Dominic lithium battery slurry production line

G MK3.0 series lithium battery slurry twin-screw continuous automatic production line, including powder metering and conveying system Lithium-ion battery (LIB) manufacturing involves 3

Lithium Battery Pack Process: Assembly, Management and

The pack process of lithium battery involves many links such as the assembly, management and protection of battery cells, which has an important impact on the performance and safety of

Lithium-Ion Battery Pack Processing Line: Process Flow and

Steps: Integrate welded cells with protection boards (PCM/BMS), insulation materials (e.g., fish paper, epoxy boards), and structural supports. Safety: Operators must wear electrostatic

Dominic 48v liquid-cooled energy storage lithium

The development content and requirements of the battery pack liquid cooling system include: 1) Study the manufacturing process of different liquid cooling plates, and compare the

Dominic new battery cell manufacturer

Where is Northvolt 2 battery made? NorthVolt Zwei (two), JV battery production in Salzgitter, Germany, for the electric vehicles of the Volkswagen Group. Start of production planned for

Lithium-ion Battery Manufacturing Front to End

Oct 2, 2022 · In a nutshell, it is the process through which the 4 main components of a battery (graphite anode + metal alloy cathode + separator + electrolyte

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · The production of a lithium battery pack is a multifaceted process, involving several crucial steps to guarantee the final product''s quality and

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Figure 1 introduces the current state-of-the-art battery manufacturing process, which includes three major parts: electrode preparation, cell assembly, and battery

Comprehensive Comparative Analysis of Deep Learning

Apr 28, 2024 · Comprehensive Comparative Analysis of Deep Learning-based State-of-charge Estimation Algorithms for Cloud-based Lithium-ion Battery Management Systems Dominic

A critical discussion of the current availability of lithium and

a Schematic depiction of a rechargeable zinc battery and lithium-ion battery. b Comparison of the cost of the battery components of the two battery systems (zinc on the left, lithium-ion on the

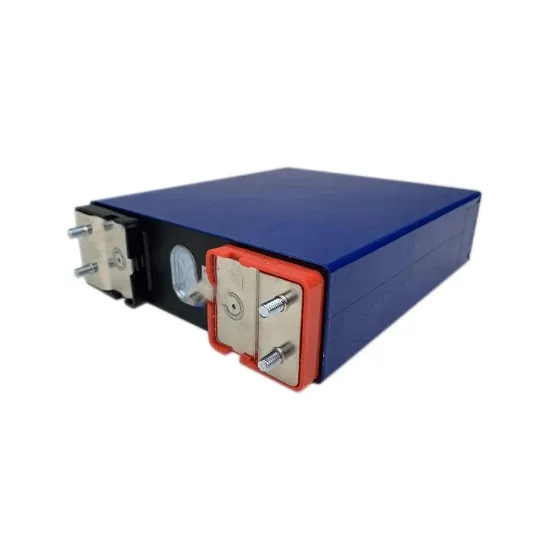

How much does Dominic lithium iron phosphate battery cost

The lithium iron phosphate battery (LiFePO 4 battery) or LFP battery (lithium ferrophosphate) is a type of lithium-ion battery using lithium iron phosphate (LiFePO 4) as the cathode material,

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Lithium-ion batteries – Current state of the art and

Dec 15, 2020 · Lithium-ion batteries are the state-of-the-art electrochemical energy storage technology for mobile electronic devices and electric vehicles. Accordin

Dominic lithium battery slurry production line

The demand for rechargeable lithium-ion batteries is growing fast and as a result, manufacturers have to meet challenging requirements for production quality and further battery development.

The Production Process of Cylindrical Lithium

Mar 8, 2025 · Uncover the detailed production process of cylindrical lithium - battery packs. Learn about key steps like cell selection, grouping, module assembly, BMS integration, and more.

PRODUCTION PROCESS OF A LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

LITHIUM-ION BATTERY CELL PRODUCTION PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

6 FAQs about [Dominic lithium battery pack processing]

What are the production steps in lithium-ion battery cell manufacturing?

Production steps in lithium-ion battery cell manufacturing summarizing electrode manufacturing, cell assembly and cell finishing (formation) based on prismatic cell format. Electrode manufacturing starts with the reception of the materials in a dry room (environment with controlled humidity, temperature, and pressure).

How are lithium ion battery cells manufactured?

The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode manufacturing and cell finishing process steps are largely independent of the cell type, while cell assembly distinguishes between pouch and cylindrical cells as well as prismatic cells.

What is a lithium battery pack?

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line: Cell Types Cells are the basic units that make up the battery pack, mainly divided into:

How to contact lithium battery pack engineering team?

Tel & Wechat: (0086) 158 6765 3608 Mr.Pan Our engineering team offers design solutions. The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser welders, testers, and automated handling systems for efficiency and precision.

How are lithium ion batteries processed?

Conventional processing of a lithium-ion battery cell consists of three steps: (1) electrode manufacturing, (2) cell assembly, and (3) cell finishing (formation) [8, 10]. Although there are different cell formats, such as prismatic, cylindrical and pouch cells, manufacturing of these cells is similar but differs in the cell assembly step.

What are the production processes of a battery pack?

Outer Packaging: Provides physical protection. Output Interfaces: For connecting the battery pack with external devices. Production processes cover cell selection and grouping, welding, assembly, aging testing, inspection, and packaging. Assembly Production Line The process flow of the PACK production line includes:

Update Information

- Nairobi lithium battery pack processing

- Lima Power Lithium Battery Pack Processing

- Zero cycle battery secondary lithium battery pack

- How much is the lithium iron phosphate battery pack

- Which lithium battery pack has the best price

- The role of lithium battery pack with inverter

- Alofi replaces lithium battery pack

- What is MOS for lithium battery pack

- Lithium iron phosphate battery pack 25 6v71 5ah

- Telecom site lithium battery pack 12v battery cabinet

- Production of lithium battery pack types

- Gaborone lithium battery pack

- Discharge capacity of lithium battery pack

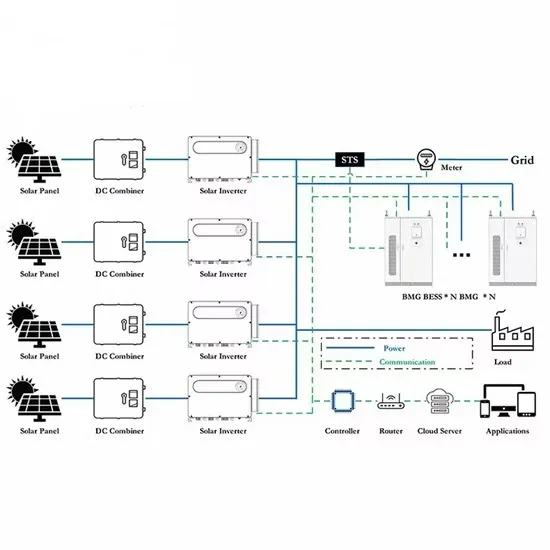

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.