Performance Investigation of Monocrystalline and Polycrystalline PV

Nov 13, 2024 · Passivated Emitter and Rear Cell PV technology (PERC) is one such high efficiency crystalline PV design that is dominating almost 60% market share. The present

What are polycrystalline solar panels?

May 17, 2025 · The photovoltaic (PV) cell layer in solar panels uses a silicon crystal to capture sunlight and convert it to electricity. In polycrystalline panels, the sheet is made by melting

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Despite having lower conversion efficiencies, polycrystalline silicon PV modules are still more efficient than single crystalline silicon PV modules,

Advancements in silicon solar cells: efficiency enhancements

Jun 25, 2025 · Polycrystalline silicon (pc-Si) solar cells typically exhibit high reflectance (30%) of incident sunlight, reducing their energy conversion efficiency. To address this, TiO₂/PVA

Advances in crystalline silicon solar cell technology for

Jul 22, 2010 · Various technologies for mono- and polycrystalline PV cells are compared and discussed with respect to the corresponding material technologies, such as silicon ingot and

A Comparative Analysis and Performance of

Mar 7, 2022 · Abstract:- The spectrum of solar energy is quite wide and its intensity varies according to the timings of the day and geographic locations. This solar energy can be

Performance Investigation of Monocrystalline and Polycrystalline PV

Nov 13, 2024 · Crystalline silicon PV module dominates PV technology worldwide and are constantly emerging with innovative PV designs. Passivated Emitter and Rear Cell PV

Temperature distribution and back sheet role of polycrystalline silicon

Jan 25, 2017 · Some factors affecting properties of solar cells have been studied in our group [9], [10]. This paper established a three dimensional thermal model for the polycrystalline silicon

Performance of Polycrystalline Silicon Material Derived PV Modules

Feb 17, 2025 · The paper presents operating performance of polycrystalline silicon based solar PV modules under variable temperature and irradiance conditions. Annual energy generation

(PDF) Comparative Analysis of Solar Cell Efficiency between

Dec 4, 2020 · The purpose of this study was to examine the effect of light intensity on the output power and efficiency of solar panels. This study applies a direct measurement method using a

Performance comparison of monocrystalline and polycrystalline

Nov 23, 2024 · According to Pastuszak (Pastuszak & Węgierek, 2022), in the article ''Photovoltaic Cell Generations and Current Research Directions for Their Development'', there have been

Energy Production and Performance of Polycrystalline

Aug 23, 2013 · In this paper, the actual electrical performance data of polycrystalline-silicon (poly-c-Si) PV modules measured in situ are featured and compared. Module energy production,

Photovoltaic efficiency enhancement of polycrystalline silicon

Jan 21, 2020 · 本文中, 我们制备了一种高度稳定的EVA/Eu (ND) 4 -CTAC发光薄膜, 将其覆盖在大尺寸的多晶硅太阳能电池表面 (110 cm2)可以使得光电转化效率从15.06%提高到15.57%.

(PDF) Comparative Analysis of Solar Cell Efficiency between

Dec 4, 2020 · There are various types of solar photovoltaic (PV) technologies available for commercial applications, such as organic solar cells, silicon-based solar cells, dye-sensitized

Polycrystalline silicon solar cells

Jan 1, 2021 · In 1990, the conversion efficiency of laboratory cells increased by 35% with 5 mm 2. After that, the manufacturing technology of polycrystalline silicon cells became interesting for

Individual efficiencies of a polycrystalline silicon PV cell versus

Aug 1, 2021 · The present paper is about an investigation on the temperature dependence of efficiencies of individual energetic process (Absorption efficiency, Thermalization efficiency,

Polycrystalline solar panels: the expert guide [2025]

Jul 14, 2025 · What are polycrystalline solar panels? Polycrystalline solar panels are the result of melted polysilicon being poured into moulds, which are cut

Polycrystalline Solar Panel: Features, Working Principle,

Sep 19, 2024 · polycrystalline solar panel manufacturers melt multiple silicon fragments together to produce the wafers for these panels, the electrons in each cell will have less space to move.

