Superconducting energy storage flywheel—An attractive technology

Feb 4, 2010 · Flywheel energy storage (FES) can have energy fed in the rotational mass of a flywheel, store it as kinetic energy, and release out upon demand. The superconducting

Development and test of a superconducting high-speed

Nov 21, 2018 · Superconducting is Better Advantages for Flywheels The use of superconducting bearings in a flywheel has the following advantages Rotor hub

Comparison of Heavy-Load Superconducting Maglev

Dec 24, 2024 · As a novel form of energy storage, large-capacity flywheels offer a promising solution for supporting the efficient operation of new energy grid connection and advanced

Suspension-Type of Flywheel Energy Storage System Using

Jun 19, 2022 · Werfel et al. [6] proposed a radial-type SMB for a superconducting flywheel energy storage system composed of a permanent magnet rotor with a diameter of 𝜙 ϕ 200 mm, an air

Comparison of Heavy-Load Superconducting Maglev

Dec 24, 2024 · As a novel form of energy storage, large-capacity flywheels offer a promising solution for supporting the efficient operation of new energy grid connection and

Theoretical calculation and analysis of electromagnetic

Nov 15, 2024 · This article presents a high-temperature superconducting flywheel energy storage system with zero-flux coils. This system features a straightforward structure, substantial

Energy storage flywheel electromagnetic field

Flywheel energy storage systems: A critical review on technologies, applications, and future prospects This structure is a combination of the rotor''''s energy storage parts and

Test equipment for a flywheel energy storage system using a

Mar 17, 2016 · The superconducting magnetic bearing can revolve the flywheel rotor smoothly because it can support the flywheel rotor without any contact and any mechanical friction, but

Superconducting Energy Storage Flywheel —An

Aug 25, 2017 · The superconducting energy storage flywheel comprising of mag-netic and superconducting bearings is fit for energy storage on account of its high efficiency, long cycle

Case study on flywheel energy storage systems: LPTN-based

Jun 1, 2025 · This study established a lumped parameter thermal network model for vertical flywheel energy storage systems, considering three critical gaps in conventional thermal

Progress of superconducting bearing technologies for flywheel energy

Apr 15, 2003 · We report present status of NEDO project on "Superconducting bearing technologies for flywheel energy storage systems". We fabricated a superconducting magnetic

Peer Review Oct 2005

Mar 27, 2012 · Objective: • build and deliver flywheel energy storage systems utilizing high temperature superconducting (HTS) bearings tailored for uninterruptible power systems and

Progress of superconducting bearing technologies for flywheel energy

Apr 15, 2003 · We confirmed that both pre-loading and excess cooling methods are effective for suppressing gradual fall of rotor due to flux creep. We designed a 10 kW h class flywheel

Suspension-Type of Flywheel Energy Storage System

Nov 9, 2023 · The experimental results discuss some important characteristics of the superconducting flywheel energy storage system, whose rotor is suspended by the

Optimizing superconducting magnetic bearings of HTS flywheel

Jun 1, 2024 · The potential applications such as flywheel energy storage systems (FESS) and high-speed rotating machines, have attracted extensive research interest [2], [3], [4]. Boeing

SUPERCONDUCTING FLYWHEEL MODEL FOR ENERGY

Oct 13, 2005 · In this paper we explore the complexity and diversity of the flywheels'' dynamics by means of the real-physics computer model of a universal mechanical rotor. We study the

Design of flywheel energy storage device with high specific energy

Jun 27, 2025 · The flywheel energy storage system is a way to meet the high-power energy storage and energy/power conversion needs. Moreover, the flywheel can effectively assist the

Performance evaluation of a superconducting flywheel energy storage

Jun 15, 2022 · In this paper, a novel high-temperature superconducting flywheel energy storage system (SFESS) is proposed. The SFESS adopts both a superconducting magnetic bearing

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy storage (FESS),

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Index Terms—flywheel energy storage system, energy storage, superconducting magnetic bearings, permanent magnetic bearings, power system quality, power system cost

Flywheels Turn Superconducting to Reinvigorate

Apr 7, 2021 · A flywheel battery stores electric energy by converting it into kinetic energy using a motor to spin a rotor. The motor also works as a generator; the

6 FAQs about [Superconducting flywheel energy storage and flywheel rotor]

What is superconducting energy storage Flywheel?

