High-Frequency Inverters: From Photovoltaic, Wind, and

Jul 26, 2022 · dc–ac converter 29 High-Frequency Inverters, the HF transformer is incorporated into the integrated structure. In the subsequent sections, based on HF architectures, we

High Frequency Inverter vs low Frequency Inverter

Conclusion In conclusion, the choice between high-frequency and low-frequency inverters depends largely on the specific needs of the application. High-frequency inverters offer the

High-Frequency Variable Load Inverter Architecture

Jun 4, 2025 · The invented high-frequency inverter system enables HF power delivery directly into highly variable impedance loads with a relatively high efficiency. A pair of inverters are coupled

High-Frequency Inverters: From Photovoltaic, Wind, and

Jul 26, 2022 · pave way for isolated high-power and HFL inverters. They have attained significant attention with regard to wide applications encompassing high-power renewable- and

High Frequency Power Inverters: A Guide To Modern Solutions

May 4, 2024 · High frequency power inverters have revolutionized the field of electrical conversion, enabling efficient and reliable power supply solutions for various applications. In

Comprehensive Diagnostic Assessment of Inverter Failures in

High-frequency conducted emissions are measured using a high-voltage probe (HVP), current clamp (CC), and EMI receiver (EMIR), enabling detailed analysis of transient and

HIGH FREQUENCY INVERTER FOR MULTI

Mar 15, 2018 · This paper proposes the control of high frequency resonating inverter for multi-coil induction heating. The Full bridge voltage source inverter is operated at high frequency to

Advanced power inverter topologies and modulation

Apr 1, 2021 · The demand for more reliable and efficient electric machines and drives is constantly growing in the renewable energy and transport electrification sectors. Such drive systems are

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an

High Frequency Power Inverters: A Guide To Modern Solutions

May 4, 2024 · High frequency power inverters, also known as HFPI, are devices that convert direct current (DC) into alternating current (AC) at a higher frequency than traditional power

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · If you are looking for an inverter for fixed power stations, precision instruments, or other related fields, then go with power-frequency inverters. However, a high-frequency

High-Frequency Inverters: From Photovoltaic, Wind, and

Jan 1, 2011 · A high-power high-frequency and scalable multi-megawatt fuel-cell inverter for power quality and distributed generation, IEEE Power Electronics, Drives, and Energy Systems Conf.,

High Frequency Inverter defined | AMADA WELD TECH

4 days ago · High Frequency Inverter welders use submillisecond pulsewidth modulation (switching) technology with closed-loop feedback to control the weld energy in submillisecond

High-Frequency Characterization of Space Vector Pulse

Apr 28, 2024 · Silicon carbide (SiC) high-frequency three-phase inverters are gaining increasing attention in the field of power electronics due to the growing demand for efficient energy

HIGH VS LOW FREQUENCY INVERTERS

Nov 28, 2022 · Low-frequency inverters have the advantage over high-frequency inverters in two fields: peak power capacity, and reliability. Low-frequency inverters are designed to deal with

Review on Silicon Carbide based High-Fundamental

Jun 21, 2025 · Recent research and development efforts in SiC inverters for electric drive applications highlight a strong focus on achieving high power density, high efficiency, and high

(PDF) Review on Silicon Carbide based High-Fundamental Frequency

Jan 1, 2025 · This article provides a comprehensive review of Silicon Carbide (SiC) based inverters designed for High-Speed (HS) drive applications, which require higher output

High-frequency inverter technology: the next leap forward

Feb 28, 2025 · As a key technology in the field of solar inverters, high-frequency inverter technology has the advantages of high efficiency, small size, light weight, high power density,

Using High-Control-Bandwidth FPGA and SiC Inverters to Enhance High

Jul 20, 2018 · A high-frequency injection (HFI) sensorless control for interior permanent magnet synchronous motors with enhanced precision and widened speed range is proposed in this

Inverter design using high frequency

Feb 27, 2021 · In which we are developing an inverter which is to be light in weight, compact and highly energy efficient. This can possible with the help of High Frequency Inverter; hence we

Review of very high frequency power converters

Jul 1, 2020 · The matching networks are added between the inverter stages and rectifier stages to adjust the equivalent impedance of the rectifier stage. Fig. 4

6 FAQs about [High frequency inverter field]

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

What are common high-frequency inverter circuit configurations?

