Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · 1. What is solar photovoltaic glass?Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by

Stiffness and fracture analysis of photovoltaic grade silicon plates

Oct 15, 2016 · The rigidity and the strength of photovoltaic cells, particularly the centerpiece-embedded silicon plates, are of great importance from an economical point of view since their

The cheapest photovoltaic glass

A thin-film solar panel is the cheapest type of solar panel on the market so it uses a relatively thin layer of standard glass. Crystalline solar panels commonly use 4 mm glass, making them

Top 5 Factors Responsible for Glass Breakage in Solar Modules

Mar 17, 2025 · Long-Term UV Exposure: Prolonged exposure to strong UV radiation can weaken the protective coatings and make the glass brittle. Acid Rain and Pollution: Chemical reactions

Selective grinding of glass to remove resin for silicon-based

Mar 1, 2021 · Abstract Secondary grinding was investigated as a mean of liberating glass from locked particles of glass and resin obtained by the primary shredding from the silicon-based

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Solar Glass & Mirrors Glass is used in photovoltaic modules as layer of protection against the elements. In thin-film technology, glass also serves as the substrate upon which the

Effect of materials and design on PV cracking under

Nov 1, 2022 · This section describes the geometrical development and validation of FE models for three PV module architecture designs, for a 60-cell crystalline silicon glass-backsheet module,

How does photovoltaic glass compare to traditional

Oct 30, 2024 · In summary,photovoltaic glassoutperforms traditional materials in terms of durability due to its superior strength,weather resistance,longevity,and ability to protect against

Are Solar Panels Fragile?

Aug 12, 2024 · While both are made of glass, solar panels use tempered glass, which is much stronger and more resistant to breakage than the standard glass used in windows. Tempered

Are Glass Solar Panels Fragile-JA TECH

Aug 27, 2024 · Glass, as a hard and brittle material, is fragile under certain conditions. However, the special glass used for solar panels has been strengthened, such as improving its strength

Why are solar panels encased in glass instead of tougher materials

Jan 20, 2020 · Since the solar cells themselves are made primarily of silicon, they have properties very similar to that raw element: stuff and relatively brittle. Glass is also stiff, so much thicker

It''s a new era for solar energy — This flexible cell

Apr 1, 2025 · Solar panels are usually black boards made of monocrystalline silicon photovoltaic cells that capture sunlight and convert it into electrical

Can I still use my solar PV panels with broken glass?

Green and widely sourced solar energy resources have become the new energy source of the 21st century. Solar street light is now the master of lighting in our life, and more and more

Solar PV Backsheet Cracks: Causes & Solutions

Sep 7, 2022 · Learn about the causes of cracks in solar PV backsheets, their impact on performance, and how to ensure durability with high-quality materials.

Why are solar panels so fragile? | NenPower

Jan 16, 2024 · Generally, solar panels comprise silicon-based photovoltaic cells, which convert sunlight into electrical energy. These cells are encased in a protective layer, typically

Mechanical analysis and design of large building integrated

Feb 1, 2023 · The test results showed that the stiffness of large photovoltaic panels is affected by the stiffness of EVA. The work done by Sable et al. (2019) investigated the mechanical

Mechanical analysis and design of large building integrated

Feb 1, 2023 · A building integrated photovoltaic (BIPV) system generally consists of solar cells or modules that are integrated into building elements as part of the building structure (Yin et al.,

How Do We Separate Glass from Backsheets in Solar Panel

Mar 21, 2025 · Solar panels are a key player in clean energy, but what happens when they reach the end of their 25–30-year lifespan? Recycling solar panels is essential to recover valuable

Experimental study of windblown sand erosion on photovoltaic panels

The photovoltaic panel glass (PvPG) is subjected to windblown sand erosion, leading to the formation of surface craters, which can adversely affect the efficiency of photovoltaic power

Optimizing photovoltaic module glass reliability

Sep 10, 2008 · Glass reliability issues can include brittle failure due to mechanical and thermal stresses, surface weathering, lamination adhesion, TCO adhesion, moisture ingress, and anti

