F1 Flywheel Energy Storage: The Secret Behind Racing''s

Ever wondered how Formula 1 cars recover energy at 200 mph without carrying bulky batteries? Let''s face it – F1 flywheel energy storage isn''t exactly dinner table conversation, but this

The Status and Future of Flywheel Energy Storage,Joule

May 2, 2019 · Currently a Professor of Energy Systems at City University of London and Royal Academy of Engineering Enterprise Fellow, he is researching low-cost, sustainable flywheel

The Status and Future of Flywheel Energy Storage

Jun 19, 2019 · The core element of a flywheel consists of a rotating mass, typically axisymmetric, which stores rotary kinetic energy E according to (Equation 1) E = 1 2 I ω 2 [J], where E is the

The Status and Future of Flywheel Energy Storage

Jun 26, 2019 · Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully sustainable yet low cost.

Kinetic Energy Recovery System (KERS).

May 6, 2020 · The flywheel increases maximum acceleration and nets 10% pedal energy savings during a ride where speeds are between 12.5 and 15 mph. Index Terms2 KERS, Regenerative

Enhancing vehicular performance with flywheel energy storage

Dec 10, 2024 · Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing performance in vehicular

High-Speed Kinetic Energy Storage System Development

Apr 8, 2025 · Flywheel energy storage systems (FESSs) can reach much higher speeds with the development of technology. This is possible with the development of composite materials. In

Why did the flywheel hybrid system never catch on for

Feb 14, 2021 · In 2009, F1 teams were allowed to use hybrid systems for the first time. The Williams F1 team chose to develop one that used a flywheel instead of a chemical battery or

WHY DO F1 RACE CARS NEED A FLYWHEEL ENERGY STORAGE

What is a flywheel energy storage system? Flywheel energy storage systems (FESS) are a great way to store and use energy. They work by spinning a wheel really fast to store energy, and

WHY DO F1 RACE CARS NEED A FLYWHEEL ENERGY STORAGE

Flywheel energy storage is a promising technology for energy storage with several advantages over other energy storage technologies. Flywheels are efficient, have a longer lifespan, and

F1 Racing Energy Storage Devices: Powering Speed and

Why Energy Storage Matters in F1 (Hint: It''s Not Just About Speed) Ever wondered how Formula 1 cars manage to hit 230 mph while sipping energy like a frugal espresso drinker? The secret

Williams F1 and Kinetic Traction Systems Reach

Sep 1, 2011 · Williams F1 and Kinetic Traction Systems Reach Agreement to Advance Composite Flywheel Energy Storage Technology for Rail and Grid Applications September 01, 2011 09:00

Williams F1 and Kinetic Traction Systems partner to advance

Sep 1, 2011 · Williams Grand Prix Engineering Limited (Williams F1) and Kinetic Traction Systems, Inc. (KTSi) have signed a long-term cooperation Agreement to advance and promote

Design and Optimization of a Flywheel Based Kinetic

May 10, 2024 · Georgia Institute of Technology, Atlanta, GA 30332 Kinetic Energy Recovery System (KERS) has been used with great effect in Formula 1 racing. The extreme cost

Advancing sustainable mobility: Integrating flywheel kinetic energy

May 6, 2025 · This paper explores the feasibility of integrating Flywheel KERS with high-efficiency H 2 ICEs to create a fully mechanical energy management system, addressing the limitations

The Status and Future of Flywheel Energy Storage

Jun 26, 2019 · Outline Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully

Williams Hybrid Power Flywheel

Sep 19, 2012 · Williams Hybrid Power is developing electromechanical flywheel energy storage systems for a range of applications such as hybrid buses, trams, and endurance racing cars. Find out how this innovative technology works and its benefits

6 FAQs about [F1 flywheel energy storage]

What are flywheel energy storage systems (fess)?

Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing performance in vehicular applications. This review comprehensively examines recent literature on FESS, focusing on energy recovery technologies, integration with drivetrain systems, and environmental impacts.

Why do F1 race cars need a flywheel energy storage system?

Flybrid Systems was among the primary suppliers of such innovative flywheel energy storage solutions for F1 race cars . Flywheels in motorsport undergo several charge/discharge cycles per minute, thus standby losses are not a huge concern. Conventional driving schemes, on the other hand, necessitate a greater level of standby efficiency.

Can flywheel energy storage systems be used in vehicles?

Provided insights into the current applications of FESS in vehicles, highlighting their role in sustainable transportation. Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing performance in vehicular applications.

How important is a flywheel size & depth of charge in F1?

Results indicated that for a particular vehicle, an optimal flywheel size and depth of charge are needed to maintain a balance between high transmission efficiency and low system mass. FESS have been utilised in F1 as a temporary energy storage device since the rules were revised in 2009.

How does a flywheel work?

Electrical energy is transferred to rotating kinetic energy by a novel magnetic material (sometimes a magnetic powder) embedded within the flywheel. The more energy applied, the faster it spins. (NB: this is different to the mechanical flywheel hybrid system that Nissan attempted unsuccessfully to develop for its 2015 Le Mans racer.)

When did flywheel technology start in F1?

The declaration by the Federation Internationale de l'Automobile (FIA) in 2006, focusing on the recovery and reuse of kinetic energy in Formula One (F1) racing cars, was a pivotal moment for flywheel technology. The 2009 F1 season saw the introduction of KERS, including flywheel-based systems.

Update Information

- Sana flywheel energy storage device

- Egypt Communication Base Station Flywheel Energy Storage Construction Company

- Flywheel energy storage photovoltaic battery for communication base station

- Flywheel energy storage battery structure

- Lima Flywheel Energy Storage

- Afghanistan communication base station flywheel energy storage

- Sales price of flywheel energy storage cabinet for communication base station

- What are the components of a flywheel energy storage device

- Monrovia communication base station flywheel energy storage distribution

- Structure of flywheel energy storage

- Lebanon communication base station flywheel energy storage equipment

- Windhoek 5G communication base station flywheel energy storage application

- How to develop flywheel energy storage for communication base stations

Solar Storage Container Market Growth

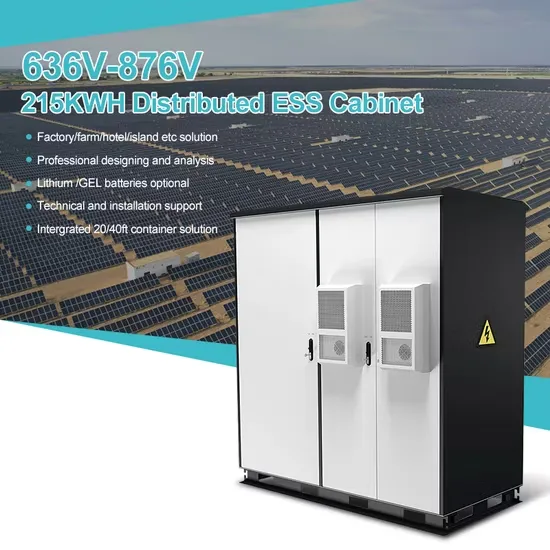

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.