A study of Cell Cracks Formation During Freight Shipping :

Jun 16, 2023 · Abstract: The solar photovoltaic (PV) industry often experiences module damage during transportation. PV modules stacked horizontally and strapped on wooden pallets may

Photovoltaic Panel Transportation Damage Rate: Costs,

Meta description: Discover why 12-30% of solar panels get damaged during transport, how improper logistics cost the industry $2.1B annually, and proven strategies to reduce

Analysis of the hail impacts on the performance of

Feb 1, 2023 · According to the findings, PV modules with a front glass thickness of 3.2 mm are exemplary when hit by hail up to 35 mm in diameter at a velocity of 27 m/s. However, in hail

A Review of Photovoltaic Module Failure and

Jan 9, 2024 · This paper conducts a state-of-the-art literature review to examine PV failures, their types, and their root causes based on the components of PV

Effect of materials and design on PV cracking under

Nov 1, 2022 · Cracking of crystalline silicon (c-Si) solar cells in PV modules is widely reported and it is a well-known problem in the PV industry since it may damage the mechanical integrity of

How to Protect Solar Panels from Damage Transporting and

Jul 16, 2018 · The process of producing a high-quality PV module takes effort and energy to create. Which is why it can be frustrating, for the end-user and manufacturer, when a module

Impact of cracking of photovoltaic panel glass

What causes cell cracks in photovoltaic panels? Cell cracks appear in the photovoltaic (PV) panels during their transportation from the factory to the place of installation. Moreover, some

Prediction of vibration induced damage in photovoltaic

Abstract The transportation of the photovoltaic (PV) modules involves excessive vibrations and shocks. These dynamic loads can crack the solar cells and glass of the PV modules. The

The delicate matter of protecting solar panels

Apr 9, 2024 · For a product made primarily of fragile glass, solar panels can absorb many stressors and still successfully function well beyond their 30-year

Glass/Glass Photovoltaic Module Reliability and

Aug 3, 2021 · In this review, we present the history of G/G modules that have existed in the field for the past 20 years, their subsequent reliability issues

Mechanical integrity of photovoltaic panels under

Feb 29, 2024 · The performance of Photovoltaic (PV) modules heavily relies on their structural strength, manufacturing methods, and materials. Damage induced during their lifecycle leads

The Art of Moving Sunshine: A Step-by-Step Guide to Photovoltaic

Ever tried carrying a 50-pound glass sandwich across a construction site? That''s essentially what manual photovoltaic panel transportation feels like. As solar installations multiply faster than

Environmental impacts of solar photovoltaic systems: A critical review

Mar 10, 2021 · Photovoltaic (PV) systems are regarded as clean and sustainable sources of energy. Although the operation of PV systems exhibits minimal pollution during their lifetime,

Photovoltaic module Recycling: A review on material

The utilization of photovoltaic (PV) modules as a renewable and eco-friendly energy resource has seen a considerable rise lately due to their electricity generation ability without causing any

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged with the growing interest in green energy. This article explores ultra-thin, surface-coated, and

How to protect solar panels from damage during transit

Jun 6, 2022 · Solar PV panels are fragile, and even perfectly produced panels can get damaged, scratched, or non-functional due to poor logistic services. Statistics show that almost 5% of

A Review of Photovoltaic Module Failure and Degradation

Jan 9, 2024 · This paper conducts a state-of-the-art literature review to examine PV failures, their types, and their root causes based on the components of PV modules (from protective glass to

Life cycle assessment and comparison of the conventional

Jan 9, 2025 · Photovoltaic modules face significant performance loss due to the reflection of solar radiation and dust accumulation on the PV glass cover. Micro- and nanoscale texturing of the

Thinner Glass, Larger Sizes Linked to Solar Panel

Dec 13, 2024 · The findings suggest that while thinner glass is cost-effective, it compromises the durability of PV modules, making them more susceptible to

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · 1.1.7 Summary The factors determining the performance of crystalline silicon solar photovoltaic cells are various factors related to the conversion efficiency of light energy. The

6 FAQs about [Photovoltaic glass transportation damage]

Are glass-glass PV modules a problem?

Unfortunately, glass-glass PV modules are, similar to regular PV modules, subject to early life failures. A failure of growing concern are defects in the glass layer (s) of PV modules. The scale of decommissioned PV modules with glass defects will increase with the development of solar PV energy [ 7 ].

How do glass defects affect a PV system?

Glass defects impact the economic performance of a PV system in multiple ways. The most obvious effect is the potential (in)direct performance loss of PV modules, which results in reduced economic revenues. Secondly, PV modules that suffer from glass defects may no longer meet safety requirements, therefore these modules are replaced.

Can PV modules survive a glass defect?

However, glass defects do not directly imply that PV modules endure internal damage nor that PV modules cannot continue to operate with minimal microcracks. Thus far, glass defects have been regarded as a failure beyond repair and no noticeable attempt has been made to develop reparation methods.

Are solar PV panels fragile?

Solar PV panels are fragile, and even perfectly produced panels can get damaged, scratched, or non-functional due to poor logistic services.

Does glass defect reparation damage PV cells?

Furthermore, the research analyzed the economic and energetic impact of glass defect reparation in comparison with regular substitution. We found that glass-glass PV modules which endured glass defects did not show performance loss, nor internal damage to the PV cells.

How common is glass breakage in PV modules?

A customer complaints research, on PV modules after two years of operation, observed glass breakage for 10% of the failure cases [ 28 ]. Another study on PV failures observed an even higher failure-share for glass breakage.

