Effect of crosslinking rate on the glass transition temperature

Aug 8, 2020 · The polyimide cross-linked silica aerogels (PI -SiO2) was constructed at the atomistic level. The specific volume-temperature curves of the materials at different

Effect of UV ageing on debonding of double glass laminates

Request PDF | On Aug 1, 2024, Martin Tiefenthaler and others published Effect of UV ageing on debonding of double glass laminates based on different crosslinking and thermoplastic PV

Non-destructive quality assessment of PV module

Jul 5, 2024 · Features Non-destructive measurement of the degree of cross-linking of encapsulant Stand-alone for full module mapping In-line for fixed locations for high volume testing

Non-destructive determination of the cross-linking degree

The gel content of photovoltaic module encapsulation Ethylene-vinyl acetate (EVA) is usually measured by the Soxhlet extraction method. Due to the destructive sample preparation, long

Carboxymethyl chitosan/polyacrylamide double network

Nov 1, 2024 · Some carboxymethyl chitosan constructed hydrogels with high cross-linking by physical or chemical cross-linking, conferring a dense cross-linked network, so that it allows

Investigation of Ethylene/Vinyl Acetate Copolymer (EVA) by

Apr 1, 2011 · Two types of commercially applied Ethylene/Vinyl Acetate Copolymers (EVA) for encapsulation of photovoltaic modules were investigated by the thermal analysis methods of

Comparison between the DSC degree of crosslinking (left)

This paper investigates the influence of a double-side heating system in the lamination process for a glass-backsheet PV module. This effect was evaluated by comparing the gel content of

EVA cross-linking degree determination.

Download scientific diagram | EVA cross-linking degree determination. from publication: Zinc-selective light diffuser for enhanced efficiency and reduced degradation in photovoltaic

Update of quality control tests for new PV encapsulation

Feb 15, 2024 · The cross-linking reaction initiated by the thermal process in the laminator is essential for the material properties of the encapsulation films and thus for the long-term

Sampling method for cross-linking degree of packaging

A technology of double-glass components and internal packaging, which is applied in the direction of sampling, analyzing materials, and measuring devices. It can solve the problems of cross

Non-destructive determination of the cross-linking

Oct 9, 2023 · Solvent extraction was used as reference technique. For the Raman spectroscopic investigation of the degree of cross-linking, residual peroxide peaks from the cross-linking

UT2061 Pipe Crosslinking Determination Tester_Other Pipe

UT2061 Cross-linking determination test system is used as a test of EVA cross-linking, polyethylene (PE) cross-linking, polyethylene insulated wire and cable (XLPE) cross-linking,

Chemical reactions of polymer crosslinking and post-crosslinking

Feb 1, 2011 · This review focuses on various strategies that enable the crosslinking and post-crosslinking of polymers, excluding crosslinking obtained by radiation

Photovoltaic solar panel double glass lamination tooling

What is the fastest two-stage lamination process for glass-glass modules? The fastest two-stage lamination process for glass-glass modules and glass backsheet modules is based on a

Determination of the cross-linking degree of commercial

Apr 30, 2014 · The degree of cross-linking of the EVA achieved during the lamination process is a decisive parameter for the durability and long-term stability of the module. In this context the

Influence of the Lamination Pressure on the Adhesion,

Feb 2, 2024 · The degree of crosslinking for encapsulants was also compared using DSC and Soxhlet measurement methods. The results show that the lamination pressure above

Temperature Distribution during the Lamination Process

Sep 20, 2023 · In this study, we conducted thermocouple measurements across module layers to observe temperature profiles and gauge the degree of crosslinking in glass-backsheet (GB)

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Investigation of Ethylene/Vinyl Acetate Copolymer (EVA) by

Apr 1, 2011 · Glass transition, crystal melting and cross-linking were analyzed. The aims of the investigations were to gain more information for incoming goods control and to get information

Determination of the cross-linking degree of commercial

Aug 28, 2017 · The degree of cross-linking of the EVA achieved during the lamination process is a decisive parameter for the durability and long-term stability of the module. In this context the

