A novel flywheel energy storage system: Based on the barrel

Mar 1, 2022 · The technical requirements and theoretical background of the flywheel energy storage system (FESS) are described in detail in Section 2, and the configuration structure,

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extensively

Optimising flywheel energy storage systems for enhanced

Jun 1, 2025 · Concerns about global warming and the need to reduce carbon emissions have prompted the creation of novel energy recovery systems. Continuous braking results in

Nonlinear dynamic characteristics and stability analysis of energy

Jan 1, 2022 · In this paper, the nonlinear dynamic characteristics and stability of an energy storage flywheel rotor with shape memory alloys (SMA) damper are studied. A new type of

A novel flywheel energy storage system: Based on the barrel

Mar 1, 2022 · In this paper, a novel FESS is proposed form the configuration, material and its structure, and driving motor. The novel FESS uses all metal materials to achieve a lower cost;

Design and Experimental Study of a Toroidal Winding Flywheel Energy

Jan 3, 2025 · In this study, a toroidal winding flywheel energy storage motor is designed for low and medium speed occasions, aiming to meet the challenges of conventional high-speed

A Review of Flywheel Energy Storage System Technologies

Sep 7, 2023 · This article comprehensively reviews the key components of FESSs, including flywheel rotors, motor types, bearing support technologies, and power electronic converter

Design and Analysis of the Multi-layer Sleeve Structure for

Jun 5, 2025 · The flywheel energy storage system (FESS) has been widely applied in transportation and industry fields due to its desirable performance in efficient energy con

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

The Structure Optimization Design of Bearingless Switched

In order to optimize the torque performance of high-speed Bearingless Switched Reluctance Motor (BSRM) for flywheel energy storage and solve the problem of large torque ripple caused

Design, Fabrication, and Test of a 5 kWh Flywheel Energy

Oct 28, 2021 · Introduction A flywheel energy storage system typically works by combining a high-strength, high-momentum rotor with a shaft-mounted motor/generator. This assembly is

飞轮储能系统电机转子散热研究进展

Apr 25, 2023 · 针对MW飞轮储能电机转子散热难题,提出了中空轴内通流冷却的新方案。 关键词: 飞轮储能系统, 电机转子, 散热系统, 空心轴通流冷却, 热管

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy sto

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate th

Rotor Design for High-Speed Flywheel Energy Storage

Jun 14, 2022 · More recently, flywheel systems were developed as true energy storage devices, which are also known as mechanical or electromechanical batteries. A remarkable example of

Multi–physical-field characteristics modeling and structure

Apr 1, 2023 · The research status of ultra-high-speed motor is shown in Fig. 1. NASA and the Pennsylvania State University have developed an ultra-high-speed motor with a maximum

Jet impingement cooling in rotating flywheel energy storage

Jul 1, 2025 · As an innovative energy storage technology, flywheel energy storage systems (FESS) have garnered substantial research interest in recent years, particularly regarding their

Introduction to motors and controllers of flywheel energy storage

Abstract: This paper introduces flywheel energy storage system (FESS) with particular focus on motors and controllers. The paper covers the principle and characteristics of permanent

Design and Analysis of the Multi-layer Sleeve Structure for

Jun 5, 2025 · The flywheel energy storage system (FESS) has been widely applied in transportation and industry fields due to its desirable performance in efficient energy

Design and Research of a New Type of Flywheel Energy Storage

Feb 18, 2025 · The present article proposes a novel design for a zero-flux coil permanent magnet synchronous motor flywheel energy storage system, which exhibits a simple structure with

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

6 FAQs about [Flywheel energy storage motor structure]

What are flywheel energy storage systems?

Using energy storage technology can improve the stability and quality of the power grid. One such technology is flywheel energy storage systems (FESSs). Compared with other energy storage systems, FESSs offer numerous advantages, including a long lifespan, exceptional efficiency, high power density, and minimal environmental impact.

Can axial-type same pole motor be used as a flywheel energy storage system?

Ekaterina Kurbatova proposed a magnetic system for an axial-type same pole motor suitable as both motor/generator in combination with the integrated design of the motor/generator, which can be utilized in conjunction with the flywheel energy storage system.

What is a compact and highly efficient flywheel energy storage system?

Abstract: This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss caused by the flux of permanent magnetic machines. A novel compact magnetic bearing is proposed to eliminate the friction loss during high-speed operation.

What is a 7 ring flywheel energy storage system?

In 1999 , the University of Texas at Austin developed a 7-ring interference assembled composite material flywheel energy storage system and provided a stress distribution calculation method for the flywheel energy storage system.

How much energy can a flywheel store?

The small energy storage composite flywheel of American company Powerthu can operate at 53000 rpm and store 0.53 kWh of energy . The superconducting flywheel energy storage system developed by the Japan Railway Technology Research Institute has a rotational speed of 6000 rpm and a single unit energy storage capacity of 100 kW·h.

How to optimize the structure of composite flywheel energy storage system?

Arvin et al. used simulated annealing method to optimize the structure of composite flywheel and optimized the energy storage density of flywheel energy storage system by changing the number of flywheel layers.

Update Information

- Flywheel energy storage motor system

- Flywheel energy storage traction motor

- Flywheel energy storage battery structure

- What does flywheel energy storage built-in motor mean

- Flywheel energy storage synchronous motor price

- Original capacity of flywheel energy storage

- Flywheel energy storage is

- Advantages and disadvantages of flywheel energy storage mode

- F1 flywheel energy storage

- Superconducting flywheel energy storage and flywheel rotor

- Lima Flywheel Energy Storage

- Huawei s flywheel energy storage business model

- Flywheel energy storage photovoltaic battery for communication base station

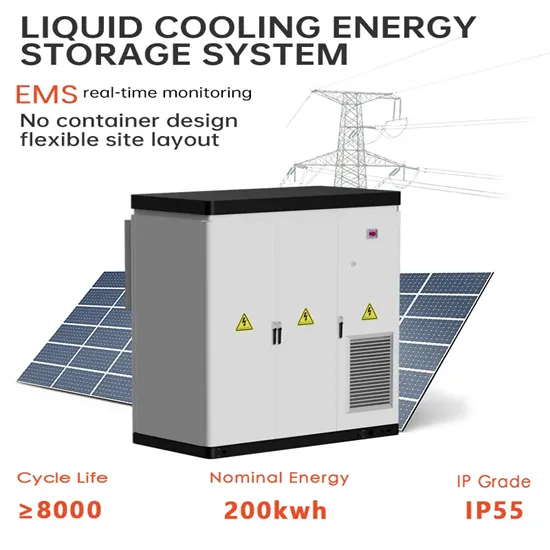

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

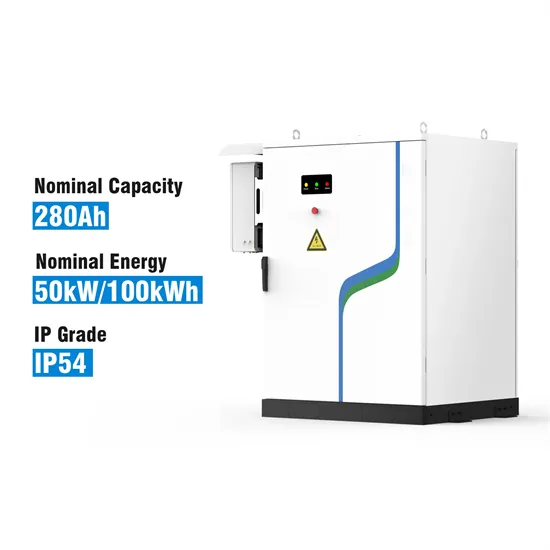

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.