Solar Glass Market Size, Trends, Growth Report, 2025-2033

Aug 14, 2025 · SOLAR GLASS MARKET SEGMENTATION By Type Based on type the solar glass market is classified as 3.2mm, 2.5mm, 2.0mm and others. By Application Based on

What s the Required Thickness for Photovoltaic Panel Glass

Why Photovoltaic Panel Glass Thickness Matters When designing solar panels, the glass thickness isn''t just a random choice—it''s a critical factor balancing durability, weight, and

Photovoltaic (PV) Glass Producers and Photovoltaic (PV) Glass

PV glass is an essential component of PV modules, and its production has increased rapidly in recent years. China has been the world''s largest producer and exporter of PV glass for many

What is the thickness of the double glass of photovoltaic

The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the

Production method of 2.5 mm photovoltaic module ultrathin

A photovoltaic module and coated glass technology, which is applied in glass tempering, glass manufacturing equipment, grinding/polishing equipment, etc., can solve the problem that

Top 10 Photovoltaic Glass (PV Glass) Supplier in

Apr 8, 2025 · Here is an overview of the top 10 photovoltaic glass suppliers in China for 2024. 1. XINYI SOLAR. Established: 2009. Location: Wuxi, China.

Something About Double-glass PV Modules, Transparent

Feb 17, 2025 · It is estimated that the original photovoltaic glass required for the production of 1GW 2.5mm double glass modules, 2.0mm double glass modules, and single glass modules is

How much glass is needed for terawatt-scale PV?

Sep 29, 2021 · "A fully double glass-based PV production will require amounts of float-glass exceeding today''s overall annual glass production of 84 Mt as early

Custom Anti-Reflection Texture Tempered Solar Photovoltaic Glass for PV

First Class raw glass sheets First Class raw glass sheets from Taiwan Glass, Xinyi Glass, JinJing Glass Our low-stock production management ensures that we use the freshest raw glass

全球太阳能发电用钢化玻璃市场的思考与预测(至2029年)

Sep 6, 2023 · 第15章世界太阳能发电钢化玻璃研究的主要发现 第16章附录 简介 目录 图表 The global Tempered Photovoltaic Glass market is projected to grow from US$ 9153.78 million in

Solar Glass Manufacturers in India | Solar Panel

Feb 23, 2025 · Elevate your solar panels with our anti-reflective coated solar glass. Connect with leading solar glass manufacturers in India for detailed

2.5mm Double Glass Photovoltaic Module Manufacturing

A double-glass photovoltaic and manufacturing method technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as

Ultra White Tempered Solar Glass 1.6mm 2mm 2.5mm

Ultra white tempered solar glass is widely used in solar power generation, solar panels, water heaters, greenhouses and other fields. As a professional glass manufacturer, our company

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Solar Glass & Mirrors Glass is used in photovoltaic modules as layer of protection against the elements. In thin-film technology, glass also serves as the substrate upon which the

Second Glass Loading & Placement Machine | Solar Panel Production

Jan 16, 2025 · A second glass loading and placement machine is a high-precision dual-glass panel making machine. The glass machinery features short cycle time, high positioning

Photovoltaic EVA Encapsulation Film Production Line

Apr 29, 2020 · The Most Comprehensive Selected Top Class Chinese Glass Machines, Products and Services Resource Glass Fabricating Machines | Glass Processing Machines | Glass

Market Projections for Glass For Building Integrated

Jun 24, 2025 · Glass For Building Integrated Photovoltaics by Application (Photovoltaic Roof, Photovoltaic Curtain Wall, Photovoltaic Lighting Roof, Others), by Types (2.5mm and

Contamination-Free Photovoltaic Quartz Glass for Solar Cell Production

What is Photovoltaic Quartz Glass? Photovoltaic Quartz Glass refers to high-purity quartz glass components specifically engineered for solar cell manufacturing processes. These specialized

INSTRUCTIONS FOR PREPARATION OF PAPERS

Jul 12, 2025 · remedy most of the reliability issues in PV module design. The traditional backsheet materials of conventional solar modules was replaced with toughened (heat strengthened) 2.5

Production line planning of some photovoltaic glass

Nov 12, 2021 · According to CPIA forecasts, the penetration rate of double glass will increase from 30% in 2020 to 60% by 2025; the thickness of 2.5mm/2.0mm in double glass is expected to be

6 FAQs about [Photovoltaic 2 5mm glass production]

What is Photovoltaic Glass?