Update Information

- EK Photovoltaic Glass Transportation

- Photovoltaic tempered glass transportation standards

- How much does a photovoltaic tempered glass cost

- Special-shaped photovoltaic glass curtain wall

- There are several types of photovoltaic module glass

- Solar Photovoltaic Glass Separation Plant

- Russia St Petersburg double glass photovoltaic modules

- Cuban photovoltaic broken glass panels for sale

- Kuwait Photovoltaic Glass Project

- Photovoltaic Glass EK

- Photovoltaic 2 5mm glass production

- Is the glass of photovoltaic panels so brittle

- Fiji Photovoltaic Glass Manufacturer

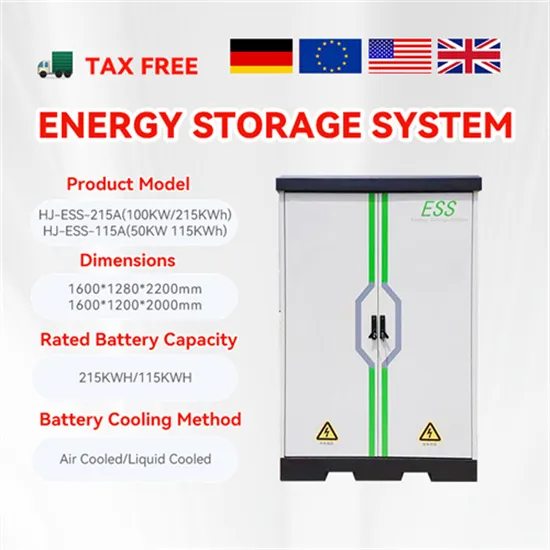

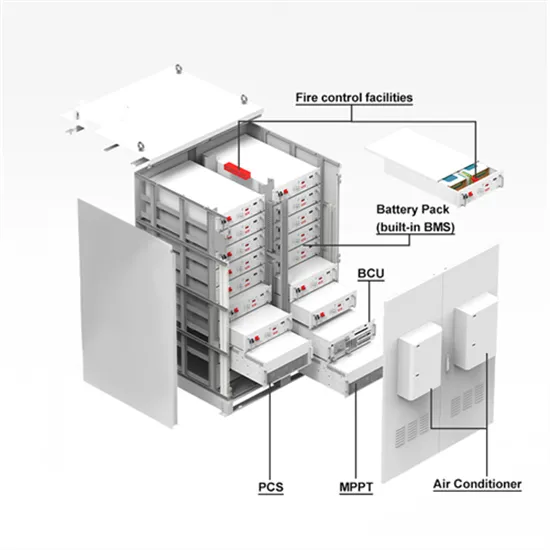

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

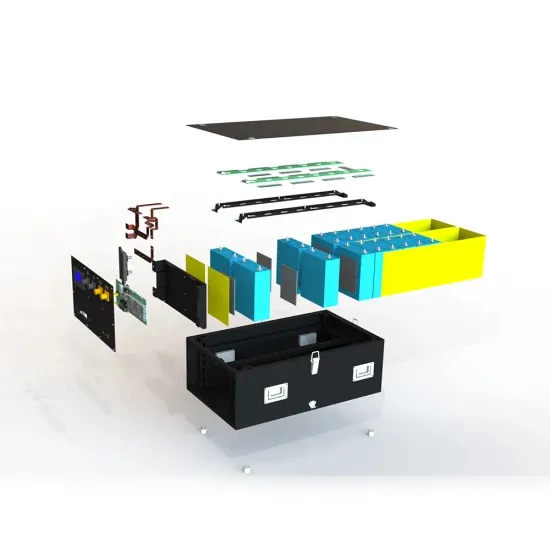

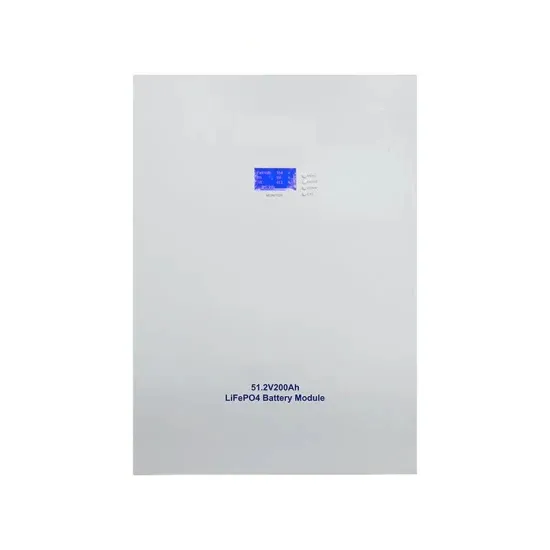

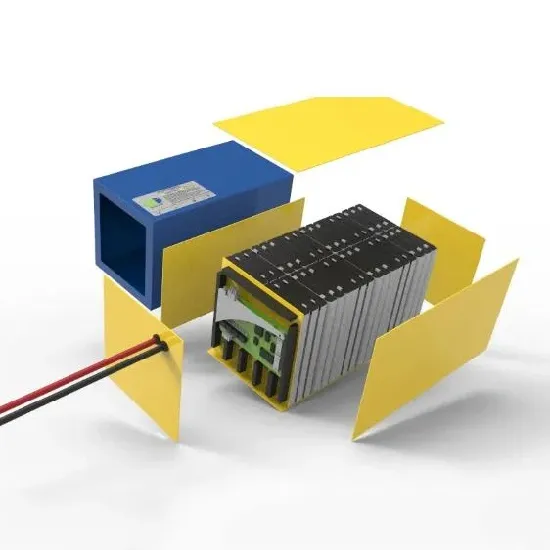

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.