What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · 1.1.7 Summary The factors determining the performance of crystalline silicon solar photovoltaic cells are various factors related to the conversion efficiency of light energy. The

Double-glass PV modules with silicone encapsulation

May 21, 2024 · These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is

Types of Photovoltaic (PV) Module

photovoltaic (PV) module types: including monocrystalline silicon, polycrystalline silicon, thin-film, amorphous silicon, cadmium telluride, CIGS, bifacial, and high-efficiency modules for your

Solar Photovoltaic Glass: Classification and Applications

Jun 26, 2024 · Depending on their properties and manufacturing methods, photovoltaic glass can be categorized into three main types: cover plates for flat-panel solar cells, usually made of

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · The encapsulated glass used in solar photovoltaic modules (or custom solar panels), the current mainstream products are low-iron tempered embossed glass, the solar

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

The 6 types of solar panels | What''s the best

Jun 12, 2025 · What are the main types of solar panels? The six main types of solar panels are polycrystalline, monocrystalline, thin-film, transparent, solar

An overall introduction to photovoltaic glass –

Jan 24, 2024 · Photovoltaic glass refers to the glass used on solar photovoltaic modules, which has the important value of protecting cells and transmitting

Solar Glass: applications and comparison to Light-Trapping

Apr 4, 2024 · 1. Different types of solar glass include tempered glass, low-iron glass, anti-reflective glass, bifacial glass, and heat-strengthened glass.2. Tempered glass offers increased

Tough Break: Many Factors Make Glass Breakage More

Nov 27, 2024 · We have seen cases of the glass in solar panels (photovoltaic [PV] modules) breaking differently, and more often, than it did 5 years ago. There have been many changes

An Extensive Guide to Different Types of Solar

Jul 1, 2024 · Solar panels, or photovoltaic (PV) modules, are devices commonly used on rooftops to collect sunlight and convert it into electricity. First invented

Photovoltaics: Basic Principles and Components

Oct 14, 2013 · Photovoltaics: Basic Design Principles and Components If you are thinking of generating your own electricity, you should consider a photovoltaic (PV) system—a way to gen

Module Materials

Aug 10, 2025 · In most modules the front surface is used to provide the mechanical strength and rigidity, therefore either the top surface or the rear surface must be mechanically rigid in order

What are the Different Types of Solar

Sep 29, 2024 · There are several different types of solar panel including tiles, film, and lightweight. The main difference in solar panels is the purity or alignment

A review of solar photovoltaic technologies: developments,

Jul 1, 2025 · The role of solar PV in the global energy transitions was highlighted. Solar photovoltaic (PV) technology has emerged as a key renewable energy solution, yet its

Overview of PV module encapsulation materials

May 21, 2024 · PV module set-up the longest cycle time. The main goal of Crystalline silicon (c-Si) PV modules Production process equipment producers is to decrease the typically consist of a

An overall introduction to photovoltaic glass – TYCORUN

Jan 24, 2024 · Photovoltaic glass refers to the glass used on solar photovoltaic modules, which has the important value of protecting cells and transmitting light. This article will give you a

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency. Advances in glass compositions, including

6 FAQs about [There are several types of photovoltaic module glass]

What encapsulated glass is used in solar photovoltaic modules?

The encapsulated glass used in solar photovoltaic modules (or custom solar panels), the current mainstream products are low-iron tempered embossed glass, the solar cell module has high requirements for the transmittance of tempered glass, which must be greater than 91.6%, and has a higher reflection for infrared light greater than 1200 nm. rate.

What is Solar Photovoltaic Glass?

This article explores the classification and applications of solar photovoltaic glass. Photovoltaic glass substrates used in solar cells typically include ultra-thin glass, surface-coated glass, and low-iron (extra-clear) glass.

What type of glass is used in solar panels?

The type of solar glass directly influences the amount of solar radiation that is being transmitted. To ensure high solar energy transmittance, glass with low iron oxide is typically used in solar panel manufacturing. Solar panels are made of tempered glass, which is sometimes called toughened glass.

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

What are the different types of Photovoltaic Glass?

These three products have entirely different characteristics and functions, leading to significant differences in their added value. Currently, the most widely used photovoltaic glass is high-transparency glass, known as low-iron glass or extra-clear glass. Iron in ordinary glass, excluding heat-absorbing glass, is considered an impurity.

What is solar glass?

Solar Glass is one of the crucial barriers of traditional solar panels protecting solar cells against harmful externalities, such as water, vapor and dirt.

Update Information

- Bulgarian thin film photovoltaic module glass

- Photovoltaic module glass separation equipment

- N Djamena polycrystalline photovoltaic module glass

- Tunisia double glass photovoltaic module price

- Production of photovoltaic module glass

- How many types of photovoltaic module cells are there

- Cambodia glass photovoltaic module panels

- Tuvalu double glass photovoltaic module manufacturer

- Bloemfontein double glass photovoltaic module manufacturer

- Glass photovoltaic module installation angle

- Photovoltaic glass thickness specifications

- Photovoltaic Glass EK

- Antimony photovoltaic glass

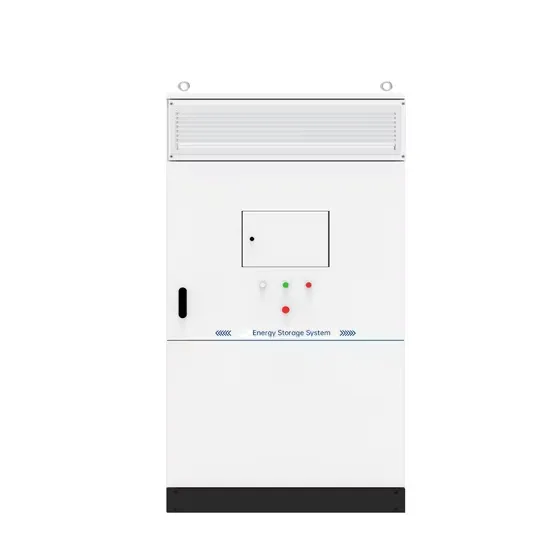

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.