At present, the mainstream product of photovoltaic glass is low-iron tempered patterned glass (also known as tempered suede glass) with a thickness of 3.2mm or 4mm.

How is Photovoltaic Glass made?

It is made by using a special embossing roller to press a special pyramid pattern on the surface of the ultra-white glass, as shown in Figure 1. At present, there are mainly the following two production processes for photovoltaic glass. (1) The production process of Gridfa glass was invented in 1961 by the Belgian Gravibel Manufacturing Company.

Who makes Photovoltaic Glass?

ACHT’s advanced technology, R&D system, and extensive corporate culture have solidified its position as a top photovoltaic glass manufacturer. Formerly known as Henan Anyang Color Picture Tube Glass Co., Ltd., the company has consistently focused on R&D, innovation, and the production of high-end glass. 6. Jinjing Group Co., Ltd. Established: 1904

Which type of glass is suitable for PV modules?

The commercial availability of 2mm thermally toughened ultra clear glass is an enabling tool for this route. Float glass as well as patterned glass with these properties is largely available along with a hermetic edge sealing, it is the choice for new PV modules. production for a glass-glass-module compared to a conventional glass-backsheet module.

Can a glass-glass-module make a solar photovoltaic module more eco-friendly?

A glass-glass-module based on thin toughened glass on the front and back of a solar photovoltaic module can have a dramatic impact on its environmental capabilities. Johann Weixlberger* and Markus Jandl** explain.

What makes Acht a top Photovoltaic Glass manufacturer?

The company is a prominent player in the photovoltaic glass market, offering ultra-clear rolled glass and TCO glass essential for solar energy applications. ACHT’s advanced technology, R&D system, and extensive corporate culture have solidified its position as a top photovoltaic glass manufacturer.

Update Information

- Latest news on photovoltaic glass mass production

- Photovoltaic glass production plant in Mauritania

- Production of photovoltaic glass panels

- Photovoltaic glass substrate production rate

- Second photovoltaic glass production in Podgorica

- Photovoltaic industry glass production stopped

- German environmentally friendly photovoltaic glass production

- Production of photovoltaic module glass

- The second largest photovoltaic glass

- Togo glass photovoltaic power generation enterprise

- Photovoltaic glass for 5G

- Roof photovoltaic glass

- Luxembourg photovoltaic transparent glass

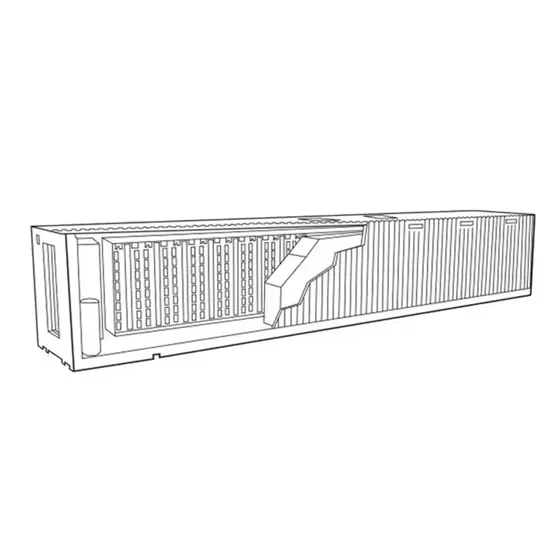

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.