Overview of Flywheel Systems for Renewable Energy

Jul 12, 2024 · storage systems (FESS) are summarized, showing the potential of axial-flux permanent-magnet (AFPM) machines in such applications. Design examples of high-speed

Development of a High Specific Energy Flywheel Module,

Aug 6, 2020 · a rapidly spinning wheel - with 50 times the Storage capacity of a lead-acid battery As the flywheel is discharged and spun down, the stored rotational energy is transferred back

Design, Fabrication, and Test of a 5 kWh Flywheel Energy

Oct 28, 2021 · A flywheel energy storage system typically works by combining a high-strength, high-momentum rotor with a shaft-mounted motor/generator. This assembly is contained

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate th

Design, modeling, and validation of a 0.5 kWh flywheel energy storage

Nov 1, 2024 · The flywheel energy storage system (FESS) has excellent power capacity and high conversion efficiency. It could be used as a mechanical battery in the uninterruptible power

Design and Research of a New Type of Flywheel Energy Storage System

Feb 18, 2025 · This article proposes a novel flywheel energy storage system incorporating permanent magnets, an electric motor, and a zero-flux coil. The permanent magnet is utilized

Introduction to motors and controllers of flywheel energy storage systems

Abstract: This paper introduces flywheel energy storage system (FESS) with particular focus on motors and controllers. The paper covers the principle and characteristics of permanent

Sensorless fault-tolerant control strategy of flywheel energy storage

Flywheel energy storage systems (FESS) are crucial for efficient energy storage in power systems. However, the sensorless control strategy for flywheel motors can experience speed

Optimising flywheel energy storage systems for enhanced

Jun 1, 2025 · Wang et al. (2022) developed a control strategy for High-Speed Motor-Flywheel Energy Storage Systems (HSM-FESS), with simulation models confirming the effectiveness of

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

Design and Analysis of a Unique Energy Storage Flywheel System

Apr 1, 2015 · A typical flywheel system is comprised of an energy storage rotor, a motor-generator system, bearings, power electronics, controls, and a containment housing. Conventional outer

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

The controls of motors in flywheel energy storage system

Jun 11, 2014 · During startup stage of short-term acceleration system such as continuous shock test, high power induction motor draws dramatically high current in a short time, which would

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extensively

6 FAQs about [Flywheel energy storage motor system]

How does a flywheel energy storage system work?

Based on the aforementioned research, this paper proposes a novel electric suspension flywheel energy storage system equipped with zero flux coils and permanent magnets. The newly developed flywheel energy storage system operates at high speeds with self-stability without requiring active control.

What is a compact and highly efficient flywheel energy storage system?

Abstract: This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss caused by the flux of permanent magnetic machines. A novel compact magnetic bearing is proposed to eliminate the friction loss during high-speed operation.

How does a flywheel work?

The power system delivers electrical energy to the flywheel device. Discharge: The process converts the mechanical energy consumed by the rotation of the flywheel into electrical energy and transmits it out, the drive motor operates as a generator, and the speed of the flywheel will decrease accordingly.

Can flywheel energy storage improve wind power quality?

FESS has been integrated with various renewable energy power generation designs. Gabriel Cimuca et al. proposed the use of flywheel energy storage systems to improve the power quality of wind power generation. The control effects of direct torque control (DTC) and flux-oriented control (FOC) were compared.

What is a flywheel energy storage system (fess)?

The flywheel energy storage system (FESS) cooperates with clean energy power generation to form “new energy + energy storage”, which will occupy an important position among new energy storage methods.

Are flywheel energy storages commercially available?

Flywheel energy storages are commercially available (TRL 9) but have not yet experienced large-scale commercialisation due to their cost disadvantages in comparison with battery storages (higher investment, lower energy density). Another challenge is the comparably high standby loss in FESS caused by the magnetic drag of the motor-generator.

Update Information

- Flywheel energy storage motor structure

- Flywheel energy storage synchronous motor price

- Flywheel energy storage battery structure

- MW-class flywheel energy storage project connected to the grid

- Flywheel energy storage in Alexandria Egypt

- Flywheel energy storage photovoltaic battery for communication base station

- Construction of flywheel energy storage project for communication base station in Tajikistan

- Sales price of flywheel energy storage cabinet for communication base station

- Key flywheel energy storage companies

- Monrovia communication base station flywheel energy storage distribution

- Structure of flywheel energy storage

- Windhoek 5G communication base station flywheel energy storage application

- Flywheel system energy storage device composition

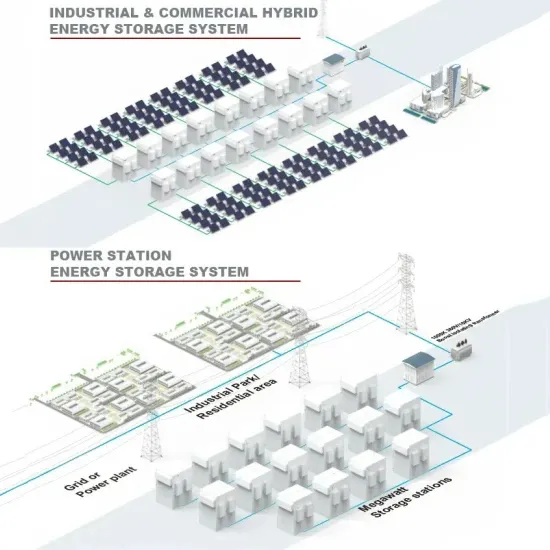

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.