The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

Improved Performance of Bifacial Photovoltaic

Sep 27, 2024 · Bifacial photovoltaic (PV) modules can capture both front and rear incident light simultaneously, thereby enhancing their power output. Achieving

Trina Solar Vertex+ 440 Wp I bifacial double glass solar module

The bifacial double glass solar module actively utilises the reflective light from surrounding surfaces such as snow or the ground. This property increases energy generation beyond

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Reducing the temperature of monofacial double-glass photovoltaic module

Apr 1, 2025 · Al foil improves the heat dissipation along the in-plane direction and achieves a temperature difference reduction of 6.170 ℃ on the whole PV module. This demonstrates that

Enhancing Solar Photovoltaic Efficiency: A

Dec 27, 2024 · However, the efficiency of commercial solar photovoltaic (PV) modules is hindered by several factors, notably their conversion efficiency, which averages around 19%. This

Thermal and electrical performance analysis of monofacial

Sep 27, 2023 · The monofacial double-glass photovoltaic modules are still seriously affected by the temperature effect. The coatings with spectral regulation characteristics are expected to

Thermal and electrical performance analysis of monofacial

Nov 1, 2023 · The monofacial double-glass photovoltaic modules are still seriously affected by the temperature effect. The coatings with spectral regulation characteristics are expected to

Analysis of water and refrigerant-based PV/T systems with double glass

Jan 15, 2024 · Furthermore, the design of the PV/T collector in this research study involved the utilization of a double glass PV module instead of a tedlar back sheet PV module. Based on

Photovoltaic glass: the perfect fusion between

Aug 18, 2025 · These photovoltaic modules use high-efficiency monocrystalline silicon cells (the cells are made of a single crystal of very high-purity silicon) to

Low Temperature Solar Cell Encapsulation with Novel

Mar 29, 2023 · The properties of silicone encapsulants in operating PV modules have been observed to degrade very little over long periods of time [1], resulting in modules showing

双面双玻太阳能光伏组件能效提升综述

双面双玻太阳能光伏组件能效提升综述 认领 被引量: 4 Overview of Energy Efficiency Improvement of Double-Sided Double-Glass Solar Photovoltaic Modules 在线阅读 下载PDF 引

Performance analysis of a heat pump-based photovoltaic/thermal (PV

Apr 2, 2020 · The prototype of the PV/T–SAHP was fabricated with a double glass PV module instead of a conventional module with polyvinyl fluoride backsheet. Initially, the performance

For N-type Bifacial Technology, Dual Glass Structure is

Feb 28, 2023 · A glass/backsheet structure works well with conventional PERC modules due to its lightweight, whereas a glass/glass structure has the potential to generate additional energy for

Crystal Clear Efficiency: The Power of Double Glass Solar Panels

At the heart of double glass solar panels is a design that pairs energy efficiency with enhanced durability. The double-layered glass encapsulation not only boosts the panels'' insulation

Finite Element Modeling, Thermal–Mechanical Coupling

Jul 25, 2022 · The gap-free interconnect using structural round ribbons in overlapping photovoltaic modules is an effective measure to improve module efficiency. Cells in the overlapping module

Thermal and electrical performance analysis of monofacial double-glass

Nov 1, 2023 · Spectral regulation methods were analyzed for cooling monofacial double-glass module. A coupled thermal-electrical model was established to evaluate the performance.

High performance double-glass bifacial PV modules

Oct 5, 2016 · Double-glass structure shows a loss of ~ 1.30% compare to the glass/backsheet structure under STC measurements. J. P. Singh, et al. "Comparison of Glass/glass and

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Assessing the sustainability of solar photovoltaics: the case of glass

Sep 12, 2024 · The life cycles of glass–glass (GG) and standard (STD) solar photovoltaic (PV) panels, consisting of stages from the production of feedstock to solar PV panel utilization, are

How to improve the power generation efficiency of double-sided double

Compared with traditional photovoltaic modules, this series of modules has achieved a significant improvement in power generation efficiency, bringing new breakthroughs to the photovoltaic

How does the double-glass construction affect the energy

Jan 1, 2025 · In conclusion, the double-glass construction of bifacial solar panels boosts energy production efficiency primarily through bifacial light capture and improves reliability and

6 FAQs about [Double-glass photovoltaic module efficiency improvement]

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

What is the electrical performance of BYD double-glass modules?

