difference between PV input and MPPT range

Aug 31, 2021 · MPPT Range is the voltage range (in this case 125V - 425V) over which your MPPT will operate effectively and be able to extract power from your array. PV Input Voltage

Accuracy specifications: Reading it right with range

Apr 13, 2020 · How the measurement range affects accuracy specifications Power meter manufacturers are largely in agreement with accuracy being defined in the form "x% of the

OV_DC: DC Over Voltage

4 days ago · OV_DC: DC Over Voltage The "DC Over Voltage" error means the DC input voltage from the solar strings exceeds the inverter''s limits. Why it''s problematic High DC voltage can

Photonik | String Voltage Calculator

Oct 13, 2023 · Throughout the day, many variables will influence the string voltage, including; weather, shading and temperature. As the string voltages changes, the MPPT will

Mppt voltage range vs max DC input voltage

Feb 14, 2024 · what''s the difference between max MPPT voltage range and max DC input voltage? My inverter max dc input is 600V and the max range goes up to 550V. I''m wanting to

High Current Measurement Application Guide

Apr 13, 2020 · A manufacturer of inverter based motor drives is engineering an instrumentation system for benchmarking power measurements on 3 phases of PWM based AC voltage,

AC and DC Voltage Measurement

Aug 18, 2025 · There are two different types of voltage probes: The pure resistor voltage probe (for AC and DC measurement) and the resistor-capacitive voltage probe (for AC measurement

Exceeding Inverter Limits

Feb 2, 2020 · The general rule of thumb is that your inverter Max Input voltage must be greater than Voc x 1.2, otherwise the inverter will shut down (if you are very lucky) or fry (more likely).

Inverter report over voltage and motor abnormal voltage measurement

To measure the DC bus voltage, you can use a 47-type multimeter set to 1000V DC mode to measure the voltage across the DC bus. Most inverters are designed with an over-voltage

Top 13 Causes of VFD Overvoltage Fault

Discover the top 13 causes of VFD overvoltage fault, from input voltage spikes to braking circuit failures. Learn how to prevent DC bus overvoltage in variable frequency drives with accurate

6. Troubleshooting and Support

Jun 17, 2025 · High DC ripple is usually caused by loose DC cable connections and/or too thin DC wiring. After the inverter has switched off due to high DC ripple voltage, it waits 30 seconds

IQ Series VRise tech brief V9.2 final

Feb 3, 2024 · The IEEE 1547 standard requires that grid-tied or utility-interactive inverters cease power production if voltage measured at the inverter terminal exceeds +10% or -12% of nominal.

Fault codes and troubleshooting steps 011-020

This manual is intended for professional technicians who are responsible for installation, operation, maintenance and troubleshooting of inverters, and users who need to check

6 FAQs about [Inverter DC voltage measurement exceeds range]

How to test a DC inverter?

1. Use the voltage range of the multimeter to measure the DC input voltage of the inverter. When the voltage is normal, the total voltage is the sum of the voltages of each component. 2. If there is no voltage, check the DC switch, terminal blocks, cable connectors, components, etc. in turn to see if they are normal.

What is a normal voltage for an inverter?

The inverter shouldoperate normallywhen the input DCvoltage is in therange of 90–120percent of the nomi-nal input voltage.During the normaloperation of theinverter, its AC out-put voltage mustremain in the rangeof 220 volts ± 10%. (b) Inverter output oper-ating frequencyshould be in therange of 50 Hz ± 5%.

What is the maximum voltage rise for an inverter?

The maximum voltage rise for a system must be 4.6V (2%). For example, the local grid may be functioning at 252V, and your inverter is exporting 4V back into the grid pushing it over the grid standard. In 2016, significant changes to AS 4777.2 occurred and a 255V output was set on inverters.

How to regulate AC voltage in a grid connected inverter?

Try to shorten the line length of the inverter AC output end, or use thicker copper core cables to reduce the voltage difference between the inverter and the grid. 3. Now most grid-connected inverters have AC voltage regulation function.

Why does a DC inverter report 'PV impedance is too low'?

When it detects that the DC positive and negative poles have an impedance to the ground lower than 50kQ, the inverter will report "PV insulation impedance is too low fault" to prevent the human body from contacting the live part of the panel and the ground at the same time, causing the risk of electric shock.

Why is my inverter LCD not working?

There is no DC input or the auxiliary power supply is faulty. The inverter LCD is powered by DC, and the component voltage cannot reach the inverter startup voltage. 2. The PV input terminal is connected in reverse.

Update Information

- Inverter is suitable for DC voltage regulation

- High Voltage DC Step-Down Inverter

- Ecuador Inverter DC Voltage Wholesale

- The voltage is low after inverter rectification

- Fully automatic emergency AC DC inverter

- DC to AC inverter charging adapter

- Slovakia DC inverter zlb-250

- How many volts is the inverter voltage in Lusaka

- Inverter rear bridge output voltage is too low

- How big is the DC panel inverter usually

- High voltage inverter 28000

- Does the inverter have a DC output

- Berlin imported DC inverter

Solar Storage Container Market Growth

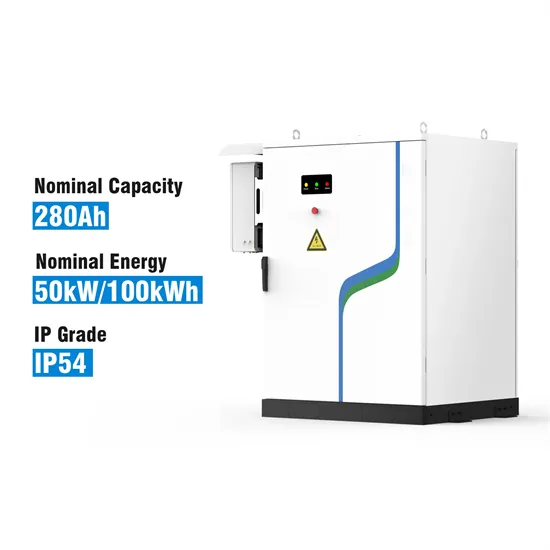

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.