Innovations in Cost Reduction and Efficiency Improvement for Solar Modules

Jul 5, 2024 · The current focus on cost reduction and efficiency improvement in photovoltaic modules revolves around three key areas: silicon wafers, solar cells, and module encapsulation.

Empowering Factories with Solar Energy A Strategic Tool for

Apr 17, 2025 · Due to its high predictability, low marginal cost, and minimal maintenance burden, commercial and industrial solar is becoming a crucial tool for factories to optimize energy use

Progress of PV cell technology: Feasibility of building materials, cost

Jul 1, 2023 · Recently, the demand for PV technology by various sectors, including the public domain, industry, and space technology, has significantly increased. The feasibilities of

Future cost projections for photovoltaic module manufacturing using

Apr 1, 2022 · Photovoltaic module prices have typically decreased faster than projections. There are two methods usually used for these projections; cumulative market shipment experience

Evaluating the causes of cost reduction in photovoltaic modules

Dec 1, 2018 · After 2001, however, scale economies became a more significant cause of cost reduction, approaching R&D in importance. Policies that stimulate market growth have played

Research status and application of rooftop photovoltaic

Aug 1, 2023 · Continuous research and development of PV materials has led to highly efficient solutions for rooftop PV promotion, including the reduction of production costs, improvement of

IRENA Forecasts 59% Solar PV Price Reduction By 2025

Jun 22, 2016 · IRENA states that solar PV module prices have fallen roughly 80% since 2009, and with every doubling of installed capacity module costs plunge a further 20% thanks to

Performance Enhancement and Cost Reduction through Advanced PV

For PV to fulfil its mission in transforming the energy systems and to accommodate large-scale deployment, further cost reduction as well as increased emphasis on efficiency and

Crystalline Silicon Photovoltaic Module Manufacturing

Feb 10, 2020 · Crystalline Silicon Photovoltaic Module Manufacturing Costs and Sustainable Pricing: 1H 2018 Benchmark and Cost Reduction Road Map Michael Woodhouse, Brittany

Innovations in improving photovoltaic efficiency: A review of

Mar 1, 2025 · Using phase change materials improved performance by 35.8 %, while hybrid cooling techniques reduced PV temperatures by an average of 10 °C. Nanofluids enhanced

Review of degradation and failure phenomena in photovoltaic modules

May 1, 2022 · The degradation of photovoltaic (PV) systems is one of the key factors to address in order to reduce the cost of the electricity produced by increasing the operational lifetime of PV

Efficient cost reduction in manufacturing and logistics

Aug 1, 2025 · Cost reduction – a challenge Especially during times of crisis, production companies introduce initiatives to reduce costs in manu-facturing and logistics, or at least to stabilize

CO2 emission reduction effect of photovoltaic industry

Apr 15, 2023 · The novelty of this study is to use life cycle assessment (LCA) methods to analyze the CO2 emission reduction of the PV generation industry before 2060 base on the amount of

Enhancing photovoltaic operation system efficiency and cost

Aug 15, 2024 · The outcomes illustrate that precise control of TECs can increase the electrical output power efficiency of PV modules by 9.27 % while efficiently regulating surface

Six Factors for PV Cost Reduction and Efficiency Increase

Sep 26, 2021 · Photovoltaic enterprises need to pay attention to six key points, such as operation and maintenance cost, whole life power generation hours, high-efficiency inverter, high

Efficiency and Sustainability in Solar Photovoltaic

Mar 6, 2025 · PSS (Photovoltaic Solar Systems) are a key technology in energy transition, and their efficiency depends on multiple interrelated factors. This

Economic analysis of whole-county PV projects in China

Sep 1, 2023 · To discuss the impact of uncertain factors on the economic efficiency of whole-county PV power projects, the green power trading price, self-consumption tariff, proportion of

Recent enhancement in photovoltaic cell efficiency

This review offers depth analysis of recent developments in PV solar cells, focusing on silicon, perovskite, and perovskite/silicon tandem cells. Key factors influencing the commercialization

Six Factors for PV Cost Reduction and Efficiency Increase

Jun 21, 2025 · With the improvement of innovative technologies in the photovoltaic industry, photovoltaic cell modules, manufacturing and production, scale cost, raw material cost, and

Evaluating the causes of cost reduction in photovoltaic modules

Dec 1, 2018 · Improvements to module efficiency in particular would help cut the per-watt cost of all cost components of PV modules (as well as PV systems). Variables that might face

Six Factors for PV Cost Reduction and Efficiency Increase

Sep 26, 2021 · With the improvement of innovative technologies in the photovoltaic industry, photovoltaic cell modules, manufacturing and production, scale cost, raw material cost, and

Technology, cost, economic performance of distributed photovoltaic

Aug 1, 2019 · The application of efficient PV module technology cannot only effectively reduce the cost of PV modules, but also improve the performance and life of PV modules.

