Lithium Battery Voltage Standards Overview | EB BLOG

Oct 22, 2024 · Additionally, voltage balancing treatments for battery packs and setting up comprehensive detection and monitoring mechanisms are vital measures to ensure that

Battery Pack Cell Voltage Difference and

Jan 18, 2021 · For battery packs, the voltage difference between individual cells is one of the main indicators of consistency. The smaller the voltage difference,

On-line equalization for lithium-ion battery packs based on

Feb 1, 2014 · In the series of two papers, we discover that dissipative cell equalization (DCE) using dissipative resistances is a feasible on-line equalization method for battery packs in EVs.

Why do battery packs have different charging voltages

Different battery chemistries have different rated voltages; for example, Li-ion cells have a rated voltage of 3.7V, while alkaline cells have a rated voltage of about 1.5V.

On-line equalization for lithium-ion battery packs based on

Nov 19, 2015 · On-line equalization for lithium-ion battery packs based on charging cell voltages Part 1. Equalization based on remaining charging capacity estimation - 豆丁网

Lithium LiFePO4 Battery Voltage Charts For 12V,

Aug 19, 2025 · Cbattery = Ik × t Since we have LiFePO4 batteries with different voltages (12V, 24V, 48V, 3.2V), we have prepared all 4 battery voltage charts

Simulation of voltage imbalance in large lithium-ion battery packs

Dec 1, 2020 · In order to reduce load currents and consequently ohmic losses within battery packs and charging infrastructure, system voltage is usually increased by connecting cells in series.

Fault diagnosis and quantitative analysis of micro-short

Aug 15, 2018 · Micro-short circuit (MSC) of a lithium-ion battery cell is a potential safety hazard for battery packs. How to identify the cell with MSC in the laten

Voltage difference between modules

Feb 13, 2023 · Hi there, I have 10 battery modules in a pack. Each module has 51 volts. I would like to know how much voltage difference are allowed between to modules? I mean more than

Lithium-Ion Information Guide | Houston, Texas USA

Lithium-Ion Information Guide - Technology ProfileBattery packs built to customer specifications using Lithium-Ion and Lithium-Polymer cells have been Designed and Developed at SWE for

Understanding Lithium Battery Voltage

Mar 27, 2025 · Understanding lithium battery voltage is crucial for selecting the ideal power source for your devices. Lithium battery voltage influences its energy capacity, charging

The Fundamentals of Battery/Module Pack Test

Oct 17, 2023 · The Importance of Battery Module and Pack Testing The battery market is growing rapidly due to the acceleration of electrification in the automotive, aerospace and energy

State of Charge Imbalance Classification of Lithium-ion

Oct 2, 2022 · Abstract—Lithium-ion battery strings are important modules in battery packs. Due to cell variation, strings may have im-balanced state of charge levels, reducing pack capacity and

Can I parallel multiple Lithium Battery Packs?

May 27, 2025 · One of the most critical factors is to ensure that the battery packs you want to parallel have matching specifications. This includes voltage, capacity, chemistry, and state of

mixing different battery types/voltages

Aug 26, 2009 · My understanding is that if you use multiple batteries in series, they should have the same amp hours. I think I know why but can someone provide clarification? But what about

Why do lithium batteries made of different materials have different

Different types of lithium batteries have varying nominal voltages, mainly influenced by the materials used for the anode, cathode, and electrolyte. For instance, LiFePO4 batteries have a

Lithium-ion battery pack equalization based on charging

Feb 1, 2020 · Lithium-ion battery pack capacity directly determines the driving range and dynamic ability of electric vehicles (EVs). However, inconsistency issues occur and decrease the pack

Can lithium battery packs be assembled with different voltages

Estimation of State of Charge for Lithium-Ion EV Battery Packs According to the application, a lot of cells are often connected in series to create a battery line with the necessary voltage

6 FAQs about [13 lithium battery packs have different voltages]

How many volts is a lithium polymer battery?

Single lithium polymer (Li-Po) cells typically have a nominal voltage of 3.7 volts. When the voltage of this type of cell is charged to 4.2 volts, it is considered fully charged. During the battery discharge process, when the voltage drops to 3.27 volts, the battery is considered fully discharged.

How does a lithium ion battery charge?

During charging, lithium-ion batteries exhibit distinct voltage characteristics that reflect their electrochemical processes. The charging cycle typically follows a constant current-constant voltage (CC-CV) protocol. Initially, the battery voltage rises steadily as current flows into the cell.

What is the difference of inconsistency for lithium-ion battery pack equalization?

The difference of inconsistency for lithium-ion battery pack equalization is determined based on the uniform charging cell voltage curves hypothesis. Stability of the sampling voltage interval and convergence of equalization are analyzed experimentally.

What are the different types of lithium batteries?

Different types of lithium batteries, like lithium cobalt oxide, lithium iron phosphate, and lithium polymer, though all part of the lithium family, have vastly different voltage curves and electrochemical characteristics.

What is the relationship between voltage and soc in lithium polymer batteries?

During the charging and discharging process of lithium polymer (Li-Po) batteries, the relationship between voltage and SOC (State of Charge) exhibits clear nonlinear characteristics. Especially when the battery is approaching full charge or discharge, the voltage changes more rapidly.

What if there is a voltage difference in a battery pack?

Therefore, you should pay attention to the brand from which you are purchasing your batteries. If there is a gap in the voltage of the battery pack, you can correct it with additional equipment, such as with a BMS, balance charging, etc. Stay tuned for Part 2 of voltage difference: How to prevent voltage difference.

Update Information

- Two different lithium battery packs connected in parallel

- Different types of lithium battery packs

- Can lithium battery packs be connected in series again

- Professional cylindrical lithium battery of different models

- How many strings of 24 volt lithium battery packs are needed

- 36 lithium battery packs have a difference of 1v

- Three 12v lithium battery packs in series 36v

- Can we bring lithium battery packs to Nauru

- Lithium battery packs are assembled in Tskhinvali

- Key points for assembling lithium battery packs

- Do lithium battery packs need a box

- The role of solar lithium battery packs in Mozambique

- Is there a difference in the power of lithium battery packs

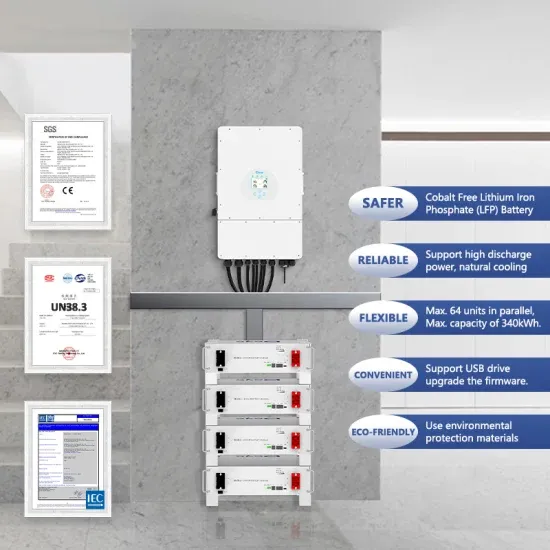

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.