Calculate the number of series and parallel connections for lithium

May 19, 2024 · Series parallel connection of lithium batteries is particularly common in some PACK factories. Generally, lithium battery packs are composed of batteries in series parallel

How Many Lithium Cells Are Needed to Create a 12V Battery

Feb 22, 2025 · To create a 12V lithium battery, 3-4 lithium cells are typically connected in series. Lithium-ion cells have a nominal voltage of 3.2V (LiFePO4) or 3.7V (NMC). Using four

How Many Lithium Cells for 48V? Lithium Cells for 48V

Aug 9, 2024 · How many lithium cells are needed to create a 48V battery? To build a 48V battery, you need to connect lithium cells in series so that their voltages add up to approximately 48

Lithium Series, Parallel and Series and Parallel

Mar 23, 2021 · Introduction Lithium battery banks using batteries with built-in Battery Management Systems (BMS) are created by connecting two or more batteries together to support a single

How to Wire 12V Batteries in Series & Parallel

Feb 10, 2023 · Learn how to wire batteries in series, parallel, and series-parallel with our step-by-step tutorial. Increase your battery voltage and amp hour

Connecting batteries in parallel – BatteryGuy

May 3, 2024 · The battery with the higher voltage will attempt to charge the battery with the lower voltage to create a balance in the circuit. primary (disposable) batteries – they are not

Charging LiFePO4 Batteries In Parallel And Series

Oct 7, 2023 · In conclusion, you must have got all the information around lithium batteries and charging lithium phosphate batteries in parallel and series. While

Calculate Battery Size For Any Size Inverter

Mar 3, 2023 · Related Post: Solar Panel Calculator For Battery How To Calculate Battery Capacity For Inverter To calculate the battery capacity for your inverter

How many strings of 24v lithium battery packs should I use

The ternary lithium standard stipulates that the voltage is 3.7v, full of 4.2v, three strings are 12v, and 48v must have four three strings, but the lead-acid battery of electric vehicles

How Many Cells in a 24 Volt Battery? Lead-Acid vs. Lithium Battery

Mar 14, 2025 · In summary, a typical 24-volt battery configuration requires 12 lead-acid cells or 7 to 8 lithium-ion cells. Factors such as battery chemistry, application needs, and desired

How many power strings are needed to assemble lithium

Here''''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and

Battery Series and Parallel Connection Calculator

Jun 16, 2024 · For example, if you connect two 12-volt batteries in series, you''d get a 24-volt system. This doubles the voltage while keeping the overall capacity the same. Parallel

How many strings of lithium battery packs are there

How many series elements are in a lithium ion battery pack? For example, a lithium-ion battery pack marked as 10.8 V nominal, 7.2 Ah can be assumed to contain three series elements (3 ×

How many strings of 24 volt lithium battery packs are needed

Therefore, the lithium battery must also be about 58v, so it must be 14 strings to 58.8v, 14 times 4.2, and the iron-lithium battery is fully charged to about 3.4v, four strings must be 12v, 48v

How many strings of 24v lithium battery packs should I use

Example: If two batteries of 200Ah (amp-hours) and 24V (volts) each are connected in series, the resulting output voltage is 48V with a capacity of 200 Ah. 4 · Areas We Use 24V

How many strings of 24V lithium iron phosphate batteries

How many cells are in a set of lithium iron phosphate batteries? The whole set of batteries is 14 strings multiplied by 10 cells = 140 cells. Summary: Series and parallel have their own

How many strings of 24v lithium battery packs should I use

4 · Areas We Use 24V Lithium Batteries in Real-Life. 24-volt Lithium battery packs also have various applications. However, the range of users is relatively less

How Many Cells in a 24 Volt Battery? Lead-Acid vs. Lithium Battery

Mar 14, 2025 · How Many Cells Are Needed for a 24 Volt Battery Configuration? A 24-volt battery configuration typically requires a specific number of cells based on the type of battery used.

Onlin free battery calculator for any kind of battery : lithium

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Battery Pack Calculator | Good Calculators

Battery Pack Calculator Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and

6 FAQs about [How many strings of 24 volt lithium battery packs are needed]

Can a lithium ion battery pack have multiple strings?

Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However, sometimes it may be necessary to use multiple strings of cells. Here are a few reasons that parallel strings may be necessary:

How many volts are in a battery pack?

If each cell is 10 amp hours and 3.3 volts, the battery pack above would be 10 amp hours and 26.4 volts (3.3 volts x 8 cells). For this setup, a BMS capable of monitoring 8 cells in series is necessary. Lithium cells can almost always be paralleled directly together to essentially create a larger cell.

How many volts does a lithium battery have?

Different battery types have different nominal voltages. For example, it's 1.2V for nickel, 1.5V for alkaline, 1.6V for silver-oxide, and 2.0V for lead acid. Lithium cells can vary from 3.0V to 3.9V. Series connections might give you a 14.4V from 4 Li-ion cells. Or 12V from 6 lead acid cells, and even 6V from 4 alkaline cells.

How many lithium batteries should a solar array have?

It's wise to only series-connect up to four lithium batteries to make 48 volts, to prevent damage. In parallel, batteries share the same voltage. This practice ups amp hours without changing the voltage, which goes up to eight batteries for solar arrays. Series setups make batteries last longer than in parallel.

Should a battery pack be paralleled?

Paralleling strings together greatly increases the complexity of managing the battery pack and should be avoided unless there is a specific reason to use this configuration. In this setup, each string must essentially be treated as its own battery pack for a variety of reasons. In a below example, 2 strings of 8 cells each are placed in parallel.

How many volts can a 12V 30ah battery make?

Say we join two 12V 30Ah batteries in series. Now, we get 24V. In parallel, you'd have 60 amp hours. It's wise to only series-connect up to four lithium batteries to make 48 volts, to prevent damage. In parallel, batteries share the same voltage.

Update Information

- How many Prague lithium battery packs are connected in series at 72 volts

- Brand new 24 volt lithium battery inverter dedicated

- How big a battery is needed for 7KW photovoltaic energy storage

- Lithium battery packs for sale in Latvia

- How much does the Copenhagen lithium battery pack cost

- How much is the Gaborone lithium battery pack

- How much is the Castries lithium battery pack

- 8 groups of lithium iron phosphate battery packs connected in series

- How about lithium iron phosphate battery for photovoltaic energy storage cabinet

- How much is the lithium battery replacement cabinet in Northern Cyprus

- Advantages of Greek lithium battery packs

- Are lithium battery packs cheap in Swaziland

- 13 lithium battery packs have different voltages

Solar Storage Container Market Growth

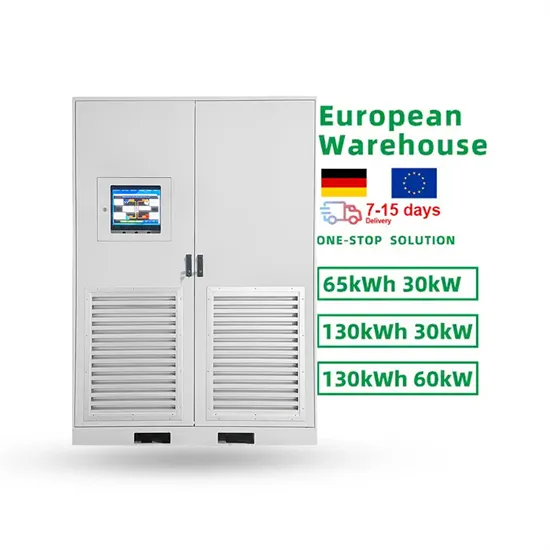

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.