Multiphysics simulation optimization framework for lithium-ion battery

Jan 15, 2022 · Integrating simulation-based design optimization in battery development process expands the possibilities for novel design exploration. This study presents a dual-stage

Indonesia Lithium-ion Battery Packs Market (2025-2031)

Historical Data and Forecast of Indonesia Lithium-ion Battery Packs Market Revenues & Volume By Lithium Nickel Manganese Cobalt for the Period 2021- 2031 Historical Data and Forecast of

Lithium-ion battery packs | VARTA AG

Aug 18, 2025 · The Lithium-Ion batteries are modular and expandable and therefore can be adjusted for your application in industries like logistics, agriculture and others. Customers are

Indonesia: CATL in US$6 billion battery integration project

Jul 7, 2025 · A subsidiary of CATL and local partners have begun construction on a battery manufacturing complex in West Java, Indonesia. The world''s biggest lithium-ion (Li-ion)

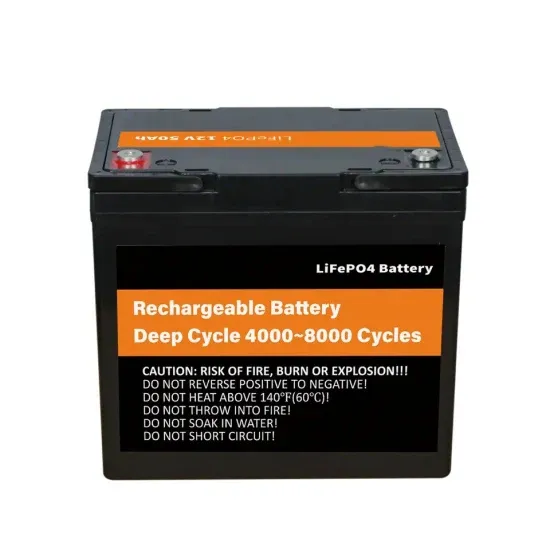

Ultimate Guide to Selecting 4S, 13S, 14.8V, and 16S BMS:

2 days ago · DIY Lithium Battery Packs: Series and Parallel Techniques for 4S to 16S BMS What Are Series and Parallel Connections? Series connections increase voltage (e.g., 4S = 14.8V),

Charging Li-ion batteries in parallel

Aug 26, 2014 · This way, you even get packs with serially connected cells (eg. 3s1p) where the cell voltages stay closely matched over the lifetime of the pack (several years) - without

Seizing Indonesia''s Position in the Global Supply

Jan 30, 2024 · Under this context, critical minerals needed by the EV battery industry are more critical for Indonesia and ASEAN. Lithium, nickel, cobalt,

Influence of connection impedance on the performance of

Feb 15, 2024 · The insights gained from this research offer valuable guidance for optimizing the design and performance of parallel-connected lithium-ion battery modules, ultimately

Battery Innovation System of Indonesia

Jun 12, 2024 · As one of the fastest growing economies and the world''s largest producer of nickel (a key component in lithium-ion batteries), Indonesia has huge potential to become one of the

Electric Vehicle Battery Cell Factory in Indonesia

Strategic steps need to be taken to support the development of the national electric vehicle industry. These steps can be taken by encouraging the development of battery technology.

Policy Brief Accelerating Battery Supply Chain for RE and

Jul 9, 2025 · minimum battery production capacity of approximately 36.8 GWh to meet its EV targets. Currently, the country has only 10 GWh of NMC battery cell capacity (from PT HLI

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · Strings, Parallel Cells, and Parallel Strings Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is

China''s REPT Battero to Establish Battery Manufacturing

Jan 16, 2025 · China''s REPT Battero has revealed plans to build a lithium-ion battery plant in Indonesia, targeting 8 GWh of annual production capacity in the first phase.Hong Kong-listed

Australia, Indonesia can team up on lithium supply chain

Oct 13, 2022 · Indonesia can process Australian lithium —a critical component for electric vehicle batteries— to be later exported to other markets such as the US, according to former

Cylindrical cells Archives — Large Battery

With over two decades of lithium battery development, Nagy teljesítmény egy megbízható cylindrical cell manufacturer ügyfelek kiszolgálása automotive, energy storage, consumer

Multi-battery Packs | Li-Ion & LiPoly Batteries

Jul 29, 2012 · If you want to take your project portable you''ll need a battery pack! For beginners, we suggest alkaline batteries, such as the venerable AA or 9V

Optimal fast charging strategy for series-parallel configured lithium

Jan 1, 2025 · The limited charging performance of lithium-ion battery (LIB) packs has hindered the widespread adoption of electric vehicles (EVs), due to the complex arrangement of numerous

First EV battery plant launched in Indonesia, the

Jul 16, 2024 · It will manufacture batteries for Hyundai''s electric cars; the Indonesian-made battery is anticipated to power 50,000 Kona Electric SUVs.

Management of imbalances in parallel-connected lithium-ion battery packs

Aug 1, 2019 · Uneven electrical current distribution in a parallel-connected lithium-ion battery pack can result in different degradation rates and overcurrent issues in the cells. Understanding the

6 FAQs about [Can Indonesian lithium battery packs be connected ]

Does Indonesia have a battery supply chain?

In this article, we at Fitch Solutions assess Indonesia’s potential along the battery supply chain. Indonesia’s battery supply chain is still in its nascent stage, but the country is well placed to benefit from the global EV adoption race in the coming years through its natural resource endowment (nickel, copper) and government initiatives.

Why do EV batteries need to be imported from Indonesia?

However, the scarcity of lithium in Indonesia, as the critical mineral for battery EVs, causing a dependency on the import is inevitable. Most of EV batteries, such as NMC battery, contains a cathode made up of lithium, nickel, manganese, and cobalt.

Why is Indonesia a leader in the lithium battery industry?

In 2024, Indonesia stands at the forefront of the rapidly evolving lithium battery industry, catalyzed by its significant reserves of raw materials essential for battery production and a growing focus on renewable energy sources. As Southeast Asia's largest economy, Indonesia has strategically positioned itself as a

What are EV batteries made of in Indonesia?

Most of EV batteries, such as NMC battery, contains a cathode made up of lithium, nickel, manganese, and cobalt. Indonesia needs 70,000 of lithium hydroxide annually, yet still imports the mineral from China, Australia, and Chile. The market dynamics of critical minerals also affect the battery supply chain in Indonesia.

Should Indonesia invest in the electric battery industry?

Indonesia's ambitious targets in the electric battery industry offer a prime opportunity for strategic investments and partnerships.

Why should you choose PT Indonesia Battery Corporation?

The key advantage of PT Indonesia Battery Corporation lies in its integrated approach to manufacturing. Utilizing Indonesia’s abundant nickel resources, the company maintains control over the entire production process, from raw material extraction to the final battery product.

Update Information

- How many Prague lithium battery packs are connected in series at 72 volts

- Can lithium battery packs be connected in series again

- Lithium battery packs charge and discharge quickly

- Advantages of Greek lithium battery packs

- Lithium battery packs can be stacked

- Three 12v lithium battery packs in series 36v

- Key points for assembling lithium battery packs

- Is there a difference in the power of lithium battery packs

- How many strings of 24 volt lithium battery packs are needed

- South Tarawa Energy Storage Lithium Battery Components

- Assembly process of square lithium battery

- Base station lithium iron phosphate battery communication base station

- Zhengzhi lithium battery smart inverter

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.