High-frequency-link micro-inverter with front-end current-fed half

Nov 13, 2013 · A high-frequency-link micro-inverter is proposed for integrating a single photovoltaic panel to a local load or utility grid. The number of power switches is minimized in

High-efficiency inverter for photovoltaic applications | IEEE

Nov 1, 2010 · The topology is based on a series resonant inverter, a high frequency transformer, and a novel half-wave cycloconverter. Zero-voltage switching is used to achieve an average

Half-Wave Cycloconverter-Based Photovoltaic

May 29, 2019 · A high-frequency transformer and a series-resonant tank are used to interface the full-bridge inverter to the half-wave cycloconverter. All power switches are switched with zero

Power Frequency Inverter vs. High Frequency

May 15, 2024 · In the field of power electronics and energy conversion, inverters, as key equipment for power conversion, play a vital role. Inverters are capable

Design and Development of High Frequency Inverter for

In these applications, the optimal converter design is essential for handling the high power and frequency operation. In this paper, Simulation & Hardware development of High frequency

Solar Micro-Inverter with Phase Shift Power Modulation and Half Wave

Feb 17, 2022 · Main components here are a series resonant inverter with full-bridge, a high-frequency transformer, and a half-wave cyclo-converter. A micro inverter configuration

High-Frequency Inverters: From Photovoltaic, Wind, and

Jul 26, 2022 · FIGURE 29.24 Key waveforms [13] of the primary-side dc–ac converter in one cycle and enlarged view of the interval between two dot lines; (a) three-phase sine-wave references

Inverter design using high frequency

Feb 27, 2021 · In which we are developing an inverter which is to be light in weight, compact and highly energy efficient. This can possible with the help of High Frequency Inverter; hence we

High-frequency-link micro-inverter with front-end current-fed half

Nov 13, 2013 · A high-frequency-link micro-inverter is proposed for integrating a single photovoltaic panel to a local load or utility grid. The number of power switches is mi

Understanding High-Frequency Inverters

6 days ago · In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to

Half-Wave Cycloconverter Based PV Micro-inverter

Dec 27, 2017 · A high-frequency transformer and a series-resonant tank circuit is used to interface the full-bridge inverter to the half-wave cyclo-converter. All power switches are switched with

Understanding inverter frequency – effects and

Oct 1, 2024 · Understanding inverter frequency – effects and adjustments In today''s world, inverters play a vital role in various applications, such as home

H-Bridge Sine Wave Inverter Circuit using Arduino

May 24, 2025 · In this article I will explain how we can build an Arduino-controlled H-Bridge sine wave inverter circuit using some easy parts. So this thing will basically convert DC into AC but

A High Frequency Isolated DC-AC Converter using Dual

Mar 27, 2021 · I. Introduction High-frequency ac-link-based architectures represent another category of single-stage isolated topologies and can be further classified into two types. In the

Half-Wave Cycloconverter Based PV Micro-inverter

Dec 27, 2017 · Abstract: In this paper, a grid-connected micro inverter with a less number of power conversion stages and fewer passive components is proposed. A high-frequency

(PDF) A bidirectional, sinusoidal, high-frequency

Aug 1, 2001 · A new method for the design of a bidirectional inverter based on the sinusoidal pulse-width modulation principle and the use of a low-cost and

H Bridge Inverter Circuit using IC SG3525 and

Jan 9, 2025 · The SG3525-based H-Bridge inverter circuit converts low-voltage DC into high-voltage AC, making it ideal for use in applications like renewable

Detailed explanation of a high-frequency output asymmetric half

Jun 21, 2014 · Figure 2 shows the key waveform of a high-frequency output asymmetric half-bridge inverter. The asymmetric half-bridge inverter can be divided into 6 different working

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an

6 FAQs about [High frequency inverter can use half wave]

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

What is a half-wave cycloconverter?

A half-wave cycloconverter is used to integrate the microinverter to the grid at the secondary side. By using a half-wave cyclo-converter, the number of switches in the secondary side can be reduced by half compared to a full-wave cycloconverter. This is expected to result in reduced switching and conduction losses in the overall inverter.

What are the disadvantages of a microinverter with full-bridge inverter and half-wave cycloconverter?

A microinverter with full-bridge inverter and a half-wave cycloconverter is proposed in . Frequency modulation is used as the power control method of this inverter. Hence, it has some drawbacks such as a wide and unpredictable noise spectrum, more complex filtering of the output voltage ripple, and poor utilization of magnetic components .

