter

- Photovoltaic high voltage inverter

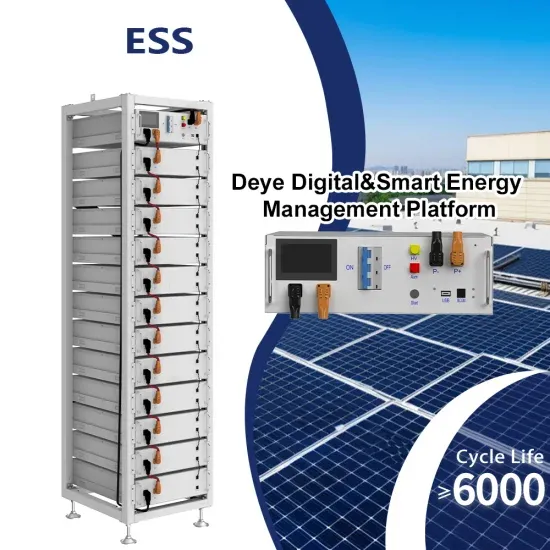

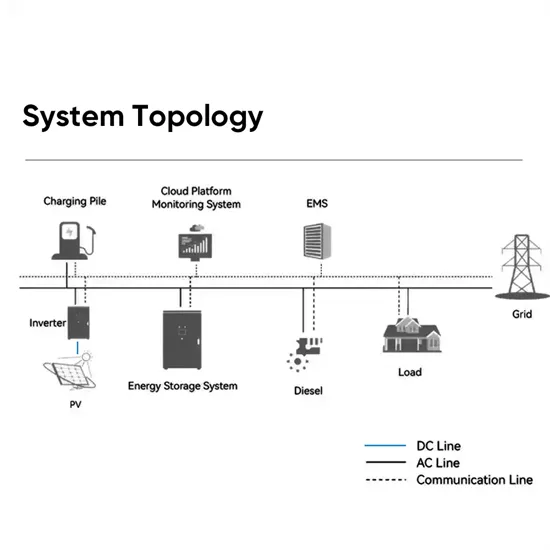

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.