Traction Power Wayside Energy Storage and Recovery

Feb 25, 2022 · Flywheel Energy Storage Motor-driven, high-speed rotating mass contained in a vacuum Up to 16,000 rpm (Beacon Power) 10,000 to 20,000 rpm (VYCON) Up to 45,000 rpm

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate th

Control strategy for high speed flywheel energy storage

Nov 1, 2022 · Control strategy for high speed flywheel energy storage system based on voltage threshold of DC1500 V transit transportation traction grid

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

Flywheel technology generates energy efficiencies for metros

May 14, 2025 · With recent advances in energy storage technology, urban rail operators are harnessing the ability to reduce traction power consumption. Venky Krishnan director of

Clean Power Concept: Recovering, Restoring and Recycling Energy

Sep 4, 2023 · Benefits of Flywheel Energy Storage Kinetic Traction Systems (KTSi) GTR flywheels use a fully integrated, permanent magnet, DC motor/generator capturing, storing and

RPC Coordinated Control Strategy with Battery and Flywheel Energy Storage

Mar 12, 2025 · The coordinated control strategy of battery and flywheel energy storage device is proposed for the real-time data of railroad locomotive traction load. By means of the new

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

飞轮储能技术研究五十年评述

May 31, 2018 · A single flywheel stored energy of 0.5~130 kW·h in charging or discharging with power of 0.3~3000 kW. The frontier technologies include new materials of flywheel rotor, super

2 MW 130 kWh Flywheel Energy Storage System

Jun 19, 2017 · During deceleration, traction motors regenerate electric energy and dissipate the power in a dynamic braking resistor grid. The ALPS system replaces the diesel electric

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Simulation of Flywheel Energy Storage System Controls

Aug 6, 2020 · the flywheel energy storage model has been presented. This model incor-porates an electro-mechanical machine model, which is able to simulate energy transfer to and from

A new approach to analysis and simulation of flywheel energy storage

Aug 10, 2022 · To power electronic gadgets, hybrid energy storage systems have emerged as a worldwide option during the last several years. Many of the benefits of energy storage systems

doi: 10.1007/978-3-658-35342-1_9

Aug 31, 2023 · natural frequency behavior of the entire flywheel energy storage system, three representa-tive scenarios were analytically recalculated on the basis of the linear single mass

Simulation on application of flywheel energy storage system

Nov 29, 2022 · Considering the voltage fluctuation of the DC traction network in STDS caused by subway braking, this paper establishes the flywheel energy storage system (FESS) to

Flywheel energy storage controlled by model predictive

Jul 1, 2023 · Secondly, a mathematical model of the flywheel energy storage system applied in the model predictive control algorithm is proposed, and the model predictive control algorithm

Research on Control Strategy of Flywheel Energy Storage

Sep 24, 2024 · Theoretically, 30%–40% of the traction energy required by locomotives can be compensated by the recovered braking energy, which has a substantial energy-saving

Enhancing vehicular performance with flywheel energy storage

Dec 10, 2024 · Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing performance in vehicular

Clean Power Concept: Recovering, Restoring and Recycling Energy

Sep 4, 2023 · Kinetic Traction Systems (KTSi) GTR flywheels use a fully integrated, permanent magnet, DC motor/generator capturing, storing and regenerating energy. By capturing energy,

2 MW 130 kWh Flywheel Energy Storage System

Jun 19, 2017 · Abstract The Center for Electromechanics has developed and is currently testing a 2 MW, 130 kWh (480 MJ) flywheel energy storage system (FESS) designed as a load leveling

Flywheel energy storage systems: Review and simulation for

Dec 1, 2012 · Flywheel energy storage systems (FESSs) store mechanical energy in a rotating flywheel that convert into electrical energy by means of an electrical machine and vice versa

Overview of Flywheel Systems for Renewable Energy

Jan 9, 2025 · in three modes of operation, i.e., charging, standby and discharging, and perform the energy conversion, as illustrated in Fig. 2. During the charging mode, the machine works

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

Application of flywheel energy storage for heavy haul

Nov 1, 2015 · The initial stage studies a possible configuration of the flywheel energy storage system by detailed modelling of the proposed intelligent traction and energy control system.

Flywheel in an all-electric propulsion system

Apr 7, 2014 · The flywheel is inserted in between the main energy storage (assumed to be a battery) and the traction motor in an electric vehicle. This system has been evaluated by

6 FAQs about [Flywheel energy storage traction motor]

How does a flywheel energy storage system work?

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical energy is thus converted to kinetic energy for storage. For discharging, the motor acts as a generator, braking the rotor to produce electricity.

What is a compact and highly efficient flywheel energy storage system?

Abstract: This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss caused by the flux of permanent magnetic machines. A novel compact magnetic bearing is proposed to eliminate the friction loss during high-speed operation.

What are flywheel energy storage systems (fess)?

Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing performance in vehicular applications. This review comprehensively examines recent literature on FESS, focusing on energy recovery technologies, integration with drivetrain systems, and environmental impacts.

Can flywheel energy storage systems be used in vehicles?

Provided insights into the current applications of FESS in vehicles, highlighting their role in sustainable transportation. Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing performance in vehicular applications.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

What is a beacon power flywheel?

The Beacon Power Flywheel , which includes a composite rotor and an electric machine, is designed for frequency regulation. Fig. 1 has been produced to illustrate the flywheel energy storage system, including its sub-components and the related technologies.

Update Information

- Flywheel energy storage motor system

- Flywheel energy storage motor structure

- What does flywheel energy storage built-in motor mean

- 5g communication base station flywheel energy storage setting requirements

- Egypt Communication Base Station Flywheel Energy Storage Construction Company

- Lima Flywheel Energy Storage

- Construction of flywheel energy storage project for communication base station in Tajikistan

- What is flywheel energy storage produced with

- Sana flywheel energy storage device

- Sales price of flywheel energy storage cabinet for communication base station

- Flywheel hybrid energy storage

- Key flywheel energy storage companies

- Structure of flywheel energy storage

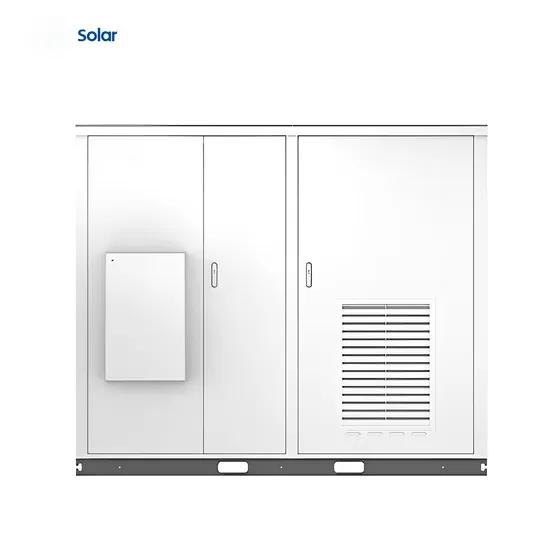

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.