The electrical performance of the BYD double-glass modules was as expected for multicrystalline cells, with power bins ranging from 245W to 265W for 60-cell modules, and from 295W to 315W for 72-cell modules. The modules were subjected to numerous accelerated ageing tests.

Are early PV modules encapsulated with silicone?

Photovoltaics International Early PV modules were often encapsulated with silicone, and have demonstrated outstanding stability in the field, with degradation rates over 20 to 30 years that are much lower than the typical degradation rates for EVA-encapsulated modules [3–5].

What is glass–glass module technology?

In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability. The concept enables safe module operation at a system voltage of 1,500V, as well as innovative, low-cost module mounting through pad bonding.

What encapsulant materials can be used for PV modules?

Various encapsulant materials can be considered. Polyvinyl butyral (PVB) has been used for a long time for glass–glass PV modules, particularly for thin-film modules.

Update Information

- Photovoltaic module factory cost reduction and efficiency improvement project

- Double-glass photovoltaic module efficiency

- Polycrystalline silicon photovoltaic module cell efficiency

- Double-glass photovoltaic thin-film module price

- How much electricity does a photovoltaic double-glass module generate

- Double-glass module power generation efficiency

- Malabo High Efficiency Photovoltaic Module Project

- Photovoltaic double-glass module back connector

- Double-glass photovoltaic module bending

- Photovoltaic module double glass insulation

- There are several types of photovoltaic module glass

- How much does the third generation photovoltaic module cost

- Photovoltaic module panels produced in Thimphu

Solar Storage Container Market Growth

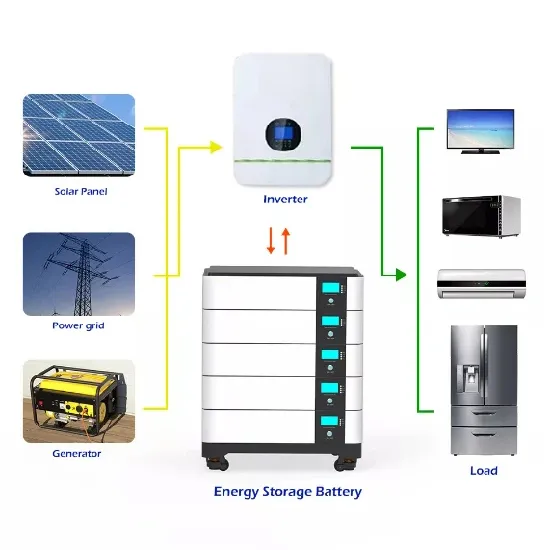

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

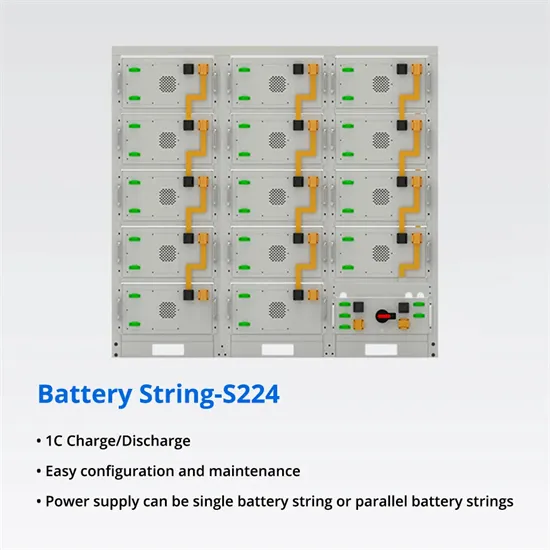

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.