A factory in San Salvador that makes negative electrode

The pursuit of new and better battery materials has given rise to numerous studies of the possibilities to use two-dimensional negative electrode materials, such as MXenes, in lithium

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

El Salvador lithium battery manufacturing company

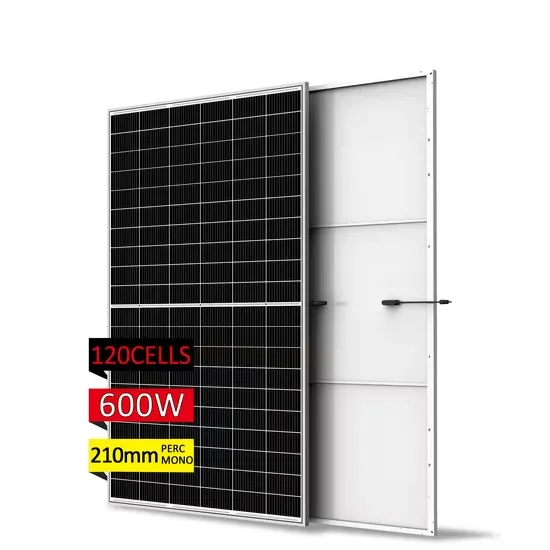

Demands of lithium battery manufacturing Thanks to their high energy density, lithium batteries are in high demand. As the need for electric vehicles, battery-operated machinery, and solar

San Salvador Lithium Battery Energy Storage Powering a

As San Salvador accelerates its clean energy transition, lithium battery storage stands as the backbone of reliable power management. From solar farms to hospitals, these systems deliver

San Salvador Lithium Battery Manufacturing Company

When it comes to its production process of custom lithium battery manufacturers, the lithium battery manufacturing process mainly includes batching, coating, sheeting, preparation,

Latest list of battery disposal companies in El Salvador

Our solution, through battery reuse and recycling and collaboration with battery recycling companies in India, empowers the energy storage industry to curtail the demand for fresh

San Salvador Lithium Battery Charging Cabinet

The new Justrite lithium ion battery charging and storage cabinet provides the ideal storage solution. Featuring ChargeGuard(TM) technology, this new cabinet was designed especially

Advanced lithium-ion battery process manufacturing

Summary Lithium-ion battery cell manufacturing depends on a few key raw materials and equipment manufacturers. Battery manufacturing faces global challenges and opportunities as

Can sticking to cultural concept improve the competitiveness

[ El Salvador Mobile phone lithium battery crushing and recycling equipment trusted the company], the culture thrives, the production and sales of Xingmao brand Mobile phone lithium

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Lithium-ion batteries (LIBs) have become one of the main energy storage solutions in modern society. The application fields and market share of LIBs h

Low-carbon production energy saving and efficiency

El Salvador Lithium battery crushing and recycling equipment rest assured that product suppliers Xingmao Machinery establish and improve environmental protection systems and implement

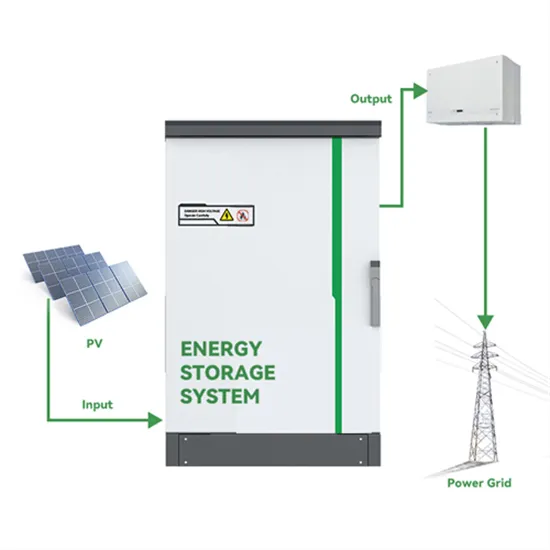

Batteries for conversion equipment produced in San Salvador

About Batteries for conversion equipment produced in San Salvador As the global shift towards renewable energy accelerates, the need for reliable and efficient energy storage has never

Culture promotes enterprises El Salvador Lithium battery

[ El Salvador Lithium battery crushing and recycling equipment trusted the company] -- The production and sales, Xingmao brand Lithium battery crushing and recycling equipment series

Lithium battery assembly San Salvador manufacturer

With 40 years of experience and state-of-the-art production capabilities, Alexander Battery Technologies supports OEMs to bring complex lithium-ion battery packs and battery

San Salvador Low Temperature Lithium Battery Project Address

A DRL-based Optimized Pulse Heating Strategy for Low-Temperature The lithium-ion battery (LiB) performance decreases sharply in cold climates, and charging at low temperatures is

Repeat customers are the foundation of San Salvador Lithium battery

Execution Excellence gets it done. Xingmao Machinery from an unknown small workshop to a Lithium battery crushing and recycling equipment series product brand enterprise with large

San Salvador new energy battery production process

Abstract. The battery cell formation is one of the most critical process steps in lithium-ion battery (LIB) cell production, because it affects the key battery performance metrics, e.g. rate

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Does San Salvador produce lithium batteries

The first rechargeable lithium battery was designed by Whittingham (Exxon) and consisted of a lithium-metal anode, a titanium disulphide (TiS 2) cathode (used to store Li-ions), and an

El Salvador new Lithium battery crushing and recycling

What is the key to victory? El Salvador new Lithium battery crushing and recycling equipment supplier enterprise Xingmao Machinery gave the answer: Go hand in hand to create brilliance,

