Solar and Photovoltaic Panel Recycling: The Importance of Glass

Aug 18, 2025 · Recycling solar panels requires experience and highly specialized technologies capable of optimizing material recovery and ensuring maximum glass purity, which accounts

Solar photovoltaic recycling strategies

Mar 1, 2024 · First, this paper presents and analyzes the different policies surrounding PV recycling in different countries of the world. Secondly, it reviews existing recycling strategies of

Precise PV Separator Solar Panel Recycling Machine Photovoltaic

Precise PV Separator Solar Panel Recycling Machine Photovoltaic Panel Recycling Machine Solar Panel Crushing Sorting for Component Separation Our solar panel recycling plant is

Recent progress in silicon photovoltaic module recycling

Dec 1, 2022 · The rapid deployment of solar photovoltaic (PV) technology around the world brings the ineluctable problem of disposing of and recycling decommissioned solar photovoltaic

Recycling of solar photovoltaic panels: Techno-economic

Aug 20, 2022 · In recent decades, photovoltaic (PV) panels became a reliable solution to transform solar energy in electricity (Tao and Yu, 2015). Among PVs, the technology based on

Photovoltaic Glass Waste Recycling in the Development of Glass

Apr 3, 2023 · Abstract Because of the increasing demand for photovoltaic energy and the generation of end-of-life photovoltaic waste forecast, the feasibility to produce glass substrates

Full Auto PV Module Glass Silicone Frame Separation Plant

Key attributes type Recycling Plant Power 160 Kw core components motor, Engine, Other machinery test report Provided video outgoing-inspection Provided warranty 1.5 years material

Industrial PV Panel Glass Frame Junction Box Separation Line

Key attributes type Recycling Plant Power 160 Kw core components motor, Engine, Other machinery test report Provided video outgoing-inspection Provided warranty 1.5 years material

Methodological approaches for resource recovery from end

Jan 1, 2025 · In c-Si solar module recycling, the encapsulate polymer EVA, which is used to protect the PV cells, complicates the separation of backsheet, glass cover and the recovery

Photovoltaic panel solar panel glass removal machine

6 days ago · The solar de glassing machine is an efficient and environmentally friendly device mainly used to separate photovoltaic cells from photovoltaic glass. It is driven by solar or

Solar Panels Photovoltaic Panel Recycling Plant with Glass

In view of the current problems in the recycling of solar panel materials, we have developed a large-scale solar photovoltaic panel recycling equipment that is non-toxic, high in separation

Solar PV Panel Glass Removal Machine-Victor Machinery

Whole Glass Separation Process The photovoltaic glass panels enter the preheating plate via a conveyor belt. The panels are fixed by means of an upper pressure plate to prevent the panels

Photovoltaic panel solar panel glass removal machine

6 days ago · Solar de glassing machine is a device specifically designed to separate photovoltaic cells from glass backboards. Its working principle is based on the difference in thermal

Solar photovoltaic panel glass removal machine

The solar photovoltaic panel glass removal machine is a key equipment for the recycling and treatment of waste photovoltaic panels. It separates the glass layer on the photovoltaic panel

Glass separation process for recycling of solar photovoltaic

Nov 17, 2022 · Katayut Kamano, Chawannat Jaroenkhasemmeesuk, Chatchai Chaisartra, Thana Thoopkaew, Nakorn Tippayawong; Glass separation process for recycling of solar photovoltaic

Complete Solar Panel Recycling Plant: Your Sustainable Solution for PV

May 8, 2025 · Discover a complete solar panel recycling plant solution achieving 95%+ material recovery! Advanced pyrolysis, separation & refining tech for glass, silicon & metals.

Automatic PV Panel Glass Removal Silicone Cell Separation

Key attributes type Recycling Plant Power 160 Kw core components motor, Engine, Other machinery test report Provided video outgoing-inspection Provided warranty 1.5 years material

High Output Solar PV Panel Module Glass Frame Junction

Key attributes type Recycling Plant Power 160 Kw core components motor, Engine, Other machinery test report Provided video outgoing-inspection Provided warranty 1.5 years material

High-Purity Solar Panel Glass Recycling Machine PV Crushing

In view of the current problems in the recycling of solar panel materials, we have developed a large-scale solar photovoltaic panel recycling equipment that is non-toxic, high in separation

Photovoltaic Panel Glass Frame Junction Box Separation and

Key attributes type Recycling Plant Power 160 Kw core components motor, Engine, Other machinery test report Provided video outgoing-inspection Provided warranty 1.5 years material

6 FAQs about [Solar Photovoltaic Glass Separation Plant]

Does microwave heating affect the delamination of solar panels?

well as testing the effect of microwave heating on the delamination of the remaining pa nel. silicon PV panel. The findings revealed that the temperature had a significant impact on the separation of glass shards from the solar panel's EVA layer. Microwaves' dielectric heat property involved heating electrically

Is microwave a good option for delaminating PV panels?

