Methods and precautions for lithium battery

Jan 29, 2024 · Li-ion battery is a high energy density battery which is widely used in mobile electronic devices, electric vehicles and energy storage systems,

How to Assemble Lithium Battery Cells into Battery Pack

Apr 14, 2025 · The process of assembling lithium battery cells into complete battery pack is called battery PACK. It involves integrating key components such as battery cells, protection board,

Beginner-Friendly Tips for Assembling Lithium Battery Packs

May 7, 2025 · Effective planning lays the foundation for a reliable lithium battery pack. You should start by defining the application requirements, such as voltage, capacity, and size constraints.

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

Jun 15, 2025 · Here are the key benefits of assembling your own lithium battery pack instead of buying a pre-made one: You can fully customize the battery''s voltage, capacity, discharge rate

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · The production of a lithium battery pack is a multifaceted process, involving several crucial steps to guarantee the final product''s quality and

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

Jun 15, 2025 · Assembling your own custom battery pack allows you to tailor a power solution to your specific needs, whether for an electric vehicle, solar storage system, robotics project or

How Are Lithium Battery Packs Assembled?

Aug 18, 2025 · By following the key steps involved in lithium battery pack assembly, including cell selection and testing, cell arrangement and connection, BMS integration, and final assembly

What to pay attention to when assembling the battery pack

What Are The Issues To Pay Attention To When Assembling Mar 20, 2015. What Are The Issues To Pay Attention To When Assembling Lithium-ion Battery Packs. Matters needing

Understanding the Battery Cell Assembly Process

Nov 11, 2023 · The Three Main Stages of Battery Cell Production The production process of a lithium-ion battery cell consists of three critical stages: electrode

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Diferent shapes of the lithium-ion cell Nomenclature of lithium-ion cell/battery Overview of Li-ion battery packs Assembling Process Detailed flowchart for Li-ion battery pack

KEY POINTS IN THE LITHIUM BATTERY MODULE PACK

This article by Paladugu Chandrasekhar (CEO, Futurelite Batteries) discusses the tests involved in assembling Lithium-ion cells into modules and battery packs. Machine needed – Individual

The points to note when assembling lithium batteries are

A Closer Look at the Manufacturing Process of Lithium Ion Batteries A Closer Look at the Manufacturing Process of Lithium Ion Batteries Introduction Lithium-ion batteries have become

10 Essential Safety Rules For Lithium Battery Pack Design

May 8, 2025 · In high-energy environments, even minor design oversights can lead to serious incidents such as fires or explosions. To help engineers and development teams enhance the

Lítium akkumulátorok ponthegesztéshez kockázat nélkül

Jun 27, 2025 · Spot welding is a crucial aspect of battery technology, particularly when learning how to spot weld lithium batteries for assembling reliable battery packs. This precise technique

Beginner-Friendly Tips for Assembling Lithium Battery Packs

May 7, 2025 · Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Fire safety in Lithium-ion battery pack

Jun 13, 2021 · There is a high fire risk related to the storage, processing and use of Lithium-ion batteries. In this article, guest author Neeraj Kumar Singal talks

Key points for assembling lithium iron phosphate batteries

Our range of products is designed to meet the diverse needs of base station energy storage. From high-capacity lithium-ion batteries to advanced energy management systems, each

Understanding the Lithium-Ion Battery Manufacturing Process

Aug 5, 2025 · Assembling lithium-ion cells is a crucial step in the manufacture of lithium-ion batteries. Without proper assembly, the efficiency, safety, and lifespan of the battery can be

Summary of key points of lithium battery assembly technology

Key Points in the Lithium Battery Module PACK Manufacturing The production of lithium battery modules, also known as Battery Packs, involves a meticulous and multi-step

Key Points of Lithium Battery PACK Manufacturing Process

Jun 27, 2024 · Curious about how lithium batterypacks are made? Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to

6 FAQs about [Key points for assembling lithium battery packs]

Why is quality control important in battery pack assembly?

Quality control is paramount in battery pack assembly to prevent defects and ensure safety. Key measures include: Visual Inspections: Checking for physical defects like damaged cells or faulty wiring. Functional Testing: Verifying electrical properties such as voltage, capacity, and charging cycles.

Why is battery pack assembly important?

The significance of the battery pack assembly process lies in its direct impact on the performance and safety of the final product. A well-assembled battery pack ensures optimal energy storage, efficient power delivery, and long-term durability.

What is battery pack assembly process?

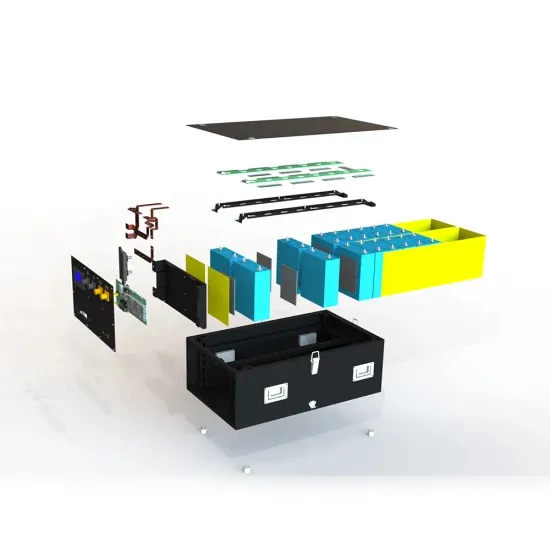

Battery Pack Assembly Process Component Preparation: High-quality battery cells, BMS, wiring, and casings are inspected and prepared for assembly. Cell Assembly: Battery cells are arranged in series or parallel configurations to achieve the required voltage and capacity.

What is lithium ion battery assembly?

Lithium-Ion Battery Assembly: Involves stacking layers of anodes, cathodes, and separators. Assembly techniques include winding for cylindrical cells and stacking for prismatic cells. Requires careful handling of liquid electrolytes during assembly. Lithium Polymer Battery Assembly:

How do you assemble a battery pack?

Assembling a battery pack involves several critical steps to ensure its performance and safety: The first step involves gathering and inspecting all necessary components, such as battery cells, the Battery Management System (BMS), wiring, connectors, and casings. This ensures that only high-quality, defect-free parts are used.

What are the components of an EV battery pack?

An EV battery pack comprises several key elements: Cells: The basic energy storage units, commonly cylindrical, prismatic, or pouch cells. Modules: Groups of cells arranged in series or parallel to achieve the desired voltage and capacity.

Update Information

- Do lithium battery packs need a box

- Can we bring lithium battery packs to Nauru

- Lithium battery packs are assembled in Tskhinvali

- Can lithium battery packs be connected in series again

- 13 lithium battery packs have different voltages

- Three 12v lithium battery packs in series 36v

- Chisinau makes lithium battery packs

- 8 groups of lithium iron phosphate battery packs connected in series

- Is there a difference in the power of lithium battery packs

- Can Indonesian lithium battery packs be connected

- Ankara produces lithium battery packs

- EK Tool Lithium Battery

- Buenos Aires Power Tools Lithium Battery

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.