Deye 20Kw 3 Phase High Voltage Inverter

Deye 3 Phase High Voltage Inverter - 20KW, offering 100% unbalanced output on each phase. Perfect for retrofitting existing solar systems, it supports both on-grid and off-grid operations

High Voltage Energy Storage Inverters: Why They Matter in

Oct 1, 2024 · High voltage energy storage inverters are devices that convert the direct current (DC) produced by renewable energy sources into the alternating current (AC) used to power

How to prevent battery drain caused by inverter

Nov 27, 2024 · The inverter likely has an idle power consumption around 18W. Adding an AC charger would allow for float charging the battery to keep it at

A high voltage battery for a three-phase solar

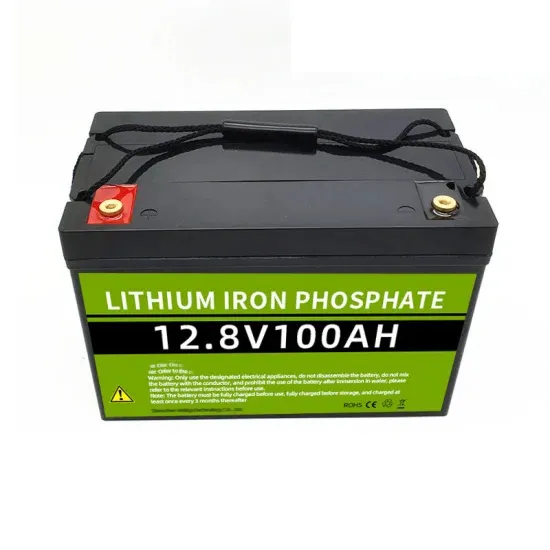

Oct 5, 2023 · A high voltage LiFePO4 battery that can work with a three-phase solar hybrid inverter is a battery that has a high voltage of at 150V to 409V and

In Stock Deye High Voltage 50kW Three Phase Hybrid Inverter

Key Features * High Charging/Discharging Current: Supports a maximum charging and discharging current of 100A, which ensures flexibility in managing energy storage needs. *

From 1000V to 1500V: A Comparison of High and Low Voltage

May 21, 2025 · Through From 1000V to 1500V: A Comparison of High and Low Voltage Energy Storage Inverters news, you can learn more about the real practical applications and

Simplifying Power Conversion in High-Voltage Systems

Nov 9, 2023 · To further minimize switching losses, wide band-gap FETs need an appropriate gate driver capable of rapidly charging and discharging the gate capacitance, since traditional

High Efficiency Solar Deye Hybrid Inverter 20kw Three Phase High

1. High Charging/Discharging Efficiency: * The Deye SUN series inverters boast a maximum charging/discharging current of 50A,allowing for rapid and efficient energy storage and

Solar powered on-board charging system utilizing coupled inductor high

Jul 1, 2025 · The BHGC converter is designed to control the charging and discharging operations in LEVs. The developed BHGC aims to minimize ripples in the charging and discharging

Research and Simulation of a T-Type Three-Level Inverter

Aug 11, 2024 · This paper investigates the issue of neutral-point voltage imbalance in the high-voltage DC-link capacitors of T-type three-level inverters. The analysis begins with a detailed

Hybrid Inverter for Low Voltage Battery: A New Way to

Dec 16, 2024 · 1. Introduction to the Hybrid Inverter The hybrid inverter for low voltage battery is a sophisticated power conversion device that integrates both charging and discharging

Three Phase Hybrid Inverter

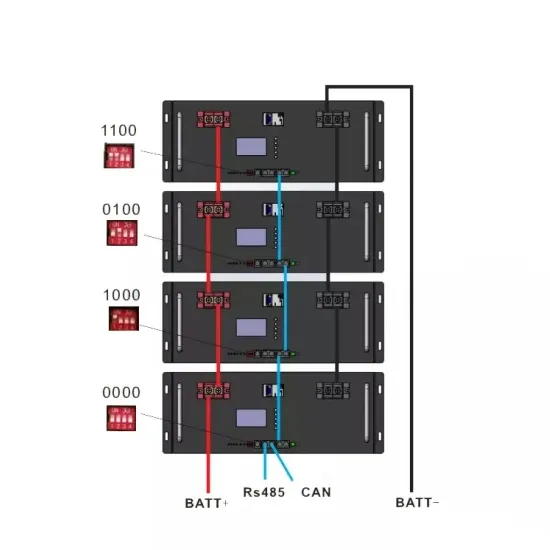

Apr 5, 2024 · Parallel operation is currently being tested for up to ten inverters. The prerequisite for parallel operation is that only Deye high-voltage inverters with the same power and Deye

