Photovoltaic Glass Treatments: Clarifying Terminologies and

As a result, the tempering process fails, and the glass remains merely strengthened (heat-strengthened or semi-tempered) instead of fully tempered. Thin glass is also highly sensitive to

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · Weathering of float glass can be categorized into two stages: "Stage I": Ion-exchange (leaching) of mobile alkali and alkaline-earth cations with H+/H3O+, formation of

Anti-reflective Coated Glass for Photovoltaic Modules

Mar 3, 2025 · This standard specifies the terms and definitions, materials, requirements, test methods, inspection rules, marking, packaging, transportation and storage of anti-reflective

Photovoltaic pavement and solar road: A review and

Feb 1, 2023 · For the bottom protective layer, tempered glass, concrete floor, and resin and polymer substrate are all usual designs applied on the PV pavement (Table 3). Among those

Ultra-White Rolled Photovoltaic Tempered Glass Market

What are the key demand drivers for ultra-white rolled photovoltaic tempered glass in global solar panel manufacturing? The global demand for ultra-white rolled photovoltaic (PV) tempered

Photovoltaic glass panel transmittance standard

Where i 1 is the power generation efficiency of the PV panel at a temperature of T cell 1, t 1 is the combined transmittance of the PV glass and surface soiling, and t clean 1 is

Top 5: Factors Responsible for Glass Breakage in

Mar 13, 2025 · Using high-quality tempered glass with surface compression levels that meet or exceed industry standards can be one possible solution. As per

The Art of Moving Sunshine: A Step-by-Step Guide to Photovoltaic

Ever tried carrying a 50-pound glass sandwich across a construction site? That''s essentially what manual photovoltaic panel transportation feels like. As solar installations multiply faster than

6.8mm 7mm Transparent Solar PV Photovoltaic Glass

Jul 26, 2025 · Photovoltaic glass, also referred to as solar glass, is a specialized glass that integrates solar cells to convert sunlight into electricity. It combines the functionality of

Solar Photovoltaic Glass Panel Specifications

Photovoltaic (PV) glass is revolutionizing the solar panel industryby offering multifunctional properties that surpass conventional glass. This innovative material not only generates power

Glass & Glazing Codes and Standards for Architects

Oct 3, 2024 · National Glass Association NGA is a not-for-profit trade association, and the only national trade association serving the entire glass and glazing industry.

Lamination process and encapsulation materials for

May 21, 2024 · Recent developments of thin, 2mm tempered glass have made GG design a more competitive solution, compared with 3 or 4mm GG modules (heavyweight) or standard GBS

Ultra-thin PV Glass-Quantum Materials Technology (Suzhou)

The standard PV panel is made of a single layer tempered glass of 3.2mm thick, with a transparent or colored PET back sheet. The total thickness of module is between 4.5-5mm.

Photovoltaic glass: the perfect fusion between

Aug 18, 2025 · Photovoltaic glass is transparent solar panels designed to replace conventional glass in buildings and structures. These panels are capable of

Photovoltaic Glass Loading and Transportation Best

The answer lies in the fragile nature of photovoltaic (PV) glass – the backbone of solar energy systems. As global solar capacity grows at 15% annually (IRENA 2023), efficient photovoltaic

Photovoltaic Glass Treatments: Clarifying Terminologies and

Different treatments can enhance the mechanical performance of glass, particularly in terms of static load resistance (measured in Pascals) and hail resistance (as per IEC 61215,

NGA Presents Updated Resource on Glass Properties

Mar 28, 2025 · NGA has published an updated Glass Technical Paper (GTP), FB39-25 Glass Properties Pertaining to Photovoltaic Applications, which is available for free download in the

6 FAQs about [Photovoltaic tempered glass transportation standards]

Is this document applicable to building-integrated photovoltaics (BIPV) glass?

This publication was last reviewed and confirmed in 2023. Therefore this version remains current. This document specifies requirements of appearance, durability and safety, test methods and designation for laminated solar photovoltaic (PV) glass for use in buildings. This document is applicable to building-integrated photovoltaics (BIPV).

How does GG design affect PV module reliability?

This decrease in water vapour ingress has a direct positive impact on PV module reliability compared with that for a standard GBS lay-up. Recent developments of thin, 2mm tempered glass have made GG design a more competitive solution, compared with 3 or 4mm GG modules (heavyweight) or standard GBS modules.

Do GG PV modules perform a thermal-cycling test?

GG PV modules (incorporating HJT cells) with SWCT and TPO encapsulant (TPO1 in Table 1) also achieve successful results in extended thermal-cycling tests (TC: –40°C/+85°C), with a power output degradation of only 2.5% after 800 cycles (eight times the IEC standard) (see Table 4). Table 3.

Why do we need a long-term reliability of PV modules?

In the last few years PV technology has seen continuous improvements, with significant enhancements at the cell and module levels. In addition to the requirement of high efficiency, the long-term reliability of PV modules leads to proposals for innovative module concepts and designs.

Are thermoplastic polyolefin encapsulants a good choice for long-lasting PV modules?

Thermoplastic polyolefin encapsulants with water absorption less than 0.1% and no (or few) cross-linking additives have proved to be the best option for long-lasting PV modules in a glass-glass (GG) configuration.

How are PV modules laminated?

The lamination of PV modules is most frequently carried out using a vacuum-membrane laminator with a single heating plate (Fig. 5) and a typical process based on three main steps .

Update Information

- Photovoltaic glass factory tempered price

- EK Photovoltaic Glass Transportation

- How much does a photovoltaic tempered glass cost

- Tempered glass photovoltaic sun room

- Photovoltaic glass transportation damage

- Tempered glass photovoltaic glass

- Malta double glass photovoltaic curtain wall customization

- Five things to look at and three things to determine about photovoltaic glass

- Tripoli double glass photovoltaic curtain wall supplier

- Are there any photovoltaic glass manufacturers in Cape Verde

- Photovoltaic glass component companies

- Photovoltaic curtain wall glass supplier

- Cadmium ion photovoltaic glass

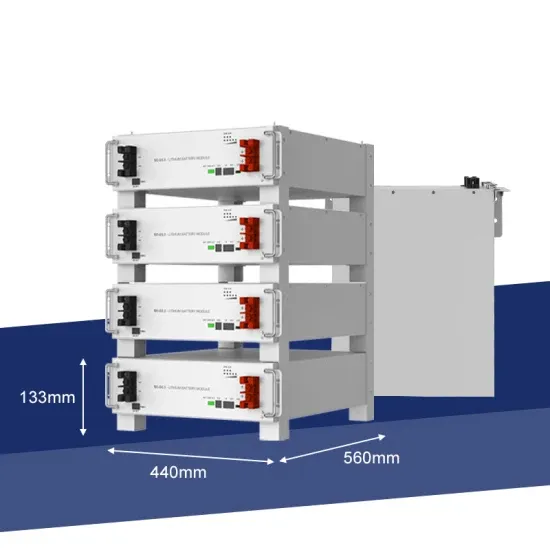

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.