CloudLi | Intelligent Lithium Battery Solution

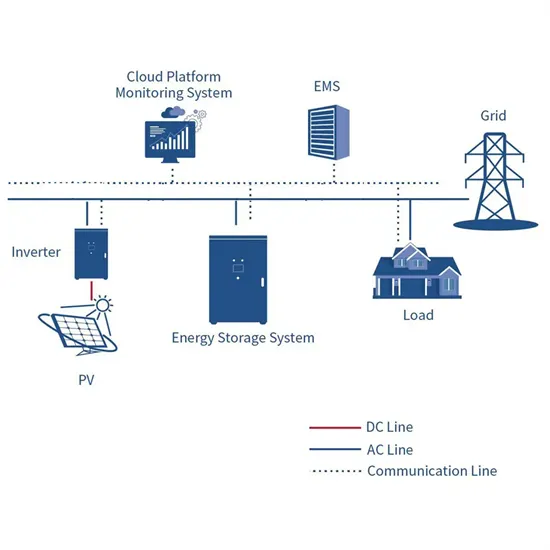

CloudLi integrates power electronics, IoT, and cloud technologies to implement intelligent energy storage in scenarios involving power equipment from Huawei and third parties, unleashing

CloudLi | Intelligent Lithium Battery Solution

Huawei CloudLi Smart Lithium Battery integrates advanced power electronics, IoT, and cloud technologies, offering intelligent energy storage solutions with real-time monitoring and

SmartLi UPS | Lithium battery UPS in Malaysia | Huawei

Feb 11, 2025 · SmartLi Huawei SmartLi is a Huawei-developed battery energy storage system solution that provides backup power for medium- and large-sized data centers and key power

Huawei Batteries | Solar Hybrid Inverters & Power Modules –

Powerland Huawei LUNA 5KWh Battery Module Only Part No: SUN2000-LUNA-5KW-EO Storage Systems - Li-ion Battery Pack Smart String Energy By Luna This is the battery 5KWh module

Automated lithium battery conveying production line

Module Lithium Battery Assembly PACK Conveyor Production Line: A semi-automatic PACK line combining human-machine operation, with a focus on key units such as manual stacking of

PowerPoint 演示文稿

Mar 1, 2024 · LFP is the safest cell of Li-ion battery. The unique active current balance control technology supports the mix use of new and old batteries, which reduces Capex (Capital

Lithium for All | Huawei Digital Power

Huawei''s intelligent lithium battery solutions provide dynamic peak shifting, transforming traditional backup power systems into efficient energy storage solutions that enhance system flexibility

Lithium Batteries: Huawei Power-M

Dec 5, 2023 · Description Additional Battery Module for the - Huawei Isitepower-M 1PH Back-Up Kit 5KW Inverter 5KWh Battery Li-Ion One addtional battery brings total backup battery to 10

Planning of IoT (Internet of Things) Forum 2016

Aug 11, 2020 · provides intelligent battery management functions. Collects statistics on the battery voltage, temperature, SOC, and SOH, and reports the statistics to the SBCU. Detects the

An Approach for Automated Disassembly of

Jul 20, 2022 · A large number of battery pack returns from electric vehicles (EV) is expected for the next years, which requires economically efficient disassembly

ESS-240V12-9AhBPVBA03 Modular Battery Pack Quick Guide

Jan 18, 2019 · Install battery cables at the other negative battery terminal. side and connect the positive battery cable of the battery string to the battery module wiring NOTE terminal. When

Assembly line for battery modules and battery packs

6 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

6 FAQs about [Huawei lithium battery pack module automation]

What are the technical parameters of intelligent battery pack?

Intelligent battery pack finished product handling and packaging system. 3: Technical Parameters: Total production line length: 16 meters. Production capacity: Up to X battery packs per hour (customizable). Precision level: ±0.1mm positioning accuracy. Processing efficiency: 99.5% uptime.

What is a 3 layer battery management system (BMS)?

The three-layer battery management system (BMS) ensures the reliability of lithium batteries. A built-in fire extinguisher is used. Before the BCB switch is turned on, the SmartLi can automatically detect the insulation impedance of the positive and negative battery terminals to PE, ensuring safe startup and operation.

What is a smart lithium battery?

The SmartLi provides lithium battery cell short-circuit detection and alarm functions to ensure the safe operation of lithium batteries. High energy density reduces the footprint compared with lead-acid batteries. The intelligent BMS reduces routine O&M costs.

How many cells are in a battery module?

A battery module has 40 lithium iron phosphate cells (two parallel strings, each consisting of 20 cells connected in series). The built-in BMU manages battery balance, measures common data such as battery voltage and temperature, generates alarms, and implements CAN communication between battery modules. The battery module is normal.

How long does a smartli battery backup take?

The backup time can be 15 minutes, 30 minutes, 1 hour, 2 hours, or 4 hours, depending on the capacity of the SmartLi 2.0 lithium battery cabinet. A maximum of 15 SmartLi 2.0 lithium battery cabinets can be connected in parallel. When multiple cabinets are connected in parallel, only the master cabinet has an LCD.

How many smartli lithium battery cabinets can be connected?

Scenario where SmartLi 3.0 lithium battery cabinets are deployed outside the smart module: One integrated UPS can connect to a maximum of 10 SmartLi 3.0 lithium battery cabinets. When multiple cabinets are connected in parallel, only the master cabinet has an LCD.

Update Information

- Huawei lithium battery module pack

- Huawei Ljubljana lithium battery pack module

- Huawei rohs lithium battery pack

- Which 24v lithium battery pack is better

- Introduction of Gabon Power Lithium Battery Pack

- Spanish 72v lithium battery pack

- Lithium battery pack base project

- 60v80a lithium battery pack

- What is the minimum voltage of the 6-series lithium battery pack in China and Europe

- 8 7 4v lithium battery pack

- Selling lithium battery pack factory

- Lithium battery pack has a string of small capacity

- Huawei Myanmar Energy Storage Lithium Battery

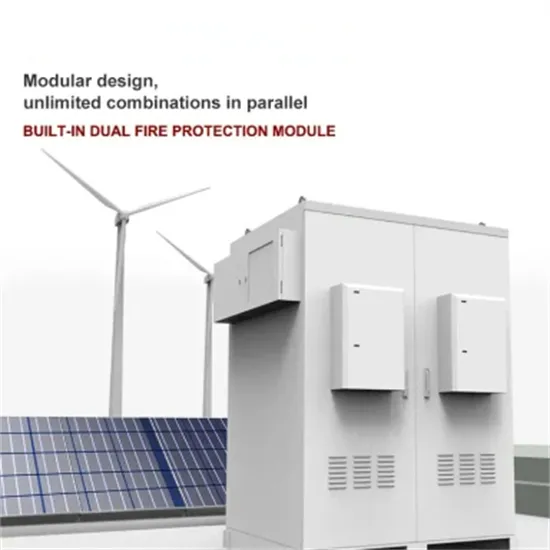

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.