Manufacturer in China Bifacial Solar Panels Double Glass PV Modules

Jul 31, 2025 · Manufacturer in China Bifacial Solar Panels Double Glass PV Modules 400W 450W 500W 550W 600W Half Cell Photovoltaic Solar Panels US$0.09 10,000-99,999 Watt/Watts

Top Solar Panel Manufacturers Suppliers in Tuvalu

Apr 16, 2025 · Another emerging PV technology using MJ cells is concentrator photovoltaics (CPV). CPV also generates electricity from sunlight, but unlike conventional photovoltaic

Solar Panels Suppliers Manufacturers Tuvalu, Solar Panels

We are a professional company engaged in the manufacturing and distribution of solar panel starting 3wp-340wp from our state of the art manufacturing facility based The facility is

Trina Solar: Double-Glass

Jun 25, 2019 · After years of growth, double-glass modules have now become a must-have option for PV module manufacturers to sell their products. According to the statistics, double-glass

PVB中间膜_智能电致变色膜_光伏玻璃_太阳能光伏组件-Quantum

Quantum offers high value-added PVB film including standard clear PVB, soundproof or acoustic PVB film, thermal insulating PVB film, acoustic and solar insulating PVB film, shaded band

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers.

Double Glass Module Photovoltaic Glass Market

Key Drivers Accelerating Double Glass Module Adoption in the Global Photovoltaic Market The shift toward double glass modules in the photovoltaic industry is driven by their **superior

Global Double Glass Module Photovoltaic Glass Market 2024

Double glass module photovoltaic glass is a glass module used in solar photovoltaic systems. It is different from traditional single-glass module photovoltaic glass. Double-glass module

OEM double-glass pv module Manufacturer,Factory Supply double-glass pv

Nov 15, 2023 · Double-Glass Construction: The dual-sided glass design not only enhances durability but also allows for bifacial generation, making it a versatile solution for various

Tuvalu Photovoltaic Solar System Manufacturer

Tuvalu solar photovoltaic panels In 2007, Tuvalu was getting 2% of its energy from solar,through 400 small systems managed by the Tuvalu Solar Electric Co-operative Society. These were

Double Glass PV Modules Market''s Evolution: Key Growth

Mar 28, 2025 · The double glass PV module market, currently valued at approximately $22,060 million in 2025, is experiencing robust growth, projected to expand at a compound annual

Aluminum foils can reduce temperature in double-glass PV modules

Jan 30, 2025 · The results were presented in "Reducing the temperature of monofacial double-glass photovoltaic module by enhancing in-plane thermal conductivity," published in Next

Double Glass Module Photovoltaic Glass Unlocking Growth

Mar 29, 2025 · The double-glass module photovoltaic (PV) glass market is experiencing robust growth, driven by increasing demand for higher efficiency and durability in solar energy

What is photovoltaic double glass panel technology

What is photovoltaic (PV) technology and how does it work? PV materials and devices convert sunlight into electrical energy. A single PV device is known as a cell. An individual PV cell is

Double Glass Module, Wholesale Double Glass Module

620W 144 Pieces of Double Glass Half-piece Monocrystalline Solar Photovoltaic Module PRODUCT DETAILSMulti-busbar TOPCon (MBB)10 busbar cells are used. Fully upgraded to

Specialist in Solar Panel Manufacturing Equipment | Horad

Jan 16, 2025 · Turnkey Solutions for PV Modules Manufacturing We offer complete solar panel production lines for global customers to manufacture photovoltaic modules based on their

China Double Glass PV Module Manufacturers Factory

SHINEFAR is one of the most professional bifacial single glass solar panels manufacturers and suppliers in China, specialized in providing high quality custom service. Please feel free to

BIFACIAL SERIES – GLASS-TO-GLASS PHOTOVOLTAIC

Dec 4, 2012 · ECONOMICS Bifacial G2G technology is a turning point in photovoltaic (PV) system technology. It replaces costly single-axis and double-axis mechanical tracking systems with

6 FAQs about [Tuvalu double glass photovoltaic module manufacturer]

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

What is the best double-glass module?

When it comes to double-glass, Trina Solar’s double-glass module is the most sought after product in the market. It was one of the first companies to promote and commercialize double-glass modules, and it has won industry-wide recognition for its high quality.

Are early PV modules encapsulated with silicone?

Photovoltaics International Early PV modules were often encapsulated with silicone, and have demonstrated outstanding stability in the field, with degradation rates over 20 to 30 years that are much lower than the typical degradation rates for EVA-encapsulated modules [3–5].

What encapsulant materials can be used for PV modules?

Various encapsulant materials can be considered. Polyvinyl butyral (PVB) has been used for a long time for glass–glass PV modules, particularly for thin-film modules.

How thick is a PV module?

The total thickness of module is between 4.5-5mm. Dual glass solution is becoming nowadays the trend for future PV industry, with advantage of better mechanical strength and better weathering performance due to the fact the back sheet is made of a similar inorganic glass as that of front sheet.

Update Information

- Bloemfontein double glass photovoltaic module manufacturer

- Kinshasa double glass photovoltaic module price

- Southern Europe Double Glass Photovoltaic Module Company

- Tunisia double glass photovoltaic module price

- Photovoltaic module double glass insulation

- What is the current price of single crystal double glass photovoltaic panels

- Is double glass in photovoltaic modules conductive

- Argentina photovoltaic cell module manufacturer

- Sri Lanka photovoltaic glass manufacturer

- Maldives photovoltaic module inverter manufacturer

- Amorphous silicon cell double glass module

- Laos light-transmitting photovoltaic glass manufacturer

- Grenada double glass photovoltaic modules

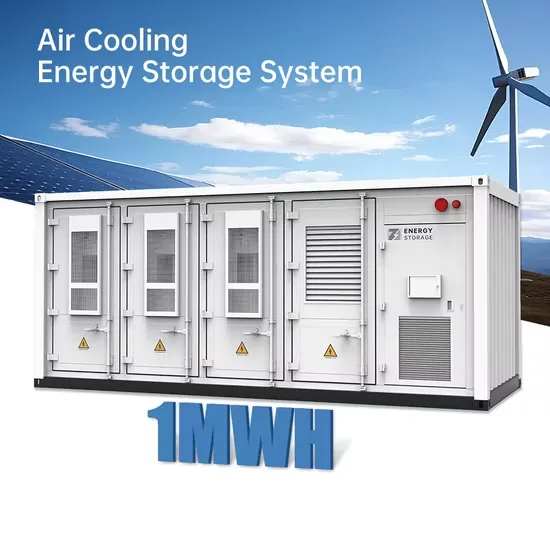

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.