PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · The publication "Production process of a lithium-ion battery cell" provides a comprehensive process overview of the production of different battery cell formats from

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · , this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several

Automated assembly of Li-ion vehicle batteries: A feasibility study

Jan 1, 2020 · Electric Vehicles (EVs) with rechargeable Lithium-Ion batteries (Li-ion) are at the forefront of the global trend for lower-emission transportation and decarbonisation. Capable

Investigation of series-parallel connections of multi-module batteries

Dec 19, 2014 · Large-format Lithium-ion battery packs consist of the series and parallel connection of elemental cells, usually assembled into modules. The required voltage an

Fault diagnosis and abnormality detection of lithium-ion battery packs

Jan 15, 2021 · Abstract Lithium-ion battery packs are widely deployed as power sources in transportation electrification solutions. To ensure safe and reliable operation of battery packs,

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Among various energy storage technologies, lithium-ion battery packs have emerged as the preferred choice due to their high energy density, long cycle life, and

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · The lithium battery pack plays a crucial role in the manufacture of lithium-ion batteries, involving packaging, encapsulation, and assembly. This

LiFePO4 Battery Packs for Solar PV Energy Storage

Dec 6, 2024 · 🔋 LiFePO4 Battery Packs for Solar PV Energy Storage 🔋 From start to finish: ️ Sourced with original factory cells ️ Assembled into battery packs with full testing and aging

A review of state-of-health estimation for lithium-ion battery packs

May 15, 2025 · With the rapid advancement of lithium-ion battery technology, the estimation of the state of health (SOH) of lithium-ion battery packs plays a crucial role in enhancing the safety

Optimal fast charging strategy for series-parallel configured lithium

Jan 1, 2025 · The limited charging performance of lithium-ion battery (LIB) packs has hindered the widespread adoption of electric vehicles (EVs), due to the complex arrangement of numerous

An experimental study on thermal management of lithium ion battery

Apr 1, 2018 · The ternary material and prismatic lithium ion battery constituted a sandwich structure which presented much better performance of heat dissipation and temperature

Beginner-Friendly Tips for Assembling Lithium Battery Packs

May 7, 2025 · Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Battery pack design and assembly processes

Mar 26, 2024 · One example of a battery pack is the Tesla Model S battery pack. The Tesla Model S battery pack is a lithium-ion battery pack that has a capacity of 85 kWh. The battery

Tskhinvali Energy Storage Project Bidding: What You Need

Let''s cut to the chase: the Tskhinvali energy storage project bidding isn''t just another infrastructure tender. Think of it as the energy industry''s version of the World Cup – minus the

Hyundai localises over 1,200 components and EV

Jan 21, 2025 · The carmaker is also sourcing locally-assembled battery-packs for the new Creta Electric. The company also showcased its indigenisation efforts

Assembled lithium battery packs in China

Lithium batteries in China China produced more than 15 billion units of lithium-ion batteries in 2019, which accounts for 73% of the world''''s 316 gigawatt-hours capacity. [1] China is a

6 FAQs about [Lithium battery packs are assembled in Tskhinvali]

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

Can Li-ion battery assembly be used in a niche automotive supply chain?

This paper details a feasibility study for Li-Ion battery assembly, developed for a traditional automotive supplier of niche production systems in order to enable them to enter the emerging lower carbon OEM supply chains.

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the possible transferability of competencies from the production of lithium-ion battery cells is illuminated. 2ndedition ISBN 978-3-947920-29-7 Ed. PEM of RWTH Aachen University & VDMA

What type of battery is used in automotive battery assembly packs?

Figure 1: Automotive battery assembly packs, Lee et al. 2.3 Cell Assembly Historically, battery cells have used cylindrical designs. This design was used in mainstream market from alkaline battery cells to Nickel-Metal Hydrite (NiMH) battery cells.

Are Li-ion batteries the future of electric vehicles?

Electric Vehicles (EVs) with rechargeable Lithium-Ion batteries (Li-ion) are at the forefront of the global trend for lower-emission transportation and decarbonisation. Capable suppliers of Li-Ion battery assembly systems are essential for enabling automotive OEMs to scale up their Li-ion EV production to expected volumes.

Update Information

- Advantages of Greek lithium battery packs

- The role of solar lithium battery packs in Mozambique

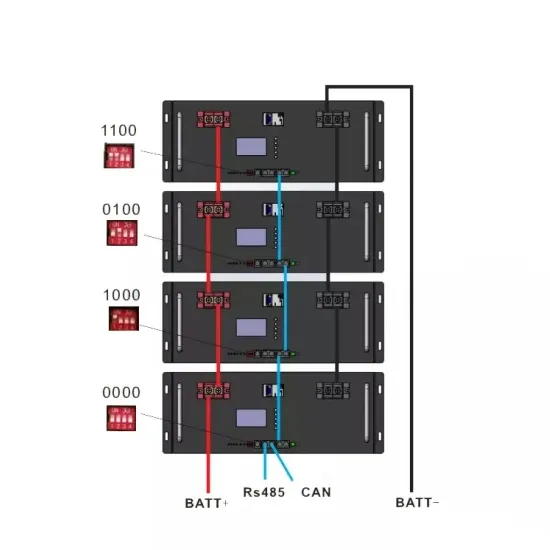

- Three 12v lithium battery packs in series 36v

- 36 lithium battery packs have a difference of 1v

- Can lithium battery packs be connected in series again

- Lithium battery packs can be stacked

- Key points for assembling lithium battery packs

- 8 groups of lithium iron phosphate battery packs connected in series

- Ankara produces lithium battery packs

- Tskhinvali lithium battery energy storage power station

- Lithium battery packs for sale in Latvia

- 13 lithium battery packs have different voltages

- Guyana Energy Storage Low Temperature Lithium Battery Factory

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.