Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Designing a lithium-ion battery pack is a complex and multifaceted process that requires a deep understanding of the components, configurations, and safety considerations

Technology Program Manager

5 days ago · M.S. in Chemical, Electrical, or Mechanical Engineering Minimum of 5+ years of experience in lithium-ion battery technology and systems. Expertise in lithium-ion battery

Nairobi Lithium battery crushing and recycling equipment''s

Xingmao Machinery, Innovative concept and technology empowerment, after years of technological innovation in Lithium battery crushing and recycling equipment series products,

Understanding the Lithium-Ion Battery Manufacturing Process

Aug 5, 2025 · This means that during the battery''s operation, lithium ions move from the anode to the cathode through an electrolyte, and then back again when charging. The efficiency of this

Lithium Recycling Process in Kenya | Recycling Solutions.

Looking for an Lithium Recycling Process in Kenya? We provide efficient and eco-friendly recycling solutions to ensure safe battery disposal and resource recovery. Call Now: +91

The lithium-ion battery production process in Kenya

The battery cell formation is one of the most critical process steps in lithium-ion battery (LIB) cell production, because it affects the key battery performance metrics, e.g. rate capability, lifetime

Marula Mining to set up lithium-ion battery recycling plant in Kenya

Aug 5, 2025 · KENYA — UK-listed Marula Mining PLC has announced plans to establish a lithium-ion battery recycling and critical metals processing facility in Kenya through a

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Conclusion The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each

Miner backs Kenya''s first lithium-ion battery recycling plant

5 days ago · UK-based Marula Mining is investing in Kenya''s first lithium-ion battery recycling and critical metals recovery facility. The company is partnering with Nairobi''s WEEE Centre, a

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · The production of a lithium battery pack is a multifaceted process, involving several crucial steps to guarantee the final product''s quality and

Felicity 5kWh 48v Lithium Battery Pack With BMS

Long warranty period:3-5 years •Lithium Battery Iron Phosphate Battery • Support connected in parallel mode for expansion • Higher energy density, smaller volume for household. •

Marula Mining commits €500,000 to battery recycling project in Kenya

Aug 4, 2025 · The agreement involves an initial €500,000 investment from Marula''s wholly owned subsidiary, Marula Metals Processing Limited, to support the early-stage development of a

Nairobi Mobile phone lithium battery crushing and recycling

The idea of the novel design is OK! Xingmao Machinery, Strive for quality with originality, after years of technological innovation in Mobile phone lithium battery crushing and recycling

London-listed Marula Mining in deal to setup battery recycle plant in Kenya

Aug 4, 2025 · London Stock Exchange (LSE)-listed Marula Mining has entered into a partnership with Nairobi-based electronic waste management firm WEEE Centre Limited to establish a

Marula Mining, WEEE Centre partner to launch lithium battery

Aug 8, 2025 · Marula Mining PLC, a UK-listed mining and metals company, has revealed plans to set up Kenya''s first lithium-ion battery recycling and critical metals recovery plant.

Lithium Battery Pack Process: Assembly, Management and

The pack process of lithium battery involves many links such as the assembly, management and protection of battery cells, which has an important impact on the performance and safety of

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

Update Information

- Indian lithium battery pack processing

- Dominic lithium battery pack processing

- Berlin lithium battery pack processing

- Dakar lithium battery pack processing

- Lima Power Lithium Battery Pack Processing

- Lithium battery pack processing in Southern Europe

- Huawei lithium battery pack module automation

- San Salvador lithium battery production and processing

- Colombian lithium battery pack price

- 18V photovoltaic energy storage cabinet battery lithium battery pack

- Juba lithium iron phosphate battery pack

- 500ha lithium iron phosphate battery pack price

- Tuvalu energy storage lithium battery pack customization

Solar Storage Container Market Growth

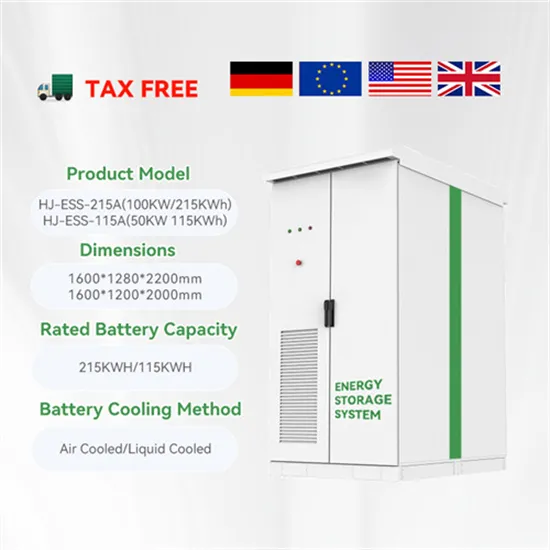

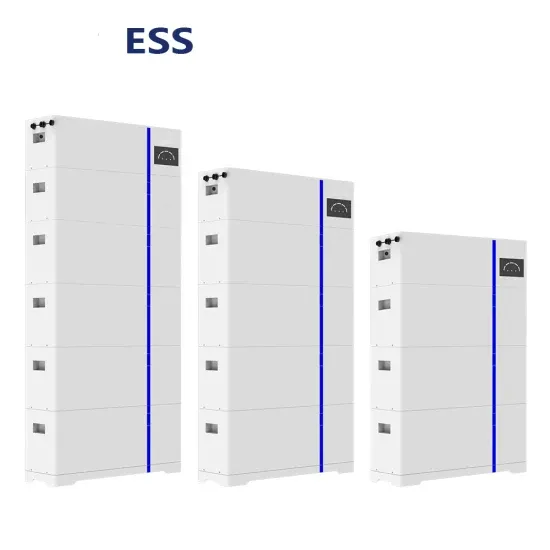

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.