The superconducting energy storage flywheel comprising of mag-netic and superconducting bearings is fit for energy storage on account of its high efficiency, long cycle life, wide operating temperature range and so on.

How many types of high-temperature superconducting energy storage flywheels are there?

Accordingly, there are two main types of high-temperature superconducting energy storage flywheels, and if a system comprising both the thrust bearing and the radial bearing will have the characteristics of both types of bearings.

Which flywheel is suitable for energy storage?

The flywheel comprising of magnetic and supercon-ducting bearings is fit for energy storage. Supercon-ducting energy storage flywheel can be used in space for energy storage, attitude control for satellites.

What is a flywheel energy storage system?

1. Introduction The flywheel energy storage system [1, 2] is a highly promising technology for efficient energy storage, comprising a flywheel rotor , bearings [, , ], vacuum technologies, and motor [, , , , , , ].

Can high temperature superconductors improve flywheel performance?

While past applications of the flywheel have used conventional mechanical bearings that had relatively high losses due to friction, the development of magnetic bearings constructed using High Temperature Superconductors (HTSC) has greatly decreased the losses due to friction and increased efficiency immensely.

Is a new suspension support method needed for flywheel energy storage systems?

Therefore, a new suspension support method is urgently needed for flywheel energy storage systems to solve these problems. Xiaojun Li presents a novel combination 5-DOF AMB (C5AMB) designed for a shaft-less, hub-less, high-strength steel energy storage flywheel (SHFES), which achieves doubled energy density compared to prior technologies.

Update Information

- Superconducting energy storage flywheel

- Price of superconducting energy storage system

- Sales price of flywheel energy storage cabinet for communication base station

- Does the flywheel energy storage fiber of the communication base station have a battery

- What is the flywheel energy storage of Iceland s communication base stations like

- Flywheel energy storage in Alexandria Egypt

- Flywheel energy storage photovoltaic battery for communication base station

- Huawei s flywheel energy storage business model

- Flywheel energy storage battery structure

- Construction of flywheel energy storage project for communication base station in Tajikistan

- Lima Flywheel Energy Storage

- Afghanistan communication base station flywheel energy storage

- Sana flywheel energy storage device

Solar Storage Container Market Growth

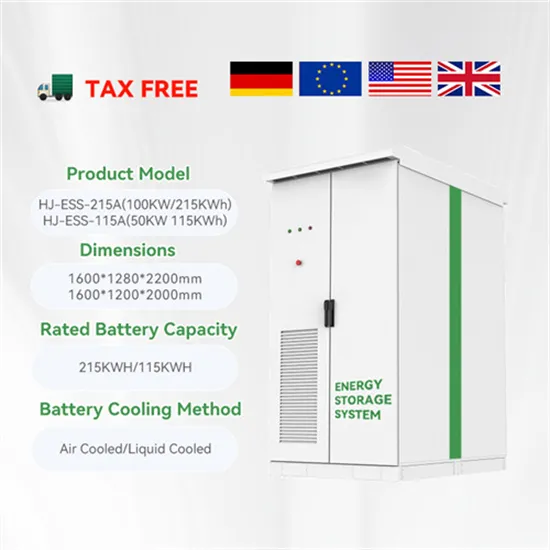

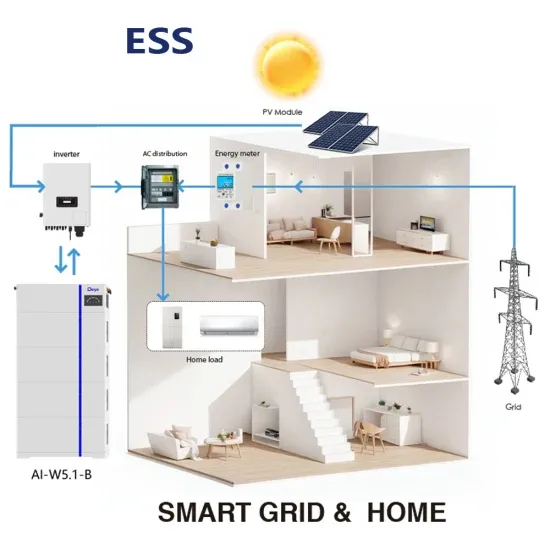

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.