Xingmao reminds: honesty is the key to cooperation with San Salvador

[San Salvador Mobile phone lithium battery crushing and recycling equipment Honesty and win-win] -- Xingmao Machinery Focus on research and development, quality firs, guide Xingmao

PRODUCTION OF LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The ''Production Process of a Lithium-Ion Battery Cell'' guide pro-vides a comprehensive overview of the production of different battery cell formats, from electrode

What are the battery lithium material factories in San Salvador

In this piece, we highlight four companies that represent key players in this ecosystem: Ganfeng Lithium: A leading Chinese lithium mining company that has evolved into refining and

Break through shackles and move forward Lithium battery

It is difficult to make our Lithium battery crushing and recycling equipment product win customers better, but it is imperative! This is not just one Lithium battery crushing and recycling

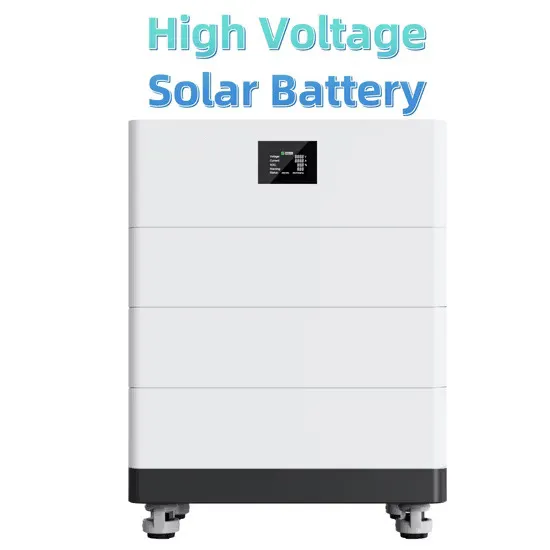

San Salvador Solar Lithium Battery Customization Factory

ProLogium Opens the World''''s First Giga-level Solid-State Lithium Ceramic Battery Factory "The Time is Now." New Technological Structure Opens a New Chapter in the Battery IndustryOn

Understanding the Lithium-Ion Battery Manufacturing Process

Aug 5, 2025 · Intro Creating a lithium-ion battery is like piecing together a complex puzzle where every part plays a crucial role in achieving the final goal. These batteries, which power

San Salvador Lithium battery crushing and recycling

The idea of the novel design is OK! Xingmao Machinery, China export products, after years of technological innovation in Lithium battery crushing and recycling equipment series products,

Xingmao Machinery New products in China, San Salvador Lithium battery

North America Module disassembly equipment supplier Xingmao Machinery San Salvador Lithium battery disassembly and utilization equipment cross-border business service station,Its factory

San Salvador lithium battery project bidding

Should lithium carbonate be accelerated in the Andes? Fernandes pointed out that this should change, as China and Russia have committed to accelerating lithium carbonate production in

LIST OF BATTERY MANUFACTURERS IN SAN SALVADOR

Who makes lithium ion batteries? One is start-up companies, and the other is established suppliers who have been engaged in the production of lithium-ion batteries and upstream raw

6 FAQs about [San Salvador lithium battery production and processing]

Which countries are accelerating efforts to localize lithium production?

For instance, while China leads in large-scale production, countries like India are accelerating efforts in local cell manufacturing, and South American nations like Chile, with their lithium reserves, are exploring partnerships to localize production and integrate renewable energy sources.

Which countries are focusing on sustainable battery production?

For example, India is expanding its battery manufacturing capacity with a focus on sustainable processes, while South America, led by countries like Chile, is leveraging its lithium reserves to support a globally integrated supply chain.

What is the future of battery manufacturing?

More compact, multifunctional machines can transform battery production, making it more efficient in terms of space, cost, and scalability. The future of battery manufacturing will see increased integration of space-saving equipment and advanced formation processes that reduce production time and costs.

Why is smart manufacturing important in the battery industry?

The production and assembly of battery electrodes directly impact the performance of these batteries, which necessitates improved production technologies for better results. Smart manufacturing, which integrates machines, objects, instruments, and human workers, is becoming increasingly common in the battery industry.

Are Chinese battery companies expanding their manufacturing in Europe?

Another trend is for Chinese battery companies, such as CATL, to establish and expand their manufacturing in other continents, particularly Europe. 43 Manz AG, GROB-WERKE GmbH & Co. KG, and Dürr Group have entered a strategic partnership to jointly acquire and execute projects for outfitting complete battery manufacturing plants.

Why are Li-ion batteries so popular?

The global demand for Li-ion batteries (LIBs) has been increasing rapidly because of the popularity of electric vehicles (EVs) and energy storage. The transition to EVs drives this surge in demand as part of global efforts to address climate change, with many regions focusing on EVs to reduce greenhouse gas (GHG) emissions.

Update Information

- San Salvador lithium energy storage power production plant

- San Salvador Battery Pack Lithium Battery

- 12v1 3a lithium battery pack production

- Automated production of lithium battery cabinets in Nicosia

- Maldives lithium battery production company

- Production of lithium battery pack types

- Small company cylindrical lithium battery production plant

- San Salvador wall mounted energy storage battery manufacturer

- Nairobi lithium battery pack processing

- Nassau lithium battery processing plant

- Production of lithium battery equipment for energy storage

- Castrie lithium battery pack processing

- Dominic lithium battery pack processing

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.