Common high-frequency inverter circuit configurations include: Key design factors for high-frequency inverters: Switching frequency – Higher frequency allows smaller filter components but increases losses. Optimize based on tradeoffs. Filter components – Smaller inductors and capacitors possible at high frequencies. Balance size versus performance.

What are the advantages and disadvantages of high frequency inverters?

Benefits of High-Frequency Inverters: Uncover the advantages offered by high-frequency operation, such as reduced size, improved efficiency, and noise suppression. Topologies of High-Frequency Inverters: Examine the different topologies used in high-frequency inverters, including half-bridge, full-bridge, and multilevel.

What are the topologies of high-frequency inverters?

Topologies of High-Frequency Inverters: Examine the different topologies used in high-frequency inverters, including half-bridge, full-bridge, and multilevel. Modulation Techniques: Discover various modulation techniques employed in high-frequency inverters to control the output AC waveform.

What determines the output frequency of a high-frequency inverter?

The output frequency depends on how fast the switches cycle on and off. Common high-frequency inverter circuit configurations include: Key design factors for high-frequency inverters: Switching frequency – Higher frequency allows smaller filter components but increases losses. Optimize based on tradeoffs.

How do high-frequency inverters work?

These enigmatic devices possess the uncanny ability to transform direct current (DC) into alternating current (AC) at remarkably high frequencies, unlocking a world of boundless possibilities. This comprehensive guide embarks on a quest to unravel the intricacies of high-frequency inverters, peeling back their layers to reveal their inner workings.

Update Information

- High frequency inverter input voltage

- High frequency inverter converted to water cooling

- Tripoli high frequency inverter price

- Huawei high frequency inverter efficiency

- Which is better high frequency or low frequency inverter

- How much does a high frequency inverter cost in Colon Panama

- High frequency inverter produces sine wave

- High frequency inverter to charge lithium battery

- Sri Lanka High Frequency Power Inverter

- Sea Island 2025 Type A High Frequency Inverter

- 800w high frequency inverter

- 300k high frequency inverter

- What is a high frequency pwm inverter

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

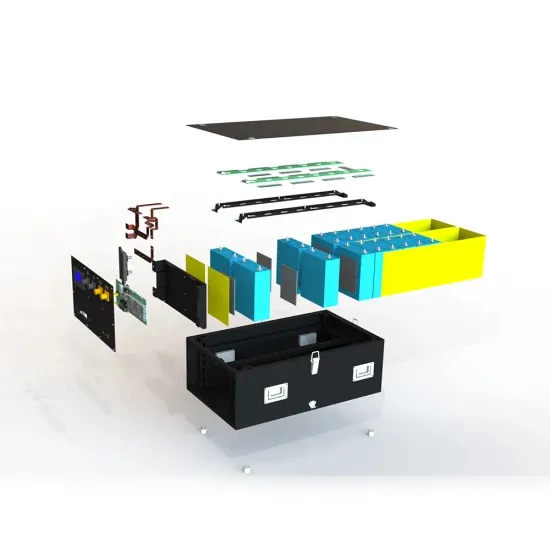

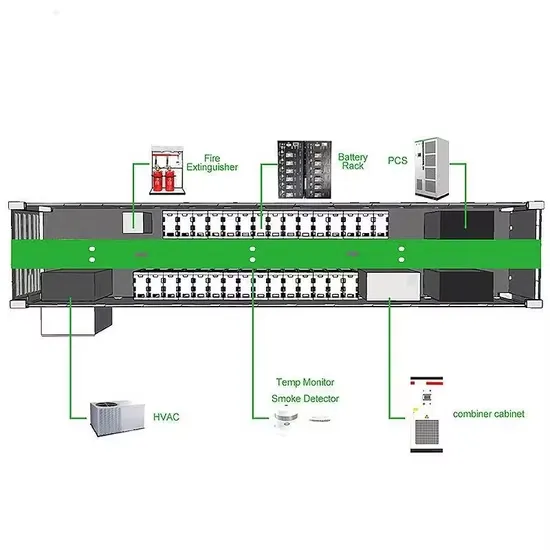

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.