What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each. Some

Reducing the temperature of monofacial double-glass photovoltaic module

Apr 1, 2025 · The temperature distribution of the standard monofacial double-glass PV mini module, CAE PV mini module, and EAG PV mini module was simulated by using the

Double-Glass-Solar-Modules-Installation-Manual

Jun 5, 2025 · The Solarspace Double Glass Photovoltaic Modules Installation Manual provides comprehensive guidelines for the installation, safety, and maintenance of solar PV modules. It

Solarspace Double Glass Photovoltaic Modules

Jun 17, 2025 · Glass surfaces and supports may generate high temperatures, and may be hazardous to burns and electric shocks; −Touching Modules live parts, such as connectors,

Explosion-proof double glass photovoltaic module of

The invention particularly relates to a lightweight explosion-proof double-glass photovoltaic module, comprising an upper explosion-proof glass, a lower explosion-proof glass, a solar

JA SOLAR PV BIFACIAL DOUBLE-GLASS MODULES

Mar 31, 2025 · Installers should follow all safety precautions described in this guide as well as local codes when installing a module. Installing solar photovoltaic systems requires specialized

JA SOLAR PV BIFACIAL DOUBLE-GLASS MODULES

Mar 31, 2025 · In order to ensure the stability and safety of photovoltaic modules, and to prevent the potential risk on PV modules, Photovoltaic mounting system design must strictly follow the

Photovoltaic Glass: A Sustainable and Innovative

Aug 4, 2020 · Photovoltaic glass is a sustainable building material that can generate electricity while also providing light and insulation. It is a great option

INSTRUCTIONS FOR PREPARATION OF PAPERS

Jul 12, 2025 · The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum

A Quantitative Comparison Between Double Glass Photovoltaic Modules

Jul 27, 2017 · The use of half-size silicon (Si) wafer solar cells in photovoltaic (PV) modules can enhance the output power compared to full-size Si wafer solar cells. In this paper, an optimal

Installation Manual( Double glass PV module)

Mar 9, 2023 · The Purpose This installation manual provides installation instructions for the double glass solar modules (hereinafter referred to as double glass PV modules) of Ningbo

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · Canadian Solar''s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

What is photovoltaic double glass panel technology

What is photovoltaic double glass panel technology Glass-glass module structures (Glass Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of

Crystal Clear Efficiency: The Power of Double Glass Solar Panels

At the heart of double glass solar panels is a design that pairs energy efficiency with enhanced durability. The double-layered glass encapsulation not only boosts the panels'' insulation

Installation Manual( Double glass PV module)

Dec 16, 2020 · The Purpose This installation manual provides installation instructions for the double glass solar modules (hereinafter referred to as double glass PV modules) of Ningbo

Multi-objective evolutionary optimization of photovoltaic glass

Nov 1, 2023 · Optimized results of low-E semi-transparent amorphous-silicon photovoltaic glass applied on the façade show that the spatial daylight autonomy is increased to 82% with

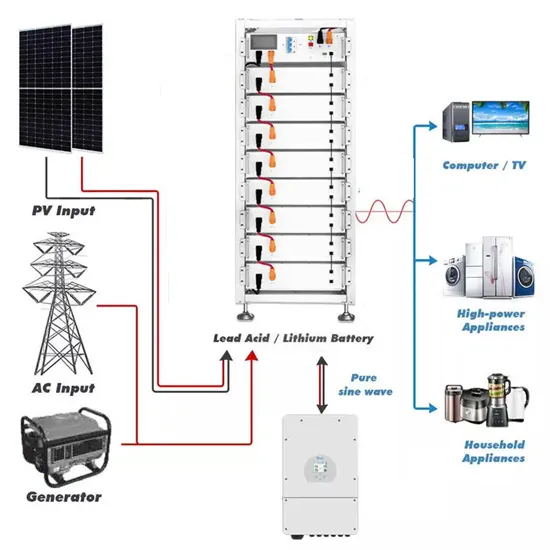

Double Glass PV Module Installation Introduction

Sep 8, 2018 · Double Glass PV System configuration should follow suggestions from battery manufacture when using storage battery in photovoltaic system. DO NOT replace parts of or

Experimental investigation on the combustion performance

Jun 15, 2025 · Under similar glass material conditions, double-glazed modules exhibited superior combustion performance compared to their single-glass counterparts. Therefore, locations

Hotspot testing of glass/backsheet and glass/glass PV modules

Jan 1, 2023 · Continuous advances in the crystalline silicon photovoltaic (PV) module designs and economies of scale are driving down the cost of PV electricity and improving its reliability

6 FAQs about [Photovoltaic module double glass insulation]

What is double glass photovoltaic module?

Preface To further extend the s rvice life of photovoltaic modules, double glass photovoltaic module has cently been develop d and st died in the PV community. Double lass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet.

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What is a double-glass solar module?

ABSTRACT: Double-glass modules provide a heavy-duty solution for harsh environments with high temperature, high humidity or high UV conditions that usually impact the reliability of traditional solar modules with backsheet material.

What is a dual-glass module?

Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each. Some manufacturers, in order to reduce the weight of the modules, have opted for a thickness of 1.6 mm. DualSun has chosen to stay with a thickness of 2.0 mm for reasons explained below.

How reliable is Canadian Solar's Dymond double glass module?

Canadian Solar’s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully indicate high lifetime and high reliability of this double glass module. This paper presents a detailed reliability study of Canadian Solar’s Dymond double glass module.

Are double glass PV modules safe?

Double glass PV modules is an area of significant investigation by many companies and institutes in recent years, for example Dupont, Trina, Apollon, SERIS, MIT, Meyer Burger and Talesun. According to the literature, double glass also has some potential risks besides the abovementioned advantages.

Update Information

- Kinshasa double glass photovoltaic module price

- Southern Europe Double Glass Photovoltaic Module Company

- Tunisia double glass photovoltaic module price

- Tuvalu double glass photovoltaic module manufacturer

- Double glass module structure

- What is the current price of single crystal double glass photovoltaic panels

- Amorphous silicon cell double glass module

- Sri Lanka double glass photovoltaic curtain wall supplier

- Is the double glass module good

- Malta double glass photovoltaic curtain wall customization

- Double glass photovoltaic power generation installation

- Niamey standard photovoltaic module glass

- Photovoltaic panel double glass size standard

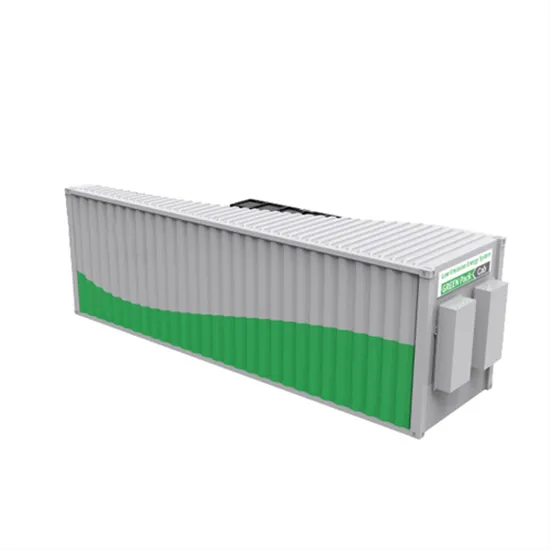

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.