Analysis of the Impact Resistance of Photovoltaic

Jul 27, 2021 · The double-glass photovoltaic module is equivalent to a single-layer board, and its effectiveness is verified by comparing the impact test

Double Glass Module Bus-Bar Bending&Cutting Machine

Jul 30, 2025 · Double Glass Module Bus-Bar Bending&Cutting Machine, Find Details and Price about Bus-Bar Bending&Cutting Machine Bus-Bar Cutting Machine from Double Glass Module

T/ZBH 026-2023 晶硅光伏组件用材料 第3部分:双玻光伏组件

Jan 1, 2023 · Materials for crystalline silicon photovoltaic modules Part 3: Technical specifications for bending strength, impact resistance and surface stress of rolled glass for double-glass

Comparative Study on Static and Dynamic Analyses of

Dec 29, 2023 · Abstract This paper presents a numerical simulation work on the mechanical behaviors of an ultra-thin double-glazing PV module under static and dynamic load conditions.

Effects of Photovoltaic Module Materials and Design on Module

Feb 27, 2020 · The double-glass photovoltaic module is equivalent to a single-layer board, and its effectiveness is verified by comparing the impact test results of the double-glass photovoltaic

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Quantifying the reliability of photovoltaic (PV) modules is essential for consistent electrical performance and achieving long operational lifetimes.

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

Experimental and Theoretical Research on Bending

Aug 22, 2023 · Therefore, the PV panels studied in the present paper focusing on BIPV are double glass PV module which consists of two glasses and an interlayer in where the cells are

Photovoltaic double-hole bending plate construction

present paper, the bending behavior of double glass PV panel is studied carefully by both experimental and theoretical research. Different from many previous researches, a special

Photovoltaic puncture bending plate use

The bending test of PV panel is performed at room temperature to verify the structural analysis results aforementioned and detect the real mechanical properties. The 6 specimens are all the

High performance double-glass bifacial PV modules

Oct 5, 2016 · Double-glass structure shows a loss of ~ 1.30% compare to the glass/backsheet structure under STC measurements. J. P. Singh, et al. "Comparison of Glass/glass and

Manufacturing Induced Bending Stresses: Glass-Glass vs. Glass

Jun 25, 2021 · The architecture of a photovoltaic module directly influences its mechanical stability, affecting cell crack propagation and contributing to the existence and d

(PDF) Experimental and theoretical research on bending behaviour

Aug 19, 2019 · The designed fracture of laminated glass (LG) makes it useful for architectural, glazing, automotive safety, photovoltaic, ultraviolet ray protection, and decorative applications.

Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · Solar photovoltaic (PV) energy is a crucial supply technology in the envisioned renewable energy system. With enormous amounts of PV modules being installed, some will

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Lamination preparation process of curved-surface double-glass

The lamination preparation process of the curved-surface double-glass photovoltaic module can utilize one device to prepare photovoltaic modules with different radiuses of curvature.

Photovoltaic glass S-bend adjustment

What is the bending behaviour of double glass PV panel? A mechanical model is built to describe the bending behaviour of the double glass PV panel under uniformly distributed force, and

Experimental and Theoretical Research on Bending

As to the bottom plate, it can be made of the transparent glass or opaque TPT, which makes double glass PV module or single glass PV module. Due to the requirements of lighting inside

Modelling of a double-glass photovoltaic module using finite

Dec 1, 2005 · A simulation model of finite differences describing a double-glass multi-crystalline photovoltaic module has been developed and validated using experimental data from such a

Photovoltaic panel purlin deflection limit

What is the size of a double glass photovoltaic module? Technology Co.,Ltd (Changshu,P.R. China). The size of the 6 specimens are 1658×995×7.4(unit: mm),in which the

Reasons for bending of glass photovoltaic panels

In present paper, the bending behavior of double glass PV panel is studied carefully by both experimental and theoretical research. Different from many previous researches, a special

Photovoltaic double-hole bending plate construction

The main difference between building attached photovoltaic (BAPV) and BIPV is that the photovoltaic (PV) module is designed and constructed with buildings at the same time in

T/ZBH 026-2023 晶硅光伏组件用材料 第3部分:双玻光伏组件

Jan 1, 2023 · T/ZBH 026-2023 晶硅光伏组件用材料 第3部分:双玻光伏组件用压延玻璃弯曲强度、抗冲击性及表面应力技术规范 Materials for crystalline silicon photovoltaic modules Part 3:

6 FAQs about [Double-glass photovoltaic module bending]

Are double glass PV panels bending?