Enhancing Solar Photovoltaic Efficiency: A

Dec 27, 2024 · This study investigates the cooling of PV modules by applying water to their front surface through Computational fluid dynamics (CFD). The study aimed to determine the

PV O&M Cost Model and Cost Reduction

Aug 20, 2020 · This is done for each measure in the PV O&M Cost Model (PV module replacement, inverter replacementall) and added up to calculate the total amount in the

Improving photovoltaic module efficiency using water

Dec 2, 2024 · This research investigates the essential role of cooling systems in optimizing the performance of photovoltaic panels, particularly in hot climates. Elevated temperatures on the

Facilitating circularity of end-of-life photovoltaic in China

May 16, 2025 · The rapid growth of global photovoltaic (PV) installation will lead to the emergence of end-of-life (EoL) modules in the coming decades. It is essenti

Photovoltaic supply chain and government subsidy

Aug 10, 2023 · This paper has realized the collaborative improvement of economic and social benefits among many participants in the PV supply chain, which is crucial to encouraging the

Empowering Factories with Solar Energy A Strategic Tool for

Apr 17, 2025 · Commercial and industrial solar is becoming a key solution for factories to reduce electricity costs and hedge against price fluctuations. This article systematically analyzes its

6 FAQs about [Photovoltaic module factory cost reduction and efficiency improvement project]

How did our solar PV module manufacturing plant's financial model work?

Our solar PV module manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs.

What is the production capacity of solar PV module?

The proposed facility is designed with an annual production capacity of 1,000 MW (1 GW) of solar PV module. Manufacturing Process: The first step in the production of solar PV modules is the melting and solidification of high-purity silicon pieces into polycrystalline ingots.

Why is effective control of solar PV costs important?

Effective control of these costs is necessary for maintaining competitiveness and growth. Profitability Analysis Year on Year Basis: The proposed solar PV module plant, with a capacity of 1,000 MW (1 GW) solar PV module annually, achieved an impressive revenue of US$ 169.0 million in its first year.

What are polycrystalline solar photovoltaic (PV) modules?

Polycrystalline solar photovoltaic (PV) modules are a key component of solar energy systems, harnessing sunlight and converting it into electricity through the photovoltaic effect. These modules are composed of multiple interconnected solar cells, each made from polycrystalline silicon.

Can bifacial PV technology improve solar efficiency of building facades?

By combining the advantages of bifacial PV technology's energy generation with the passive temperature response of thermochromic materials, this creative method increased the solar efficiency of building facades. The use of dimples and numerous PCMs to improve bifacial PV systems was investigated by Abo-Elnour et al. .

What is NREL analysis of manufacturing costs for silicon solar cells?

NREL analysis of manufacturing costs for silicon solar cells includes bottom-up cost modeling for all the steps in the silicon value chain. Solar Manufacturing Cost Analysis Solar Installed System Cost Analysis Solar Levelized Cost of Energy Analysis Solar Supply Chain and Industry Analysis Solar System Operations and Maintenance Analysis

Update Information

- Photovoltaic module quality improvement project

- Malabo High Efficiency Photovoltaic Module Project

- Double-glass photovoltaic module efficiency improvement

- Peru Photovoltaic Module Project

- Photovoltaic Module Innovation and Entrepreneurship Project

- Sierra Leone Photovoltaic Module Industry Chain Project

- Photovoltaic module project investment

- Bhutan Photovoltaic Module Procurement Project

- How much does the Hargeisa smart photovoltaic module equipment cost

- Beirut Photovoltaic Module Project

- Dili Solar Photovoltaic Module Factory

- Polycrystalline silicon photovoltaic module cell efficiency

- Advantages of Photovoltaic Module Project

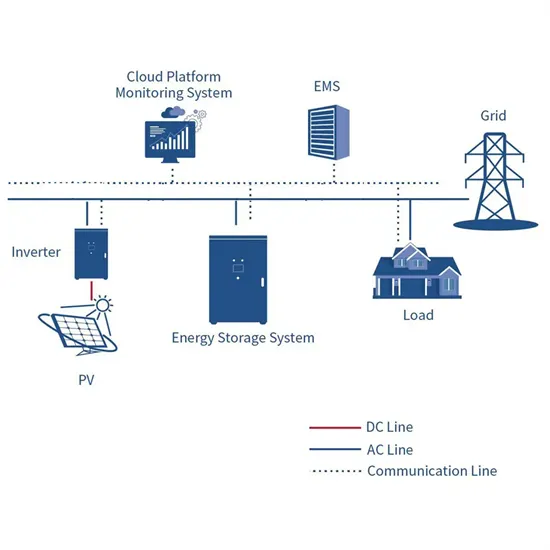

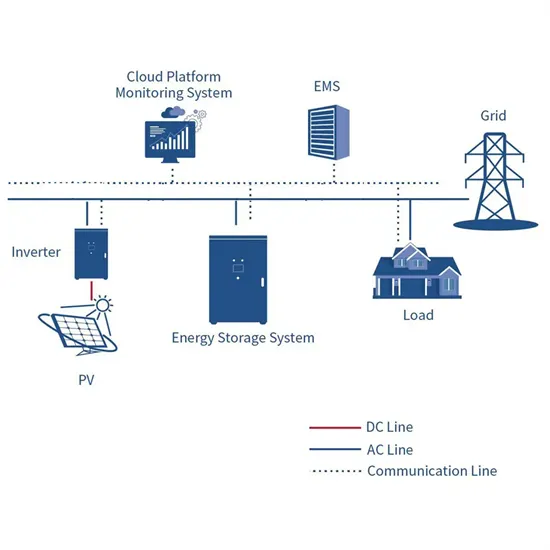

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.