After heating the PV panel with a microwave, the results showed that removing the glass pane could be conveniently conducted easier than a non-heated panel by about 50-60% of the force. In summary, the microwave frequency appeared to be an attractive option for delaminating expired or damaged PV panels.

How to delaminate solar panels?

Previous research showed many methods to delaminate solar panels. Still, some recommended that thermal practice such as radiofrequency heating is simple and has a low environmental impact and low operating costs. Unfortunately, it has a high installation cost and is hard to develop into commercialization.

How does microwave heating affect a solar panel?

approach allowed for easy separation of broken glass from the PV panel. As a result, significantly increasing the integrity of the solar cell. This will also allow for the thorough removal of all glass parts from the sample surface, as well as testing the effect of microwave heating on the delamination of the remaining pa nel. silicon PV panel.

How long will a solar PV panel last in Southeast Asia?

The project will be the most significant floating PV source in southeast Asia, having more than 1 million PV modules assembled. The approximate lifetime of a PV panel is about 25-30 years. Therefore, these solar PV wastes will be enormous at the end of life and may cause a big problem.

Can c-Si solar panels be recycled?

Electrothermal heating technology for recycling c-Si solar panels is currently being developed. The electrothermal technique, according to the study, would be able to restore glass and Si cells without causing harm. radiofrequency RF) electrothermal heating process. According to the high powered generators and RF electronic

Update Information

- Where is the solar photovoltaic plant for communication base stations located

- Solar panels at a Polish photovoltaic plant

- Photovoltaic glass production plant in Mauritania

- Photovoltaic and solar thermal glass

- Window type solar photovoltaic glass

- Seychelles Solar Photovoltaic Glass Manufacturer

- 2mm solar photovoltaic glass

- Georgia Photovoltaic Glass Processing Plant

- Dili Solar Panel Photovoltaic Power Plant

- Lebanon IoT Solar Photovoltaic Energy Storage Cabinet Site Charging

- Solar photovoltaic panels wind protection

- Huawei s photovoltaic glass brand in New York USA

- Solar photovoltaic panel 12 volt 60 amp

Solar Storage Container Market Growth

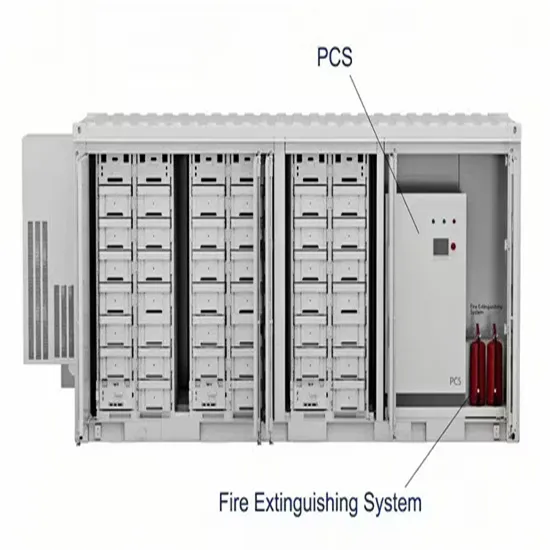

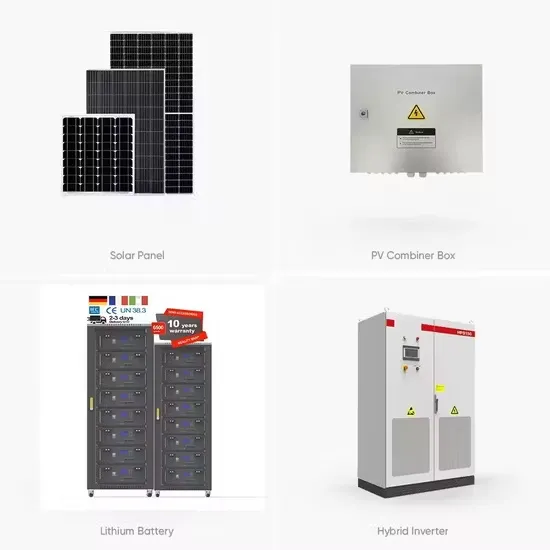

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.