What is the difference between a half-bridge and a full-bridge inverter?

The full-bridge inverter is used as the primary-side inverter of the microinverter due to its higher voltage gain compared to the half-bridge inverter, although the number of switches in the full-bridge circuit is twice that of the half-bridge.

Why are full-bridge inverter and half-wave cycloconverter topologies selected?

Full-bridge inverter and half-wave cycloconverter topologies are selected because together they reduce the required transformer turns ratio (e.g., as compared to using a half-bridge inverter or a full-wave cycloconverter), thus improving achievable efficiency.

What is soft-switching operation of a full-bridge half-wave cycloconverter?

The soft-switching operation of the full-bridge half-wave cycloconverter is analyzed using the derived resonant current equation for the three stepped full-bridge output voltage and the half-wave cycloconverter input voltage.

Update Information

- Monrovia electromagnetic wave high frequency inverter

- High frequency inverter produces sine wave

- Is a pure wave inverter a high frequency

- 300k high frequency inverter

- Customized high frequency inverter

- Israel high frequency inverter

- High frequency inverter input voltage

- High frequency inverter field

- Lisbon high frequency inverter price

- Which is better high frequency or low frequency inverter

- Rack-mounted inverter high frequency

- The best brand of high frequency inverter

- Sri Lanka High Frequency Power Inverter

Solar Storage Container Market Growth

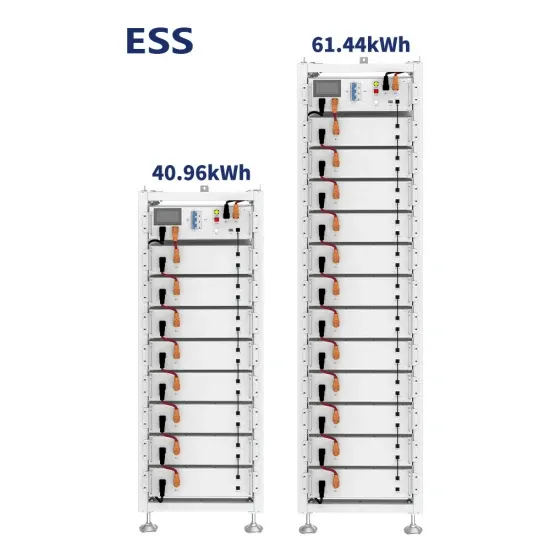

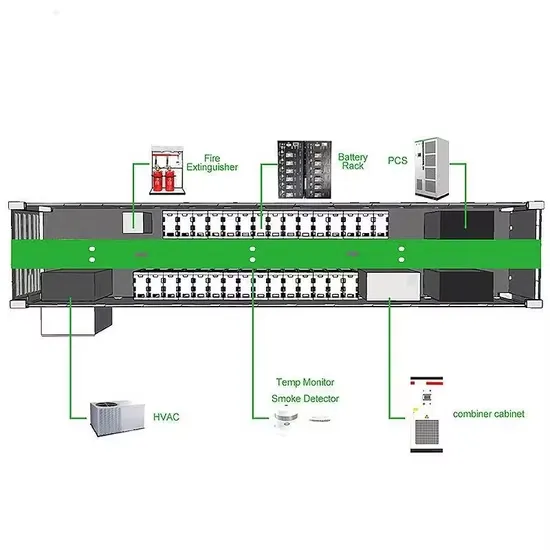

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

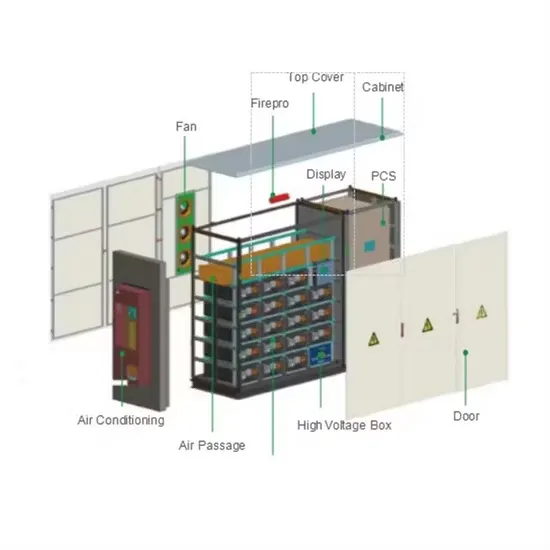

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.