Analysis of the Impact Resistance of Photovoltaic Panels

Jul 26, 2021 · Based on the recent development of renewable energy utilization technology, in addition to centralized photovoltaic power plants, distributed photovoltaic power generation

Enabling curvable silicon photovoltaics technology using

May 15, 2021 · Cracks in brittle silicon solar cells (wafers) are a major concern in the solar photovoltaics (PV) industry. Because of the slicing of the wafers from

6 FAQs about [Is the glass of photovoltaic panels so brittle ]

Are transparent photovoltaics good for the environment?

The use of transparent photovoltaics in the US was found to have both environmental and cost benefits due to the combined reduction in building energy consumption and electricity production. Soiling of solar cover glass can result in a significant loss of electrical output of PV panels.

What happens if solar cover glass is soaked?

Soiling of solar cover glass can result in a significant loss of electrical output of PV panels. Dust and other contaminants adhere strongly to the glass by known mechanisms. In contrast, anti-soiling coatings, and the mechanisms by which they function, are not well-characterized.

How tempered glass is used to generate solar power?

This solar power is being generated by converting sunlight into electricity through Photovoltaics (PV) which is also called as solar cells. Solar cells comprise of many parts from which tempered glass is the one whose high strength acts as a shield for the solar modules by protecting them from mechanical loads and extreme weather conditions.

Why is photovoltaic glazing used in modern architecture?

Photovoltaics (PVs) usage has worldwidely spread thanks to the efficiency and reliability increase and price decrease of solar panels. The photovoltaic (PV) glazing technique is a preferred method in modern architecture because of its aesthetic properties besides electricity generation.

Can low-cost PV cells be used for solar control glass?

The development of low-cost PV cells for the production of cost-effective and energy-saving glass systems has been of great interest. Solar control glass which is one of the crucial components of PV panels is largely employed for architectural and automotive windows to lower the sunlight and heat inlet for the comfort.

Is epoxy solar glass a good alternative to tempered glass?

Variation in these properties has been found especially due to the absorption and reflection in the visible spectrum. But, looking at other aspects such as facile fabrication, cost-effectiveness and availability, the epoxy solar glass can be suggested for an alternative source in place of tempered glass in solar panels.

Update Information

- Are the glass of double-glass photovoltaic panels divided into upper and lower parts

- Photovoltaic panels have been removed from the glass

- Glass curtain wall plus photovoltaic panels

- Photovoltaic panels to glass

- Production of photovoltaic glass panels

- Advantages of photovoltaic glass panels

- Cambodia glass photovoltaic module panels

- Cuban photovoltaic broken glass panels for sale

- Differences between photovoltaic glass panels in Aarhus Denmark

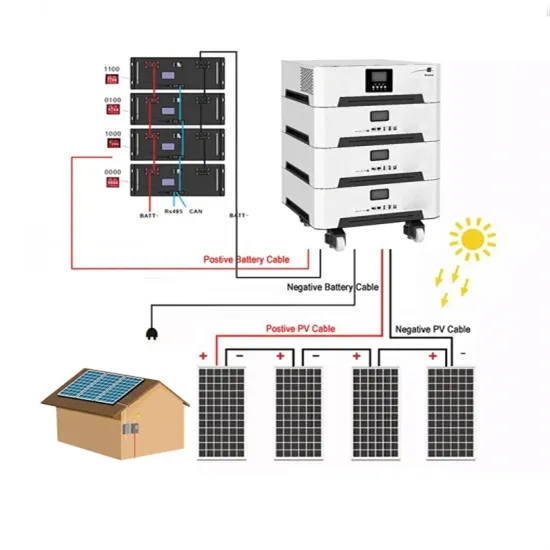

- Energy storage inverter and photovoltaic panels

- Do solar photovoltaic panels in Juba make money

- What is the wholesale price of photovoltaic panels in Tunisia

- Wholesale price of polysilicon photovoltaic panels

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.