JA Solar PV Bifacial Double-glass Modules Installation

Jun 4, 2025 · Frameless double glass modules and composite frame modules need not be grounded. JA Solar modules use an anodic oxidized aluminium frame or steel frame to resist

INSTRUCTIONS FOR PREPARATION OF PAPERS

Jul 12, 2025 · The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass

Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · In double-glass or glass-glass PV modules the polymer back sheet layer is replaced by a glass layer identical to the top glass, creating a symmetrical "sandwich" structure.

JA Solar PV Bifacial Double-glass Modules

Feb 1, 2021 · JA Solar modules can be mounted in landscape or portrait orientation. For the bifacial modules, in order to maintain the energy yield of module rear side, the distance

Double-glass PV modules with silicone encapsulation

May 21, 2024 · In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is

JA Solar PV Bifacial Double-glass Modules Installation

Jul 18, 2025 · The connection between photovoltaic module and photovoltaic module bracket should be in the form of fixed aluminum alloy press block standard parts, rail groove insertion

Reducing the temperature of monofacial double-glass photovoltaic module

Apr 1, 2025 · At the same time, a standard monofacial double-glass module was prepared as reference module to obtain the cooling effect of the EAG and CAE PV mini modules in outdoor

JA Solar PV Bifacial Double-glass Modules Installation

Nov 20, 2024 · The connection between photovoltaic module and photovoltaic module bracket should be in the form of fixed aluminum alloy press block standard parts, rail groove insertion

直角 JAM72D10 400-420 MB

Jan 22, 2020 · Introduction Assembled with MBB bifacial PERCIUM cells and half-cell configuration, these double glass modules have the capability of converting the incident light

DAS-DH144NA-EN-565-585(2278-1134-30)

Sep 11, 2023 · Mechanical Parameters Cell Type Module Size Glass Thickness Module Weight Output Cable Connector Junction Box Frame N Type 2278×1134×30mm 2.0mm 31.3Kg

N型-英文全框-HD108N-11BB-410-425-182-A

Jun 6, 2024 · Linear Performance Warranty Standard Module Linear Performance Warranty Jolywood N-type Bifacial Double Glass Module Linear Performance Warranty 99.0% 97.0%

Thermal and electrical performance analysis of monofacial double-glass

Nov 1, 2023 · The monofacial double-glass photovoltaic modules are still seriously affected by the temperature effect. The coatings with spectral regulation characteristics are expected to

T/CPIA 0028.2-2021 光伏组件用玻璃 第2部分:双玻组件

Jul 16, 2025 · T/CPIA 0028.2-2021 光伏组件用玻璃 第2部分:双玻组件背板增反射镀层玻璃 Glass for Photovoltaic Modules Part 2: Double-glass Module Backsheet Enhanced Reflection Coated

Bifacial Module with Double Glass xxxG12 66HSW

Dec 19, 2023 · Type: DMxxxG12-B66HSW Power Range: 655 - 670 W Max. Efficiency : 21.6 % Bifacial Module Application Up to 25 % higher electricity yields due to active cell technology in

6 FAQs about [Double glass module standard]

What is a double glass module?

Double glass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet. With * Corresponding author. Tel.: +86 13776101913; fax: +86 51268961413.

How reliable is Canadian Solar's Dymond double glass module?

Canadian Solar’s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully indicate high lifetime and high reliability of this double glass module. This paper presents a detailed reliability study of Canadian Solar’s Dymond double glass module.

What is a double-glass solar module?

ABSTRACT: Double-glass modules provide a heavy-duty solution for harsh environments with high temperature, high humidity or high UV conditions that usually impact the reliability of traditional solar modules with backsheet material.

What is double glass PV module?

Double glass PV module is known as the ultimate solution for the module encapsulation technique. Although double glass modules have many advantages, they are not yet widely used in photovoltaic power plants, for which one important reason is the large power loss due to the transmission of light in the cell gap region.

What is glass–glass module technology?

In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability. The concept enables safe module operation at a system voltage of 1,500V, as well as innovative, low-cost module mounting through pad bonding.

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

Update Information

- Photovoltaic module double glass insulation

- Huawei double glass floodlight module

- Tuvalu double glass photovoltaic module manufacturer

- Amorphous silicon cell double glass module

- 9BB double glass module

- Double glass module cross-linking degree

- Double glass module 36 pieces

- North Macedonia double glass module manufacturer

- Double glass module structure

- Southern Europe Double Glass Photovoltaic Module Company

- Tunisia double glass photovoltaic module price

- What is a single crystal double glass module

- Kinshasa double glass photovoltaic module price

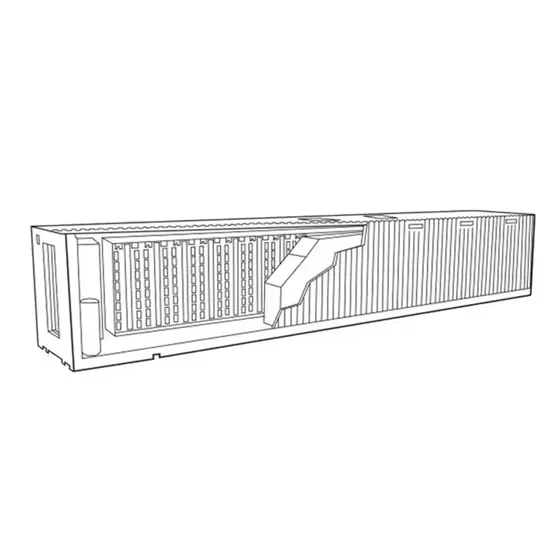

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.