Designing a SPWM Controlled High Voltage (HV) Three

May 12, 2023 · Abstract – There were wide range of the inverting models have been designed in past. SPWM controlled inverters are extensively used for high voltage (HV) renewable energy

MATHEMATICAL MODELING AND ADVANCED

May 7, 2025 · This thesis explores the core advantages of grid-forming inverters comparing to conventional inverters, develops mathematical models for voltage and frequency control, and

Efficient single-phase full-bridge soft-switching inverter

Feb 22, 2021 · A MOSFET is often applied as the switch in medium and small power single-phase full-bridge inverters. In order to achieve efficient operation at a high switching frequency, a

Designing a SPWM Controlled High Voltage (HV) Three

May 12, 2023 · act – There were wide range of the inverting models have been designed in past. SPWM controlled inverters are extensively used for high vol age (HV) renewable energy

Infineon high voltage Inverter Application Presentation

May 25, 2025 · Infineon high voltage Inverter Application Presentation Traction Inverter trends Semiconductors contribute to improved energy efficiency, but also to size and weight

Grid-Forming Inverter Modeling and Real-World

Model Specification of a Droop-based Grid-Forming Inverter (REGFM_A1) The model includes a voltage source representation, P-f and Q-V droop controls, P/Q limiting controls, and a

HV-IGBT Module for High-Performance Inverter Design

Aug 16, 2025 · To meet growing demands for energy-efficient and reliable inverter systems in traction applications, Mitsubishi Electric has introduced the XB-Series high-voltage IGBT

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · The three-phase inverter uses insulated gate bipolar transistor (IGBT) switches which have advantages of high input impedance as the gate is insulated, has a rapid response

6 FAQs about [High voltage inverter model]

Who develops high voltage inverter systems for electric vehicles?

The vehicle manufactures and automotive tier 1 suppliers develop inverter systems for electric vehicles. Discussions were held with their design and research teams during direct meetings to understand future developments. Through these discussions, along with our own research, there are some clear high voltage inverter trends in the EV market. 3.

How can a high voltage inverter improve EV performance?

A better approach is to increase efficiency and decrease weight which extends the range of the EV and potentially reduces vehicle cost and running expenses. A significant contributor to achieving this is the inclusion of enhanced control, high voltage inverter modules in the vehicle. * Corresponding author.

What are the advantages of grid-forming inverters?

This thesis explores the core advantages of grid-forming inverters comparing to conventional inverters, develops mathematical models for voltage and frequency control, and proposes advanced control strategies to handle various disturbances and intermittent power sources.

What are grid-connected inverters?

Grid-connected inverters are mainly divided into GFLIs and GFMIs. GFLIs rely on a stable voltage and frequency provided by the external grid as a reference, synchronising with the grid voltage through techniques such as phase-locked loops (PLLs) (Zhu, D. et al., 2020).

How is the mathematical model of an inverter organized?

The mathematical model of the inverter can be organized initially in the abc three-phase stationary coordinate system. Since the variables controlled by the closed loop are , , , , , their equations are listed and organised in the form of matrices for easy observation and calculation.

What is a V/F inverter?

Usually, the inverter with V/f control will act as the main inverter in the system to provide voltage and frequency support to the local loads, so it is mostly used in off-grid or islanding mode. However, there are limitations in parallel connection of multiple machines as it is more suitable for single or off-grid systems.

Update Information

- Price of high voltage inverter

- Working function of high voltage inverter

- High voltage grid-connected inverter communication method

- EK inverter genuine high voltage

- Household high voltage off-grid inverter

- The role of high voltage three-phase inverter

- Processing high voltage inverter

- High voltage inverter sm

- 12v inverter voltage high

- Photovoltaic high voltage inverter

- High voltage inverter specifications

- EK High Voltage Inverter

- Wide voltage and high power inverter

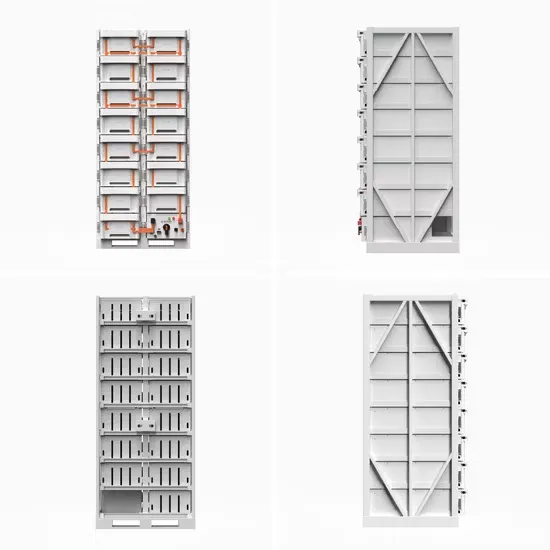

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.