High Gain DC–AC High-Frequency Link Inverter With Improved

Feb 25, 2021 · This article presents a high gain pure sine- wave inverter based on the full-bridge dc–ac high-frequency link cycloconverter topology for telecom or general-purpose

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility-supplied

MIT Open Access Articles A High Frequency Inverter for

Oct 1, 2022 · zero voltage switching needed for high efficiency operation at high frequency. While an inverter can be inductively preloaded to provide the needed inductive load current for zero

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · This application report documents the implementation of the Voltage Fed Full Bridge isolated DC-DC converter followed by the Full-Bridge DC-AC converter using TMS320F28069

What are Low Frequency Toroidal Inverters?

Apr 6, 2022 · So here I heard some inverters that are "low frequency toroidal inverters". 1. What are they? Example? 2. What is their advantage vs regular

High-Frequency Inverters: From Photovoltaic, Wind, and

Jul 26, 2022 · dc–ac converter 29 High-Frequency Inverters, the HF transformer is incorporated into the integrated structure. In the subsequent sections, based on HF architectures, we

Inverter design using high frequency

Feb 27, 2021 · In which we are developing an inverter which is to be light in weight, compact and highly energy efficient. This can possible with the help of High Frequency Inverter; hence we

How to Reduce Electromagnetic Interference in Inverters

However, the process of reducing THD by choosing high switching frequency results in the generation of electromagnetic interference in the inverter. EMI From the Hard Switching of

Inverter design using high frequency

Oct 31, 2023 · ABSTRACT In this paper we are developing inverter which is very cheap in cost and portable we are using 50KHz frequency for DC Technique and output 250V DC, 500mA,

A High-Frequency Inverter for Variable-Load Operation

Jan 18, 2019 · This paper presents a new inverter architecture suitable for driving widely varying load impedances at high frequency (HF, 3-30 MHz) and above. We present the underlying

High Frequency Inverter Using Power MOSFET

2.Square-Wave applications is high frequency Inverter oscillator which plays Ci cuit a central role in ultrasonic generators, induction InFig. 1, the tested square-wave voltage-fed bridge heating,

Pure Sine Wave Inverters

Aug 16, 2025 · While an inverter can produce different waveforms, a pure sine wave output is preferable because many electrical products are designed to work best with a sine wave AC

Advanced power inverter topologies and modulation

Apr 1, 2021 · Such drive systems are usually fed by semiconductor switch-based inverters, which, unlike balanced pure sine-wave AC sources, produce large-amplitude, high-frequency

High-Frequency Electromagnetic Vibration Analysis and

Dec 23, 2024 · The utilization of inverters and pulse width modulation (PWM) technology in driving permanent magnet synchronous motors (PMSMs) introduces high-frequency sideba

In-depth analysis of Electromagnetic interference of frequency

Airborne radiation mode: The PWM voltage transmitted on the output cable of the inverter contains rich high-frequency components, which will produce electromagnetic wave radiation

Monrovia inverter pure sine wave

Pure sine wave inverter 12V to 240V for sale, output frequency 50Hz or 60Hz for selection, output AC 110V, 100V, 220V, 230V and 240V are optional. 500 watt pure sine wave inverter allows to

Adaptive switching frequency PWM method of SiC inverters

Dec 11, 2024 · Electromagnetic interference (EMI) noise resulting from the high-frequency harmonics in voltage source inverters (VSIs) poses a significant challenge in power electronics

6 FAQs about [Monrovia electromagnetic wave high frequency inverter]

How do high frequency inverters produce a sine wave output?

To produce a sine wave output, high-frequency inverters are used. These inverters use the pulse-width modification method: switching currents at high frequency, and for variable periods of time. For example, very narrow (short) pulses simulate a low voltage situation, and wide (long pulses) simulate high voltage.

What is the difference between low frequency and high frequency inverters?

The low frequency inverters typically operate at ~60 Hz frequency. To produce a sine wave output, high-frequency inverters are used. These inverters use the pulse-width modification method: switching currents at high frequency, and for variable periods of time.

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

What is a high frequency variable load inverter?

ut Pmax VINmax13:56MHz21:31kW375VIV. CONTROL SCHEMEA. Control ChallengesIn Section II the high frequency variable load inverter was modeled with each constituent inverter as an ideal voltage source that could drive any resistiv / inductive load, only sub-ject to maximum output voltage and current limits. However, real inverters h

What is a modified square wave inverter?

The Modified Square Wave also known as the Modified Sine Wave Inverter produces square waves with some dead spots between positive and negative half-cycles at the output. The cleanest utility supply like power source is provided by Pure Sine Wave inverters.

Can a low frequency waveform control be used in an inverter?

To produce a modified square wave output, such as the one shown in the center of Figure 11.2, low frequency waveform control can be used in the inverter. This feature allows adjusting the duration of the alternating square pulses.

Update Information

- Is a pure wave inverter a high frequency

- High frequency inverter can use half wave

- High frequency inverter produces sine wave

- Inverter has good high frequency and good low frequency

- High frequency inverter modification

- The best brand of high frequency inverter

- Which is better high frequency or low frequency inverter

- High frequency inverter field

- High frequency inverter input voltage

- South Sudan High Frequency Communication Inverter

- Sophia high frequency inverter manufacturer

- Which brand should I choose for high frequency inverter

- Huawei high frequency inverter efficiency

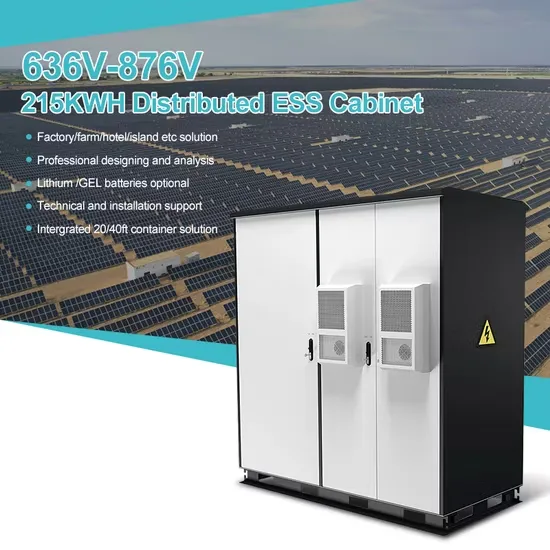

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.