How to Reduce the Power Resistor for DC-Link

Aug 16, 2024 · The DC-Link capacitor is a part of every traction inverter and is positioned in parallel with the high-voltage battery and the power stage (see Figure 1). The DC-Link

How to Fix Inverter Battery

Apr 5, 2025 · Recharging: If the battery voltage is low, charge the battery using the inverter''s built-in charger or an external charger. Set the charger to the correct voltage and allow the battery

Modeling and Control of Bidirectional Isolated Battery

A transformer, which increases the system size and reduces the and current for battery charging and discharging control. The grid current is always in-phase with the grid voltage for unity

How do charging and discharging patterns

Jan 8, 2025 · Charging and discharging patterns significantly impact the lifespan of batteries, particularly those using lithium-ion technology. Here''s how these

Fault Currents from Battery Energy Storage Systems charging vs discharging

Apr 7, 2008 · When looking at grid connected Battery Energy Storage Systems (BESS) i''m trying to understand if there are any differences in battery contribution to faults occurring on AC

High-Voltage Batteries for Solar Systems: Are They Worth It?

Sep 27, 2024 · The two main drawbacks are: High Cost High-voltage systems are nearly twice as expensive as low-voltage alternatives of the same capacity. Additionally, they often require

6 FAQs about [High voltage inverter charging and discharging]

What is a high-voltage DC link?

Image used courtesy of Adobe Stock High-voltage DC links are central to a wide range of power electronic systems in electric and hybrid vehicles—including inverters relying on large capacitors (e.g 1 mF) to stabilize the voltage, reduce ripple, and support efficient control and operation.

Can a distributed DC grid system improve high-voltage power conversion?

A distributed DC grid system could greatly simplify high-voltage power conversion and increase system availability and reliability. Beyond system architecture innovations, control system innovations are another way to simplify and improve high voltage power-conversion systems.

What is a DC-link capacitor in a traction inverter?

Figure 1. Simplified Block Diagram of a Traction Inverter The DC-Link capacitor is a part of every traction inverter and is positioned in parallel with the high-voltage battery and the power stage (see Figure 1). The DC-Link capacitor has several functions, such as to help smooth voltage ripples, filtering unwanted harmonics and reducing noise.

What is s6-eh3p (12-20)K-H series energy storage inverter?

S6-EH3P (12-20)K-H series three-phase energy storage inverter, suitable for large residential and small commercial PV energy storage systems.

Does a coupled inductor high-gain converter work for EV batteries?

The proposed coupled inductor high-gain converter minimizes ripples and operates efficiently but lacks consideration for heat management, long-term reliability, power scaling, and compatibility with modern EV batteries.

What are examples of high-voltage systems?

A few examples of high-voltage systems widely applied in today’s power networks include residential AC distribution power systems, telecommunication and server power systems, DC microgrids in renewable energy systems, energy storage systems, and electric vehicle (EV) onboard and offboard chargers.

Update Information

- Household charging and discharging dual-purpose inverter

- 10kw three-phase high voltage inverter

- What inverter is used for high voltage grid connection

- Wide voltage and high power inverter

- High voltage power inverter

- High frequency inverter adjusts output voltage

- Can the inverter change to high voltage

- 100kv ultra high voltage inverter price

- EK inverter genuine high voltage

- Working function of high voltage inverter

- High voltage inverter sm

- 12v inverter voltage high

- Household high voltage off-grid inverter

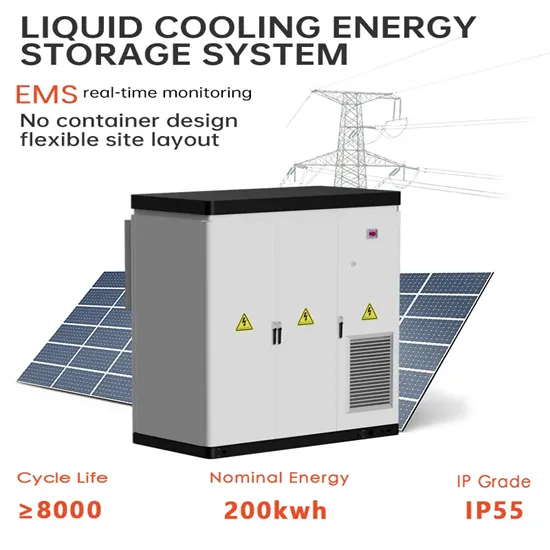

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.