800VA Pure Sine Wave Inverter''s Reference Design (Rev

Jan 10, 2025 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility

Is there an easy way to tell if a unit is pure sine wave vs modified

Oct 21, 2019 · Plug a box fan or osculating fan into it. If it''s a modified Sine Wave, it will usually hum and not be as strong (RPM''s) compared to plugging it into utility power. Compare the

High Gain DC–AC High-Frequency Link Inverter With Improved

Feb 25, 2021 · Abstract: This article presents a high gain pure sine- wave inverter based on the full-bridge dc–ac high-frequency link cycloconverter topology for telecom or general-purpose

ADVANTAGES OF PURE SINE WAVE INVERTERS OVER

Mar 20, 2020 · The high frequency harmonic content in a modified sine wave produces enhanced radio interference, higher heating effect in motors / microwaves and produces overloading due

A highly efficient single-phase sine-wave inverter with single

Jul 18, 2017 · This paper presents a highly efficient single-phase sine-wave inverter with single-switch high-frequency modulation. In this topology, a control circuit is connected at the lower

A bidirectional, sinusoidal, high-frequency inverter

Oct 29, 2015 · The lowpass filter output is a high-level direct volt- age that is converted into a low-frequency wave by an SPWM inverter. In an alternative version, the HF bridge inverter

How does the inverter works ? – PCB HERO

Mar 5, 2025 · 2. Key Components of an Inverter DC Input Source: Provides the DC power to be converted (e.g., 12V, 24V, or 48V battery). Oscillator Circuit: Generates a high-frequency AC

What is a Pure Sine Wave Inverter? | inverter

Apr 14, 2022 · The pure sine wave inverter is a device that can invert the DC power of the battery into a sine wave AC power with a rated voltage output for

⚡ What is a Pure Sine Wave Inverter and Why Does it Matter?

Jun 10, 2025 · Electricity that comes from the power grid is in the form of a sine wave—a smooth, repeating wave that maintains a consistent frequency (usually 50 or 60 Hz). A pure sine wave

Design your own Sine Wave Inverter Circuit from

Dec 19, 2024 · In this article I have explained comprehensively regarding how to design a sine wave inverter without any form of coding or complex circuit

high-frequency power inverter: high-frequency sine wave inverter

Jul 20, 2020 · The high-frequency power inverter uses a low-frequency sine wave in combination with a high-frequency DC signal so that when one is combined with the other, the two waves

Inverter Types & Working Principle | Sine Wave,

2 days ago · The article provides an overview of inverter technology, explaining how inverters convert DC to AC power and detailing the different types of

Everything You Need to Know About Inverters

Modified Sine Wave Inverter: Produces a stepped waveform that approximates a sine wave. It is more efficient than a square wave inverter and works well with most electronics, but may

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility-supplied

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · ABSTRACT The High-Frequency Inverter is mainly used today in uninterruptible power supply systems, AC motor drives, induction heating and renewable energy source

Pure Sine Wave Inverter: A Comprehensive Guide to

Oct 9, 2023 · 4. Technical Working of Pure Sine Wave Inverters: Pure sine wave inverters employ advanced circuitry and digital signal processing techniques to achieve a smooth and precise

6 FAQs about [High frequency inverter produces sine wave]

How do high frequency inverters produce a sine wave output?

To produce a sine wave output, high-frequency inverters are used. These inverters use the pulse-width modification method: switching currents at high frequency, and for variable periods of time. For example, very narrow (short) pulses simulate a low voltage situation, and wide (long pulses) simulate high voltage.

What type of inverter is used to produce a sine wave?

Also, transformers are used here to vary the output voltage. Combination of pulses of different length and voltage results in a multi-stepped modified square wave, which closely matches the sine wave shape. The low frequency inverters typically operate at ~60 Hz frequency. To produce a sine wave output, high-frequency inverters are used.

How does a pure sine wave inverter work?

DC Power Input: The pure sine wave inverter is connected to a DC power source, such as a battery or a DC power supply. Pulse Width Modulation (PWM): The DC power is converted into a high-frequency AC signal using Pulse Width Modulation (PWM).

What is the difference between low frequency and high frequency inverters?

The low frequency inverters typically operate at ~60 Hz frequency. To produce a sine wave output, high-frequency inverters are used. These inverters use the pulse-width modification method: switching currents at high frequency, and for variable periods of time.

What is a modified sine wave inverter?

Modified sine wave inverters and pure sine wave inverters are two types of power inverters. The main difference between them lies in the quality and characteristics of the AC waveform they produce.

Is a pure sine wave inverter worth it?

Yes. A pure sine wave inverter is indeed worth it and a necessity, especially in homes or line of work that utilizes devices or power outlet that has a direct current waveform. Does a Fridge Need Pure Sine Wave?

Update Information

- Branded industrial frequency pure sine wave inverter

- Production of sine wave power frequency inverter

- High frequency inverter can use half wave

- Juba Sine Wave Inverter BESS Company

- Sine wave inverter source manufacturer

- Korean high frequency inverter installation

- Sophia high frequency inverter manufacturer

- Mongolia pure sine wave inverter manufacturer

- 8000w post-stage sine wave inverter

- Port Vila Pure Sine Wave Inverter

- Sine wave clipping occurs in the inverter

- 5kW high frequency inverter

- 30w sine wave inverter

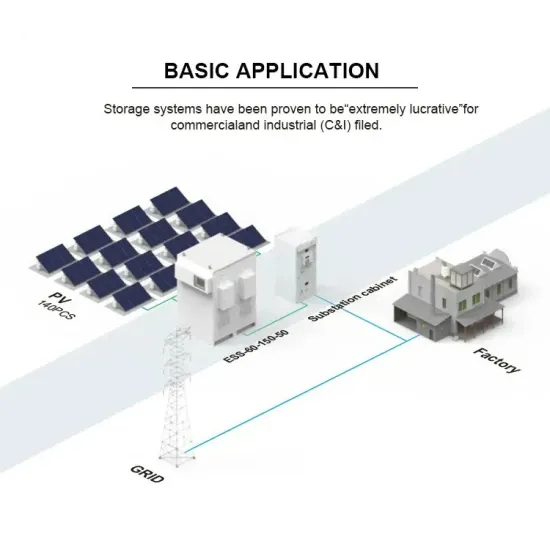

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.