Review of mechanical design and strategic placement

Jul 1, 2016 · Strategic battery pack placement technique is also discussed using an example of Nissan LEAF battery packaging design. Finally, the disclosed design solutions described in

Coupled Mechanical-Electrochemical-Thermal Modeling

Jun 10, 2015 · II. Electric vehicles (EVs) must be as safe as other road vehicles, particularly during a crash; need to understand crushed battery''s thermal response In 2014, U.S. DOE initiated

Metallurgical and mechanical methods for recycling of lithium

Sep 1, 2018 · Higher degree of automation and intelligence in the mechanical dismantling process were the main challenges for recycling of lithium ion battery pack from EVs. Most of the

Effect of external pressure and internal stress on battery

Nov 1, 2022 · There are abundant electrochemical-mechanical coupled behaviors in lithium-ion battery (LIB) cells on the mesoscale or macroscale level, such as elect

Mechanical Design of Battery Pack

Aug 18, 2023 · In the mechanical design of batteries, the widespread adoption of electric vehicles faces two major challenges: safety and reliability. Current Li-ion battery packs are susceptible

Review of Lithium-Ion Battery Internal Changes

Jul 22, 2024 · The growth of electric vehicles (EVs) has prompted the need to enhance the technology of lithium-ion batteries (LIBs) in order to improve their

Battery Pack Design of Cylindrical Lithium-Ion Cells and

Sep 12, 2022 · In terms of mechanical structure, the basic structure of a battery pack is determined by the desired performance as well as cell characteristics. In this research, the

Metallurgical and mechanical methods for recycling of lithium-ion

Sep 1, 2018 · In recent years, many studies have focused on single recycling methods based on mechanical and metallurgy processes (Meng et al., 2017; Golmohammadzadeh et al., 2017).

EV Battery Pack Design: Key Mechanical & Safety Factors

This article explores the key considerations for designing a battery pack for electric vehicles (EVs), focusing on four crucial aspects: mechanical, safety, maintenance, and cost. 1.

EV Battery Pack Design: Key Mechanical & Safety Factors

The battery pack design must consider potential abuse situations like short circuits, overcharge, and penetration, ensuring safety and preventing thermal runaway in lithium-ion batteries.

Electrochemical-Thermal-Mechanical Coupling of

May 16, 2025 · a lithium ion battery stack, each cell consists of Graphite(LiC6) anode/Separator/high performance layered LMO(LiMn2O4) or NCM(LiNi1/3Co1/3Mn1/3O2)

Mechanical issues of lithium-ion batteries in road traffic

Aug 1, 2024 · Mechanical abuse stands out as a significant contributor to battery fire and explosion incidents, prompting the establishment of safety standards and heightened concerns

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Mechanical integrity of 18650 lithium-ion battery module:

Sep 1, 2018 · The crash safety of lithium-ion batteries (LIBs) has recently become a hot research topic because of the wide application of LIBs in vehicle. This paper investigates how packing

The Handbook of Lithium-Ion

Aug 16, 2025 · The Handbook of Lithium-Ion Battery Pack Design This page intentionally left blank The Handbook of Lithium-Ion Battery Pack Design Chemistry, Components, Types and

6 FAQs about [Mechanical lithium battery pack]

Can a prismatic Lithium-ion battery pack be mechanically designed?

Development of a mechanical design of a prismatic lithium-ion battery pack for an electric vehicle. Journal of Power Sources, 274, 455-461. Zhang, Z., Zhang, F., & Bai, J. (2020). Multi-objective mechanical design optimization for prismatic lithium-ion battery pack structure. Applied Energy, 276, 115416.

What is an automotive lithium-ion battery pack?

An automotive lithium-ion battery pack is a device comprising electrochemical cells interconnected in series or parallel that provide energy to the electric vehicle. The battery pack embraces different systems of interrelated subsystems necessary to meet technical and life requirements according to the applications (Warner, 2015).

How can mechanical design and battery packaging protect EV batteries?

Robust mechanical design and battery packaging can provide greater degree of protection against all of these. This chapter discusses design elements like thermal barrier and gas exhaust mechanism that can be integrated into battery packaging to mitigate the high safety risks associated with failure of an electric vehicle (EV) battery pack.

What is the mechanical-electrochemical coupling behavior of lithium-ion batteries?

The mechanical–electrochemical coupling behavior is a starting point for investigation on battery structures and the subsequent battery design. This perspective systematically reviews the efforts on the mechanics-based design for lithium-ion batteries (LIBs).

How mechanical design elements affect safety and reliability of EV battery packaging?

In this chapter, mechanical design elements affecting safety and reliability of EV battery packaging are discussed. Forces like mechanical vibration, impact energy and ambient temperature variations interact with the battery pack through different interfaces. These interactions need to be controlled for safe and reliable operation of battery pack.

What materials are used in lithium batteries?

Despite different materials are utilize in the lithium cells, the batteries are named in regard to the cathode composition such as lithium Cobalt oxide (LiCoO2), Lithium Nickel Cobalt Aluminium Oxide (NCA), lithium-ion phosphate (LFP) and lithium manganese Oxide (LiMnO4).

Update Information

- Which lithium battery pack is the best in Oslo

- Manila lithium battery pack company

- Lithium battery pack active balancing BMS passive balancing

- Lithium iron phosphate battery pack press assembly

- How much is the lithium iron phosphate battery pack

- Torch lithium battery pack customization

- Berlin lithium battery pack processing

- What is MOS for lithium battery pack

- Which lithium battery pack has the best price

- Which battery cell is better for Roman lithium battery pack

- Lithium iron phosphate battery pack 25 6v71 5ah

- Pack future lithium battery

- San Diego Lithium Titanate Battery Pack BMS

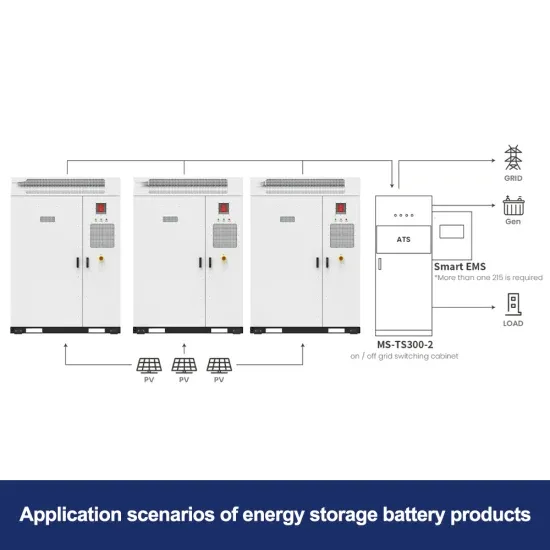

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.