Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Lithium battery Production Process – Prominer (Shanghai)

Mar 26, 2025 · The production goal of the latter process is to complete formation and encapsulation. By the middle process, the functional structure of lithium battery cell has been

Lithium-Ion Battery Assembly Process & Key Stages

May 17, 2025 · The lithium-ion battery assembly process is a sophisticated, multi-layered operation that relies heavily on precision, quality, and cutting-edge technology. With growing

Introduction to the manufacturing process of

Aug 1, 2024 · The composition of lithium-ion batteries is relatively complex, mainly including cathod, anode, separators, electrolytes, current collectors, binders,

Process flow diagram for square lithium-ion battery

To enhance product quality and operational safety of lithium-ion batteries, this paper proposes a risk analysis method based on an optimized Failure Modes and Effects Analysis (FMEA).

Square lithium battery assembly method

lithium battery pack assembly process. At every stage, inline testing and inspection stations meticulously verify the integrity of the cell connections, ensuring that each weld or bolt meets

Square lithium battery assembly method

assembly. forming, agi A lithium battery comprises an aluminum shell, a roll core assembly arranged in the aluminum shell, and a positive electrode integrated assembly and a negative

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Diferent shapes of the lithium-ion cell Nomenclature of lithium-ion cell/battery Overview of Li-ion battery packs Assembling Process Detailed flowchart for Li-ion battery pack

Stacking or Winding — Which technology is best

Sep 5, 2024 · In the assembly process of lithium-ion battery cells, there are mainly two techniques: winding and Stacking. The establishment of these two

Assembling method of square winding type lithium ion battery

A lithium-ion battery and assembly method technology, which is applied to secondary batteries, secondary battery manufacturing, battery pack components, etc., can solve the problems of

The basic structure of the square battery

Sep 19, 2019 · Square battery capacity big, relatively easier cylindrical batteries, in the process of ascension capacity, less restricted.But with the increase of

Detailed production process of lithium battery square shell

At the heart of the battery industry lies an essential lithium ion battery assembly process called battery pack production. In this article, we will explore the world of battery packs, including

The Manufacturing Process of Lithium-Ion Batteries

Lithium-ion batteries have revolutionized the way we power our portable electronic devices and are increasingly being used in electric vehicles and renewable energy storage systems. The

Square, Cylindrical, Soft Pack: Analysis of Manufacturing

Jul 14, 2025 · Shell Manufacturing: The outer casing of square lithium batteries is typically made from metal materials, such as aluminum alloys or stainless steel. The manufacturing process

Introduction to the manufacturing process of

Aug 1, 2024 · According to the core package forming form, it can be divided into square batteries, cylindrical batteries and soft-pack batteries. Conventionally,

Process flow diagram of square lithium-ion battery assembly

Download scientific diagram | Process flow diagram of square lithium-ion battery assembly workshop. from publication: A risk analysis method for potential failure modes in the lithium-ion

The Intricate Journey of Lithium Battery Assembly: A Detailed Process

Sep 13, 2024 · Layers of anode, separator, and cathode are meticulously stacked or rolled together, forming the battery cell. This assembly process demands precision, as improper

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Conclusion The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each

Detailed production process of lithium battery square shell

How are lithium ion battery cells manufactured? The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell

6 FAQs about [Assembly process of square lithium battery]

How are lithium ion battery cells manufactured?

The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode manufacturing and cell finishing process steps are largely independent of the cell type, while cell assembly distinguishes between pouch and cylindrical cells as well as prismatic cells.

What is lithium ion battery assembly process?

During charging, lithium ions migrate to the negative electrode; during discharge, they return to the positive side, producing electrical energy. The lithium-ion battery assembly process can be categorized into three key stages: 1. Front-End: Electrode Manufacturing

What are the three stages of lithium-ion battery assembly?

The lithium-ion battery assembly process can be categorized into three key stages: 1. Front-End: Electrode Manufacturing This initial phase focuses on producing high-performance electrodes, a critical step in the battery cell-making machine workflow.

How does a lithium ion battery work?

The battery works through the reversible movement of lithium ions between electrodes. During charging, lithium ions migrate to the negative electrode; during discharge, they return to the positive side, producing electrical energy. The lithium-ion battery assembly process can be categorized into three key stages: 1.

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the transferability of competencies from the production of lithium-ion battery cells is discussed. The publication “Battery Module and Pack Assembly Process” provides a comprehensive process overview for the production of battery modules and packs.

How does a lithium battery pack work?

Packaging: Assembled cells move into the lithium battery pack assembly stage, where they are configured into packs, enclosed, and prepared for shipment. Quality Control: Every step, from mixing to testing, demands extreme precision. Safety: Mishandling materials or processes can result in thermal runaways or fire hazards.

Update Information

- Cylindrical lithium battery assembly process

- Lithium battery assembly cylindrical

- Quick assembly of lithium battery pack

- Micronesia lithium battery assembly outdoor power supply

- Belgian square lithium battery size specifications

- 12v energy storage lithium battery assembly

- Guinea standard square lithium battery

- Cylindrical lithium battery and square

- 21v lithium battery cross section square

- New Zealand high voltage energy storage lithium battery assembly

- Canadian power lithium battery processing plant

- Juba lithium battery energy storage solution

- 6v200a lithium battery pack price

Solar Storage Container Market Growth

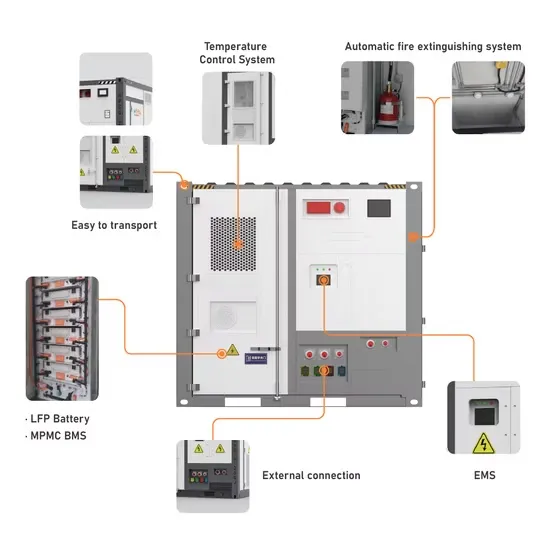

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.