Evaluation of the Performance of Polycrystalline

Oct 13, 2023 · In arid regions, the behavior of solar panels changes significantly compared to the datasheets provided by the manufacturer. Therefore, the

Polycrystalline Solar Panel: Features, Working

Jun 15, 2024 · Follow this new blog in Linquip to learn more about this type of solar panel. What is a polycrystalline solar panel? Polycrystalline or multi

The difference between monocrystalline silicon

May 24, 2024 · Polycrystalline silicon is a polycrystalline material composed of a large number of small crystals, with a wide range of applications, mainly

Performance Study of Monocrystalline and Polycrystalline Solar PV

Aug 11, 2020 · This paper evaluates the energy performance of two PV module technologies widely used in solar energy installations in Colombia, also commercially available in the

Enhancement of efficiency in monocrystalline silicon

Sep 6, 2024 · Abstract. As the representative of the first generation of solar cells, crystalline silicon solar cells still dominate the photovoltaic market, including monocrystalline and

Structural and efficiency analysis of polycrystalline Si cells

Jun 23, 2025 · Both the crystalline and morphological properties of ARC-coated and uncoated silicon photovoltaic cells are analysed by X-ray diffraction (XRD) and scanning electron

6 FAQs about [Polycrystalline silicon photovoltaic module cell efficiency]

How efficient are polycrystalline solar cells?

Polycrystalline solar cells have an efficiency range of 12% to 21%. They are often produced by recycling discarded electronic components—known as "silicon scraps"—which are remelted to create a uniform crystalline structure.

What is the temperature dependence of a polycrystalline silicon solar cell?

The temperature dependence of individual efficiencies (Absorption efficiency, Thermalization efficiency, Thermodynamic efficiency and Fill factor) and overall conversion efficiency of a polycrystalline silicon solar cell has been investigated in temperature range 10–50 °C. The all efficiencies present a decrease versus temperature increase.

What is crystalline silicon PV module?

Abstract: Crystalline silicon PV module dominates PV technology worldwide and are constantly emerging with innovative PV designs. Passivated Emitter and Rear Cell PV technology (PERC) is one such high efficiency crystalline PV design that is dominating almost 60% market share.

Does polycrystalline silicon PV cell support temperature increase more than monocrystalline PV cell?

Some studies have shown that the polycrystalline PV cell supports the temperature increase more than the monocrystalline PV cell. The base doping level on which the open circuit voltage depends can be used to improve the temperature resistivity of the polycrystalline silicon PV cell.

What is the power conversion efficiency of a monocrystalline solar cell?

They have demonstrated the power conversion efficiency for the monocrystalline solar cell panel is 12.84%, while the power conversion efficiency for the monocrystalline solar cell panel is 11.95% [18, 29]. This study illustrates the important parameters for upgrading solar cell efficiency.

What is a silicon photovoltaic (PV) solar cell?

Introduction The silicon photovoltaic (PV) solar cell is one of the technologies are dominating the PV market. The mono-Si solar cell is the most efficient of the solar cells into the silicon range. The efficiency of the single-junction terrestrial crystalline silicon PV cell is around 26% today (Green et al., 2019, Green et al., 2020).

Update Information

- Polycrystalline 280w photovoltaic cell module unit price

- What is the cell of photovoltaic module obb

- Albania crystalline silicon photovoltaic module prices

- Photovoltaic cell module grade

- N Djamena polycrystalline photovoltaic module glass

- Kathmandu polycrystalline silicon solar photovoltaic panels

- Which photovoltaic cell module is better

- Photovoltaic module cell processing platform

- Double-glass photovoltaic module efficiency

- Malabo High Efficiency Photovoltaic Module Project

- Senegal polycrystalline photovoltaic module panels

- Photovoltaic Module Innovation and Entrepreneurship Project

- Number of photovoltaic module cells

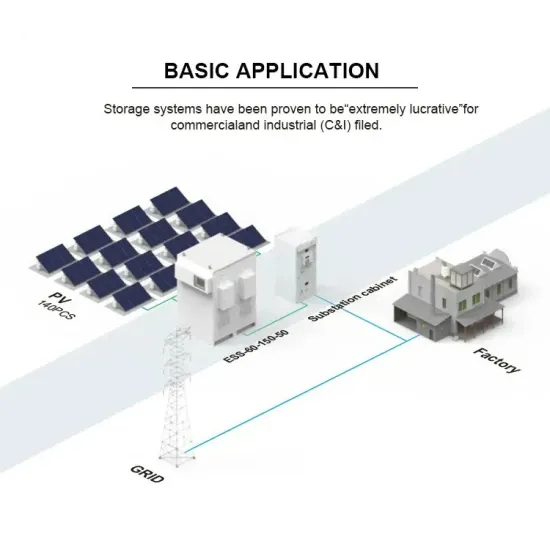

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.