Enhancing photovoltaic modules encapsulation: Optimizing

Apr 1, 2024 · These materials are polyethylene-based and require the use of curing agents for cross-linking, similar to EVA. The POE encapsulants offer notable advantages, including

Influence of the Lamination Pressure on the Adhesion,

Feb 2, 2024 · The degree of cross-linking is calculated by comparing the reaction enthalpy from an exothermic peak on the heat flow plot in the software of the cured sample to the uncured

Explore the Accurate Measurement of EVA Cross-linking Degree

In the manufacturing process of photovoltaic cells, the cross-linking degree of the EVA layer is an important factor in determining its performance. As a packaging material, the EVA layer not

Standardized cross-linking determination methods

Aug 2, 2025 · Throughout this optimization process, several tests are recommended to verify the degree of cross-linking and the amount of remaining peroxides within the modules.

Crosslinking degree of EVA in photovoltaic module

Sep 30, 2024 · The cross-linking degree detection data will directly reflect the reliability of solar module packaging, thereby determining the quality of solar modules.

Thermal conductivities and mechanical properties of epoxy

Dec 1, 2021 · Here, molecular dynamics simulations are used to calculate, compare, and elucidate connections between both thermal conductivities and mechanical properties of an

6 FAQs about [Double glass module cross-linking degree]

Does cross-linking change glass transition temperature?

Similarity between 1st and 2nd runs show that the glass transition temperature was not noticeable changed by cross-linking. It is interesting that the DSC peak in the 2nd run at 63 °C, indicating crystal melting, correlates well with the sharp decrease of the storage modulus of the cured sample in the area between 40 and 70 °C.

How do we measure crosslinking levels in PV modules?

2.1 Soxhlet Extraction To assess the lamination process, the degree of crosslinking values measured on the front and rear side of the PV modules are compared. For this purpose, we adopted Soxhlet extraction, a straightforward time-intensive technique widely used for measuring crosslinking levels in PV modules [6,7].

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

What is glass–glass module technology?

In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability. The concept enables safe module operation at a system voltage of 1,500V, as well as innovative, low-cost module mounting through pad bonding.

How is encapsulation crosslinking determined in a lamination model?

In order to achieve the degree of crosslinking of the encapsulation material in the lamination model, the chemical reactions of the EVA is determined by Differential Scanning Calorimetry (DSC), allowing to obtain the crosslinking reaction, which assists in determining the activation energy.

Update Information

- Double glass module 36 pieces

- Double glass module structure

- Photovoltaic module double glass insulation

- Double glass module recommendation

- Kinshasa double glass photovoltaic module price

- Tuvalu double glass photovoltaic module manufacturer

- Double glass module bvd

- What is a single crystal double glass module

- Solar double glass aluminum alloy components

- Bulgarian thin film photovoltaic module glass

- Sierra Leone single glass photovoltaic module price

- Niamey standard photovoltaic module glass

- Installation of double glass light transmission components

Solar Storage Container Market Growth

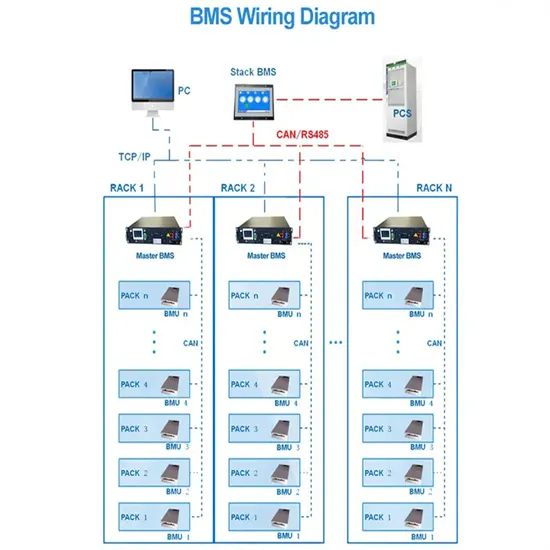

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.