What are the differences between single-glass

Oct 22, 2020 · Furthermore, comparing to plastic backsheets (the back material of single-glass solar module) which are reactive, glass is non-reactive. This

JA Solar PV Bifacial Double-glass Modules

Feb 1, 2021 · JA Solar modules can be mounted in landscape or portrait orientation. For the bifacial modules, in order to maintain the energy yield of module rear side, the distance

Double Glass Technology: Harnessing Authentic Advantages

Nov 29, 2023 · In summary, double glass solar modules, with their authentic structure and exceptional performance, spearhead the development trajectory of the solar energy industry.

What is photovoltaic double glass panel technology

What is photovoltaic double glass panel technology Glass-glass module structures (Glass Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of

INSTRUCTIONS FOR PREPARATION OF PAPERS

Jul 12, 2025 · The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum

What is the Double Glass(Dual Glass) Photovoltaic Solar Panel?

Dec 31, 2024 · What is the Double Glass Photovoltaic Solar Panel? Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of

JA SOLAR PV MODULES INSTALLATION MANUAL

Jan 29, 2019 · The modules clamps must not contact the glass directly or deform and damage the glass in any cases, clamp need embedded with the rubber washer, which plays a buffer

JA Solar PV Bifacial Double-glass Modules Installation

Nov 20, 2024 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules.

Double-glass PV modules with silicone encapsulation

May 21, 2024 · In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is

For N-type Bifacial Technology, Dual Glass Structure is

Feb 28, 2023 · A glass/backsheet structure works well with conventional PERC modules due to its lightweight, whereas a glass/glass structure has the potential to generate additional energy for

Bifacial single glass encapsulation of solar module – An

Jul 1, 2025 · Outdoor performance of PV modules encapsulated with two different approaches showed that annual power generation of single glass solar modules was higher than that of

Conventional module and Double glass module structure,

Download scientific diagram | Conventional module and Double glass module structure, respectively [20]. from publication: A review and analysis of technologies applied in PV

High performance double-glass bifacial PV modules

Oct 5, 2016 · Double-glass structure shows a loss of ~ 1.30% compare to the glass/backsheet structure under STC measurements. J. P. Singh, et al. "Comparison of Glass/glass and

6 FAQs about [Double glass module structure]

What is a double glass module?

The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum frame of conventional modules and frame-grounding requirements. The application of double-glass modules covers multiple markets including utility, residential and commercial.

What is a double glass (Dual Glass) solar panel?

A double glass (Dual Glass) solar panel is a glass-glass module structure where a glass layer is used on the back of the modules instead of the traditional polymer backsheet. Double glass solar panels were originally heavy and expensive, but the lighter polymer backing panels gained most of the market share.

What is a glass-glass solar panel?

Glass-glass module structures (Glass Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of the traditional polymer backsheet. Originally double-glass solar panels were heavy and expensive, allowing the lighter polymer backing panels to gain most of the market share. Thanks to producers such as:

Are double-glass solar modules reactive or non-reactive?

Furthermore, comparing to plastic backsheets (the back material of single-glass solar module) which are reactive, glass is non-reactive. This means that the whole structure of Raytech double-glass solar modules (two layers of glass and one layer of solar cells in the middle) are highly resistant to chemical reactions such as corrosion as a whole.

What is a double-glass solar module?

ABSTRACT: Double-glass modules provide a heavy-duty solution for harsh environments with high temperature, high humidity or high UV conditions that usually impact the reliability of traditional solar modules with backsheet material.

What changes have been made in glass-glass modules?

In the case of Glass-Glass modules, an important change has been made by replacing EVA with polyolefins as an encapsulating substance. This is due to the free radicals generated during the EVA cross-link lamination process. Traditional backsheets are somewhat permeable to free radicals, but the double glass module is not.

Update Information

- Southern Europe Double Glass Photovoltaic Module Company

- Double glass module 36 pieces

- North Macedonia double glass module manufacturer

- Double glass module recommendation

- Is the double glass module good

- Tunisia double glass photovoltaic module price

- Huawei double glass floodlight module

- What is a single crystal double glass module

- Application scenarios of single and double glass components

- Buenos Aires Glass PV Module Sales

- Module TypeDouble GlassSingle Glass

- Libreville single-glass photovoltaic module glass

- Funafoti double glass photovoltaic curtain wall customization

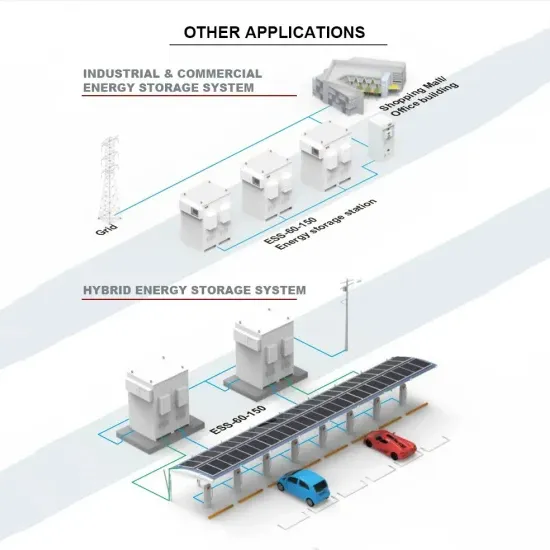

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

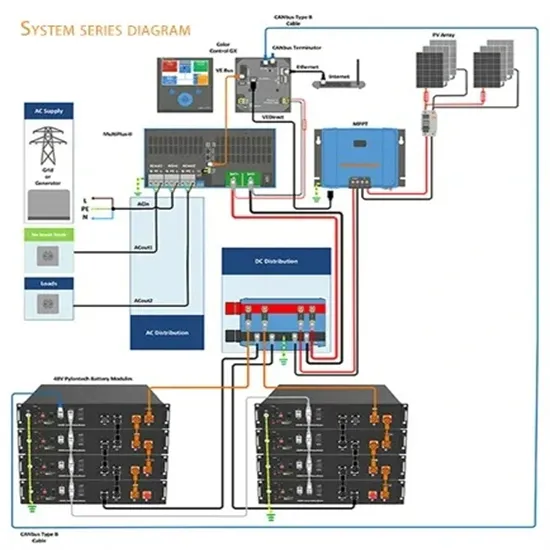

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.