Experimental Analysis of Double Glass PV Panel panels, bending testing is performed for 8 specimens at room temperature. The specimens are all the Photovoltaic T echnology Co., Ltd (Changshu, China). Among those specimens, there are 3 specimens 7.4 (unit: mm). The two groups of PV panels are different at the thickness of the glass.

What is a double glass PV module?

Therefore, the PV panels studied in the present paper focusing on BIPV are double glass PV module which consists of two glasses and an interlayer in where the cells are sealed by ethylene vinyl acetate (EVA) or polyvinyl butyral (PVB).

Are double glass PV panels suitable for BIPV?

In BIPV, the double glass PV module with better photopermeability are more suitable and acceptable in the real structures. Therefore, the PV panels studied in the present paper are double glass PV panel which consists of two glasses and an interlayer in where the cells are sealed by ethylene vinyl acetate (EVA) or polyvinyl butyral (PVB).

How is a closed form solution used for bending a photovoltaic panel?

A closed form solution is derived out and used to do the numerical calculation. The corresponding bending experiments of PV panels are completed. Comparing the numerical results with experiment results, the accuracy of the analytical solutions are verified. Structural diagram of monocrystalline silicon double glass photovoltaic panel.

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What are double glass PV panels?

The double glass PV panels are simplified as five layers composite structure, including cover glass, ethylene-vinylacetate (EVA), silicon solar cells, EVA and back glass. Since it’s too thin to make any influence, the battery layer is assumed as a continuous layer.

Update Information

- Double-glass photovoltaic module efficiency

- Double-glass photovoltaic thin-film module price

- Double-glass photovoltaic module manufacturers

- Double-glass photovoltaic module efficiency improvement

- How much electricity does a photovoltaic double-glass module generate

- Nanya double-glass photovoltaic module manufacturer

- Photovoltaic module project in Milan Italy

- Price of one watt photovoltaic module

- Efficiency comparison between double-glass and single-glass photovoltaic modules

- N-type 580wp crystalline silicon photovoltaic module price

- Ukrainian solar photovoltaic module manufacturers

- Photovoltaic thermal bending glass

- Photovoltaic module export specifications

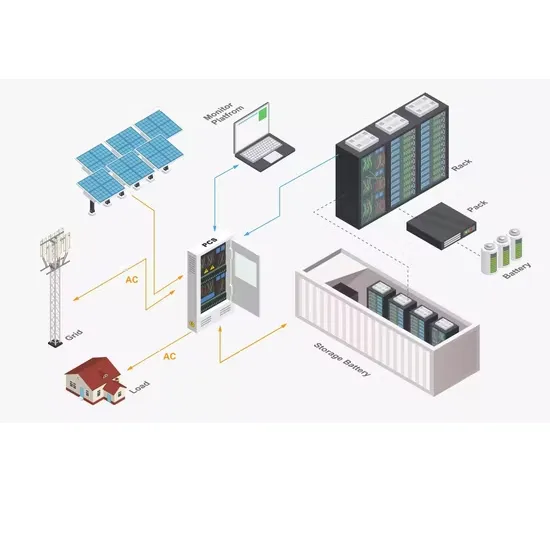

Solar Storage Container Market Growth

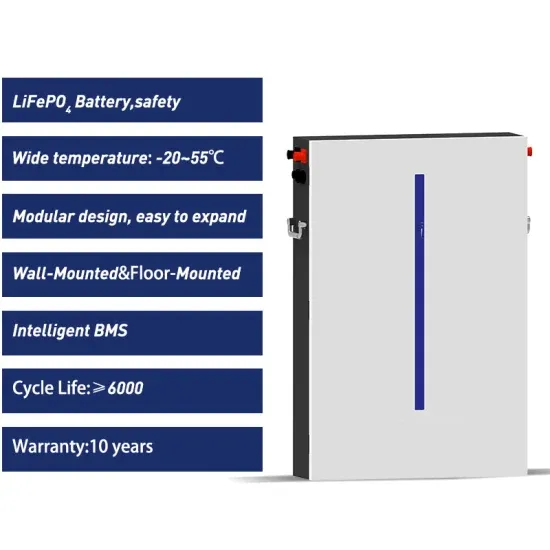

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.