Best Lithium Iron Phosphate 12V Battery Pack | LiFePO4

Mar 19, 2025 · A Lithium Iron Phosphate 12V battery pack is a top-tier energy storage solution that delivers long-lasting performance, safety, and efficiency. Whether for renewable energy,

HOW MUCH DOES A LITHIUM IRON PHOSPHATE BATTERY

Are lithium iron phosphate batteries good for energy storage? Lithium iron phosphate batteries (LFPBs) have gained widespread acceptance for energy storage due to their exceptional

What Are The Implications Of $66/kWh Battery Packs In China?

Dec 26, 2024 · Assuming they get to $80 per kWh for EV LFP battery packs, then the US tariff of 25% makes them about $100 per kWh. That''s below Tesla''s US cost of $100–$120 per kWh

Lithium Iron Phosphate Batteries: Understanding the

Aug 3, 2023 · 3. Ultra-Safe Battery Chemistry The LFP technology built into our MPower battery systems offers a high level of chemical and thermal stability, making LFP batteries much safer

CATL, BYD To Slash Battery Prices By 50% In 2024. BOOM!

Feb 26, 2024 · CATL and BYD are both on a path to decrease battery prices this year by as much as 50%, meaning battery packs at the end of 2024 could cost half what they did at the end of

Explore LFP Battery Raw Material: LFP Cathode

Jan 30, 2024 · Lithium iron phosphate is an important cathode material for lithium-ion batteries. Due to its high theoretical specific capacity, low manufacturing

[Battery 101] NMC vs LFP (chemistry, differences,

Jun 20, 2024 · Especially with LFP (Lithium Iron Phosphate) packs, just charge the darn thing to 100% and maximize the full range potential. If it makes you

The Cost of Lithium Iron Phosphate Energy Storage: What

Oct 26, 2022 · Battery packs (50-60% of total): Prices have dropped to $95-$130/kWh thanks to scaled production [3] [10]. Battery Management Systems: The "brain" costs $15-$25/kWh to

Lithium-Ion Battery Pack Prices See Largest Drop Since

Dec 10, 2024 · Lithium-ion battery pack prices dropped 20% from 2023 to a record low of $115 per kilowatt-hour, according to analysis by research provider BloombergNEF (BNEF).

The Price of 50 kWh Lithium Ion Batteries: A Comprehensive

Nov 5, 2024 · For example, when the price of lithium carbonate spiked in recent years, the cost of lithium-ion batteries also increased. However, as the supply of these raw materials stabilizes

LiFePO4 battery (Expert guide on lithium iron

Jun 4, 2021 · Lithium Iron Phosphate (LiFePO4) batteries continue to dominate the battery storage arena in 2025 thanks to their high energy density, compact

Estimating the tipping point for lithium iron phosphate batteries

Jan 1, 2025 · Among the most promising of these is lithium iron phosphate (LFP), a chemistry that offers a cost advantage over its NMC counterparts by substituting expensive nickel and cobalt

6 FAQs about [How much is the lithium iron phosphate battery pack ]

How much does a lithium iron phosphate battery cost?

Generally, the lithium iron phosphate battery price stands between $600 to $800. The price bracket of a 24V LiFePO4 battery is not different from a 12V battery. However, an increase or decrease in capacity can differentiate the price. It also ranges between $600 to $900, in 200AH capacity.

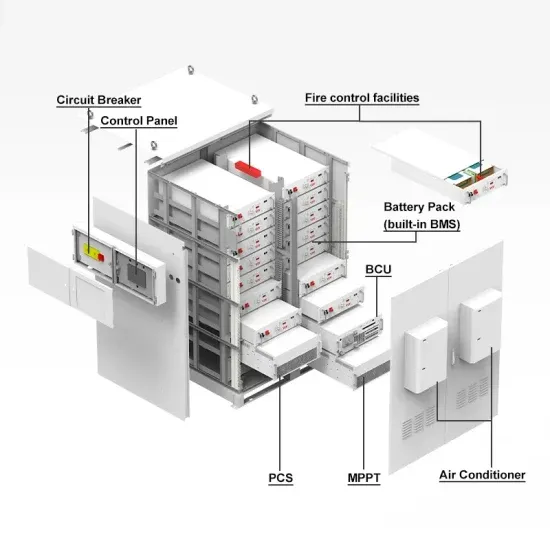

What is a lithium iron phosphate battery energy storage system?

The lithium iron phosphate battery energy storage system consists of a lithium iron phosphate battery pack, a battery management system (Battery Management System, BMS), a converter device (rectifier, inverter), a central monitoring system, and a transformer.

Is lithium iron phosphate a good battery?

Lithium iron phosphate, commonly known as LiFePO4, is becoming increasingly popular due to its safety, long lifespan, and durability. It can be a positive change for your electric devices as it does not need maintenance and frequent change. However, lithium iron phosphate battery price is 3 to 4 times higher than traditional batteries.

How much does a LiFePO4 battery cost?

Raw Material LiFePO4 battery combines lithium materials like lithium, cobalt, nickel, and graphite. The prices of materials like lithium cobalt oxide (LCO) are around $50 to $60 per kg, lithium iron phosphate (LFP) costs around $15 to $20 per kg, and lithium nickel manganese cobalt oxide (NMC) costs $25 to $35 per kg.

How will competition affect lithium iron phosphate battery prices?

Market Competition: The entry of new players and increased competition in the LiFePO4 battery market can put downward pressure on prices. Industry experts predict that lithium iron phosphate battery price per kWh could decrease by 30-50% over the next five to ten years.

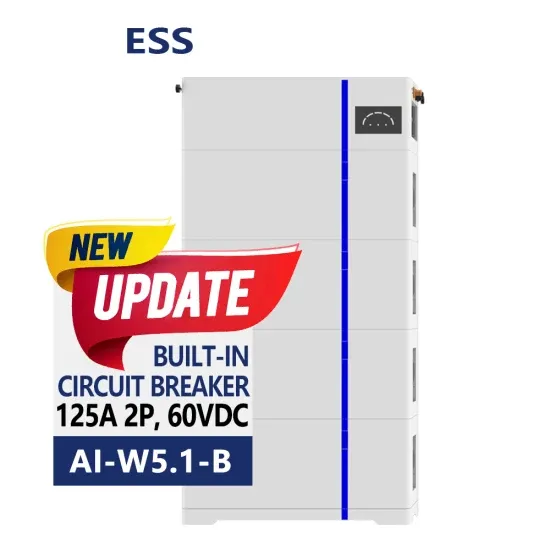

What is a LiFePO4 battery pack?

Suitable for a variety of applications, LiFePO4 battery packs offer excellent safety and impressive cycle life, while being lightweight, easy to use and affordable. Lithium iron phosphate battery pack is an advanced energy storage technology composed of cells, each cell is wrapped into a unit by multiple lithium-ion batteries.

Update Information

- Lithium iron phosphate battery pack 25 6v71 5ah

- Lithium iron phosphate battery pack press assembly

- Lithium iron phosphate battery pack product introduction

- Production of lithium iron phosphate battery pack

- 12V 3-channel 4-channel lithium iron phosphate battery pack

- How about lithium iron phosphate battery for photovoltaic energy storage cabinet

- 144v lithium iron phosphate battery pack

- Juba lithium iron phosphate battery pack

- N Djamena lithium iron phosphate battery pack

- Bulgaria s energy storage choice is lithium iron phosphate battery

- Replacement of lithium iron phosphate battery cabinet units at site

- Gb31241 How much can I buy a lithium battery pack

- Lithium iron phosphate battery container

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.