An Overview of the R&D of Flywheel Energy Storage

Nov 9, 2024 · Today, the overall technical level of China''s flywheel energy storage is no longer lagging behind that of Western advanced countries that started FES R&D in the 1970s. The

Flywheel energy storage—An upswing technology for energy

May 1, 2007 · Flywheel energy storage (FES) can have energy fed in the rotational mass of a flywheel, store it as kinetic energy, and release out upon demand. It is a significant and

Geometry Modification of Flywheels and its Effect on

From such applications as pottery wheels to steam engines, flywheels have been used to store mechanical energy. Currently, in the ever expanding world of green energy development,

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

A cross-entropy-based synergy method for capacity

Feb 1, 2025 · Energy storage systems, coupled with power sources, are applied as an important means of frequency regulation support for large-scale grid connection of new energy. Flywheel

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy storage (FESS),

Technology: Flywheel Energy Storage

Oct 30, 2024 · Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to

How much energy is suitable for flywheel energy storage

Jun 26, 2024 · With ongoing enhancements in materials science and engineering methodologies, the efficiency, capacity, and applicability of flywheel systems are likely to continue improving.

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

On Specific Energy Capacity of Flywheel Energy Storage

Feb 25, 2023 · Abstract The paper introduces basic methods of computational investigation for specific energy capacity of flywheel energy storage. In addition to the traditional estimation of

Flywheel Energy Storage: Alternative to Battery

Oct 5, 2024 · As the energy grid evolves, storage solutions that can efficiently balance the generation and demand of renewable energy sources are critical.

Flywheel energy storage

Oct 28, 2015 · Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy. When energy is

"Offshore Application of the Flywheel Energy Storage"

Mar 12, 2024 · FINISHED ity of FESS (Flywheel Energy Storage System) has been fully developed. Several load scenarios have been t S is to be implemented into RTS (Real Time

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Flywheels store rotational kinetic energy in the form of a spinning cylinder or disc, then use this stored kinetic energy to regenerate electricity at a later time. The amount of

Flywheel Energy Storage Study

May 4, 2020 · The core of this particular FES System technology involves the development of a lower-cost steel flywheel, which will reduce the first cost of the energy storage device, while

Analysis and design of the capacity and efficiency of a flywheel energy

Stress analyses indicated that both the 3-layer flywheel at a speed of 9000 r/min and the 4-layer flywheel at a speed of 15000 r/min would meet the structural strength requirements with an

Flywheel Systems for Utility Scale Energy Storage

Apr 6, 2022 · An early unit from the project, an M25 with a power capacity of 6.25kW and 25kWh energy storage capacity flywheel, was temporarily sent to a site in Subic Bay Philippines by

Design and Application of Flywheel–Lithium Battery Composite Energy

Feb 12, 2024 · For different types of electric vehicles, improving the efficiency of on-board energy utilization to extend the range of vehicle is essential. Aiming at the efficiency reduction of

An Overview of the R&D of Flywheel Energy Storage

Nov 5, 2024 · A steel alloy flywheel with an energy storage capacity of 125 kWh and a composite flywheel with an energy storage capacity of 10 kWh have been successfully developed.

What is the energy storage capacity density of a flywheel?

May 21, 2024 · The energy storage capacity density of flywheels presents a remarkable opportunity for various sectors, particularly in renewable energy integration and grid

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

An Overview of the R&D of Flywheel Energy Storage

Nov 9, 2024 · A steel alloy flywheel with an energy storage capacity of 125 kWh and a composite flywheel with an energy storage capacity of 10 kWh have been successfully developed.

What is the capacity of flywheel energy storage?

Aug 7, 2024 · 1. The capacity of flywheel energy storage is determined by multiple factors, including energy density, duration of energy release, and the design of

Composite flywheel material design for high-speed energy storage

Jun 1, 2016 · Lamina and laminate mechanical properties of materials suitable for flywheel high-speed energy storage were investigated. Low density, low modulus and

6 FAQs about [Original capacity of flywheel energy storage]

What is the energy storage capacity of a flywheel?

A steel alloy flywheel with an energy storage capacity of 125 kWh and a composite flywheel with an energy storage capacity of 10 kWh have been successfully developed. Permanent magnet (PM) motors with power of 250–1000 kW were designed, manufactured, and tested in many FES assemblies.

Can flywheel energy storage be commercially viable?

This project explored flywheel energy storage R&D to reach commercial viability for utility scale energy storage. This required advancing the design, manufacturing capability, system cost, storage capacity, efficiency, reliability, safety, and system level operation of flywheel energy storage technology.

When did flywheel energy storage start?

The theoretical exploration of flywheel energy storage (FES) started in the 1980s in China. The experimental FES system and its components, such as the flywheel, motor/generator, bearing, and power electronic devices, were researched around thirty years ago.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Can flywheel energy storage improve wind power quality?

FESS has been integrated with various renewable energy power generation designs. Gabriel Cimuca et al. proposed the use of flywheel energy storage systems to improve the power quality of wind power generation. The control effects of direct torque control (DTC) and flux-oriented control (FOC) were compared.

What is the main technology of Flywheel energy storage system?

The main power circuit technology is mature, and the main research is the conversion control algorithm. China has successfully developed MW-class motor converters for flywheel energy storage systems. 4. FES System

Update Information

- How is flywheel energy storage in large communication base stations

- Flywheel energy storage can

- Flywheel material in flywheel energy storage

- How many communication base station flywheel energy storage companies are there in China

- What is the flywheel energy storage mode

- Lightspeed flywheel energy storage

- Huawei Dublin Flywheel Energy Storage Project

- Construction process of flywheel energy storage for foreign communication base stations

- Flywheel energy storage vehicle power supply method

- Flywheel energy storage design

- North Asia Flywheel Energy Storage Power Generation Company

- San Marino Flywheel Energy Storage

- Flywheel Energy Storage Project in Ethiopia

Solar Storage Container Market Growth

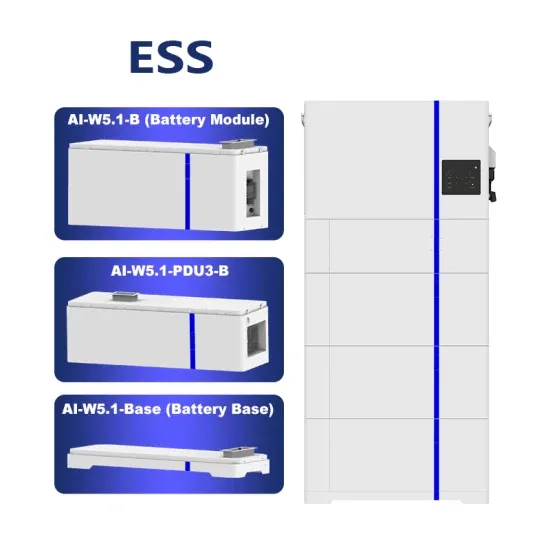

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.