5s–7s Battery Pack Reference Design With Low-Side

Jan 3, 2024 · The design monitors each cell voltage, pack current, cell and metal-oxide semiconductor field-effect transistor (MOSFET) temperature with high accuracy and protects

What is the MOS in the lithium battery protection board?

Jul 17, 2021 · In view of the above two points, the Chinese Chuangfa reminds everyone that we must choose MOS with suitable withstand voltage and the lower the impedance, because the

Application of Power MOSFET in Battery Management

Jul 15, 2022 · Power MOSFETs are required to be connected in series between the inside of the lithium-ion battery pack and the output load. At the same time, the dedicated IC is used to

Understanding Li-Ion Battery Packs: A Complete Guide

Aug 8, 2024 · To start, let''s clarify what a Li-ion battery pack really is. Essentially, it''s a set of lithium-ion cells working together to provide a stable power source. Each cell is like a tiny

10s-16s Battery Pack Reference Design With Accurate

May 11, 2022 · Description This reference design is a low standby and ship-mode current consumption and high cell voltage accuracy 10s–16s Lithium-ion (Li-ion), LiFePO4 battery

TI BATTERY MANAGEMENT SYSTEMS SEMINAR

Sep 29, 2023 · Protecting a battery with FETs Lithium-Ion batteries need to be operated within specified limits Do not over-charge & Do not over-discharge MOSFETs commonly used for

MOS-013_App_Note_MG081721 dd

Aug 17, 2021 · Power MOSFETs are required to be connected in series between the lithium-ion battery pack and the output load. At the same time, a dedicated IC is used to control the on

LiFePO4 Lithium Battery | EVE 280K V3/EVE MB31 (314AH

🔋EVE 280K V3/EVE MB31 (314AH)/JK BMS/battery pack from EU,EVE 628ah from CN Grade A manufacturing report, can be verified. 8000 cycle -12000 cycles Free busbars, washers, epoxy

16s Battery Pack Ref. Des. W/ Low-Side MOSFET Control

Oct 27, 2022 · Features This reference design is a low current consumption and high cell voltage accuracy 16s Lithium-ion (Li-ion), LiFePO4 battery pack. The design monitors each cell

MoS2-based anode materials for lithium-ion batteries:

Apr 1, 2024 · Due to their distinct physicochemical characteristics, ultrathin nanosheets composed of common layered transition metal sulfide materials (MoS 2) have demonstrated promise as

BMS MOSFETs Explained

Dec 25, 2019 · This is the recommended way of doing it even with manual controls. You don''t want to keep current flowing through the diode - the diode is only there to make sure that you

The principle of the fuse in the circuit for the lithium ion battery

Jan 5, 2020 · During the use of lithium-ion rechargeable batteries, overcharge, overdischarge, and overcurrent will affect battery life, performance, and safety. The fuse in the rechargeable

Prelithiated MoS 2 Anode for All-Solid-State Lithium Batteries

May 31, 2025 · By a combination of Li x MoS 2, Li 6 PS 5 Cl (LPSC), and Li–In alloy, an all-solid-state lithium battery with superior long-term cycling and rate capability has been achieved. The

MOS-013_App_Note_MG081721 dd

Aug 17, 2021 · Introduction Power MOSFETs are required to be connected in series between the lithium-ion battery pack and the output load. At the same time, a dedicated IC is used to

6 FAQs about [What is MOS for lithium battery pack]

Why are two MOSFETs used in series in lithium-ion secondary battery protection circuit?

Why are two MOSFETs used in series in the Lithium-ion secondary battery protection circuit? Two MOSFET are used to realize both the charge and discharge functions. To realize both the charge and discharge functions, two MOSFET are used as shown in Fig. 1.

Do lithium ion batteries need a BMS system?

Lithium-ion batteries, especially custom lithium ion battery packs, need a BMS (Battery Management System) to ensure the battery is reliable and safe. The battery management system is the brain of the lithium battery and reports the status and health of the battery. Let’s get a better understanding from this article. What is a BMS System?

Can Mos 2 materials be used as lithium-ion battery anode?

Therefore, MoS 2 materials as lithium-ion battery anode have great limitations in practical applications. In recent years, a lot of research work has shown that the nano and composite MoS 2 powder materials are the two most effective ways to solve the above problems of MoS 2 anode materials. 4.1. MoS 2 /C based anode materials

What is IDSS of 30 volt MOSFET?

Battery Protection Board Circuit Diagram Usually, IDSS of 30 V MOSFET is less than 1 μA in the datasheet. In a practical notebook battery application, the battery voltage is usually from 9 V to 13.2 V. It is unknown whether the leakage current IDSS of the discharge MOSFET is higher than 100 nA or not under the battery voltage of 13.2 V.

How does a charge MOSFET work?

The charge MOSFET is turned on by the pre-charging function of the IC attempting to charge the battery. As a result, the IC starts to operate, and the static power loss of the battery will be increased. In critical cases, the battery will run out of power. Figure 28. Battery Protection Board Circuit Diagram

What is the battery capacity of a MOSFET?

Power MOSFET Placed at the Low-End with Electronic Fuse Ion battery capacity from the early 600 mAh, 1000 mAh, to now has reached 6000 mAh, 10000 mAh. In order to achieve faster-charging speed and shorter charging time, the fast charging technology of increasing current and charging with large current is usually adopted.

Update Information

- What do the lithium battery pack labels mean

- What is the resistance of a lithium battery pack

- What is the minimum voltage of the 6-series lithium battery pack in China and Europe

- What is the charging voltage of a 24V lithium battery pack

- What equipment will be used for lithium battery pack

- Caracas 12v lithium battery pack

- East Asia assembles EK lithium battery pack

- What is cp in lithium battery energy storage power station

- Replace lithium battery pack

- Does the battery pack contain lithium batteries

- 8 7 4v lithium battery pack

- H lithium battery pack

- Residual value of lithium battery pack

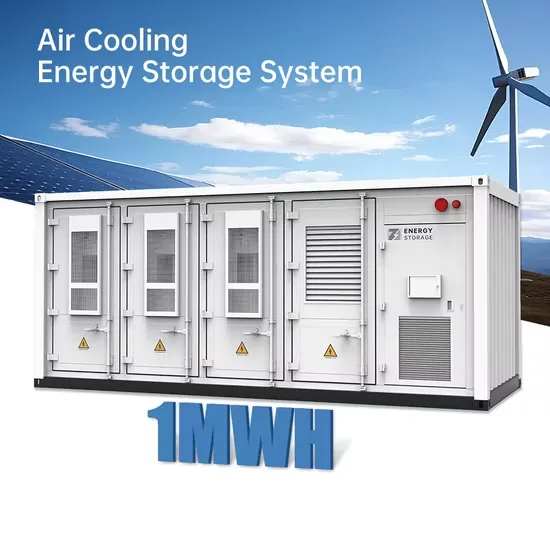

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.