Ultimate Power: Lithium-Ion Batteries In Series

Apr 4, 2024 · For instance, if you see 12.6 V pack voltage, it''s exceptionally likely to be a 3s?p pack (4.2*3), and if it''s 14.4 V, it''s likely a 4s?p pack (3.6*4).

Can You Power a 36V Golf Cart with Three 12V Batteries?

Feb 28, 2025 · Yes, you can power a 36V golf cart using three 12V batteries connected in series. This configuration sums the voltages of each battery (12V + 12V + 12V) to provide the required

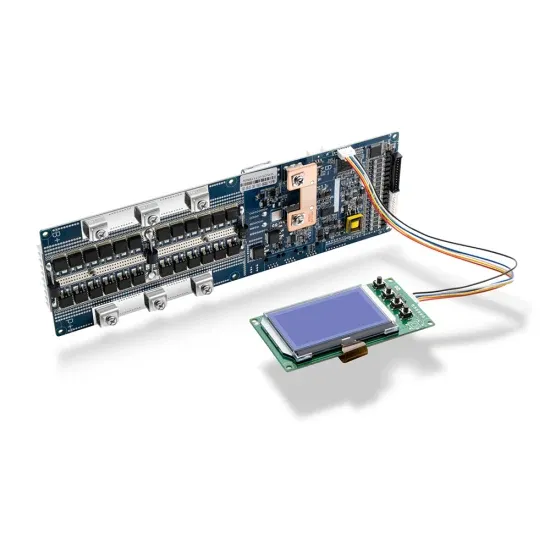

Dual Pro Battery Optimization System for Three 12V Batteries In Series

Dual Pro Battery Optimization System 12v 3 Battery in Series 36v SystemModel: BOS12V3Approved for use with Wet Cell, AGM and Lithium Ion batteriesDesigned for 12V

Lithium 36v battery vs 3 12v battery configuration

Apr 16, 2024 · I have read several posts on this page about people who are running 3 12v lithium trolling motor batteries along with a Power Pole charge system and having difficulties with

Three 12V Lithium Batteries vs. a Single 36V Lithium Battery

Nov 28, 2023 · Using three 12V lithium batteries in a series connection creates a 36V battery system, providing increased power output, longer runtime, and lighter weight compared to

Can You Use 3 12V Batteries in a 36V Golf Cart?

Aug 14, 2024 · Yes, you can use three 12V batteries connected in series to create a 36V system suitable for a 36V golf cart. It is crucial that the batteries match in type, age, and capacity to

How Many Lithium Batteries Do I Need for a 36V Golf Cart?

Aug 8, 2024 · To power a 36V golf cart with lithium batteries, you typically need three 12V lithium batteries connected in series or a single 36V lithium battery if available. The choice depends

Battery Wiring Simplified: Series vs Parallel for

Apr 28, 2025 · Wire three of them in series — positive to negative, negative to positive — and boom, you''ve got 36V. It''s like linking train cars: each battery

Why a 36V Lithium Battery Is Better Than Three 12V Batteries

Apr 25, 2025 · Discover why a 36V lithium battery from Lithium Battery Power outperforms traditional 12V setups. Enjoy longer lifespan, lighter weight, and superior trolling motor power

一个36V锂铁电池或三个12V锂铁电池? 利弊

When an application called for 36 volts in the past, connecting three 12V batteries in a series was the optimum solution. 然而, given the availability of 36V batteries, you could be considering

Which Battery Setup Is Better: 36V 100Ah Lithium or Three 12V

Apr 13, 2025 · Short Answer: A 36V 100Ah lithium battery offers higher energy density, longer lifespan, and simpler installation than three 12V 100Ah lead-acid batteries. However, the 12V

How to Properly Connect 12V Batteries in Series

Sep 4, 2024 · Connecting batteries in series to achieve a higher voltage is a fundamental technique for optimizing the power system of your golf cart. If you

How Do You Charge 3 12V Lithium Batteries in Series?

Dec 16, 2023 · Charging three 12V lithium batteries in series involves connecting them to a charger designed for the combined voltage of the series configuration. When connected in

Series vs Parallel Battery Wiring: The Ultimate 2025 Guide

Apr 18, 2025 · Learn the key differences between series and parallel battery wiring. Discover how to optimize voltage, capacity, and performance for your energy needs in 2025.

6 FAQs about [Three 12v lithium battery packs in series 36v]

Where can I buy a 36V lithium battery?

Shop the range of 36V lithium batteries at Ryobi. Our 36V batteries are compatible with the MAXPOWER range of Ryobi tools. Find your ideal 36v battery here. Browse our full range of 36V MAX POWER batteries. Visit our website for full details.

How to wire 3 12V batteries for 36V?

In this post, I am going to tell you how to wire 3 12v batteries for 36v in detail. Install all 3 of your 12V batteries together, side by side. Make sure the negative terminal of one is connected to the positive terminal of another. When you look at it from this perspective, you can see that all three are upside down, or negative end up.

What is a 12V lithium ion battery pack?

A 12V lithium ion battery pack is a battery pack made up of three or four lithium batteries connected in series and several lithium batteries connected in parallel. This configuration allows the capacity of a 12V lithium battery to be customized.

What is the difference between a 12V battery and a 36V battery?

Much longer lasting. Lighter and more compact. Three 12V lithium batteries or a 36V lithium battery will weigh 70% less than a similar setups of other battery types. Amperage remains consistent even when below 50% battery life. Discharge rate when not in use is only 2% per month (The rate is 30% for lead acid batteries).

Can I swap a 36 volt battery for 3 12 volt batteries?

You can swap a single 36 volt 50AH battery for three 12V 50 amp hour batteries wired in series. But is that the right way to go? It depends on what you need to power, the type of battery you’re using, and personal preference. First, let’s take a look at how battery type might affect your choice. What type of 36 volt battery are you using?

What is a 36 volt battery pack?

A 36 volt battery pack with lithium-ion technology delivers concentrated energy for demanding applications in trade and industry. These battery packs power tools that are in no way inferior to their mains-powered counterparts.

Update Information

- 8 groups of lithium iron phosphate battery packs connected in series

- Can lithium battery packs be connected in series again

- How many Prague lithium battery packs are connected in series at 72 volts

- Lithium battery 30ah 12v system solar panel 100w

- Advantages of Greek lithium battery packs

- Lithium battery packs for sale in Latvia

- Moroni lithium battery pack 12v selection

- How many strings of 24 volt lithium battery packs are needed

- Caracas 12v lithium battery pack

- Do lithium battery packs need a box

- Telecom site lithium battery pack 12v battery cabinet

- Lithium battery packs charge and discharge quickly

- Tool lithium battery series connection

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.