Design and Performance Analysis of Active and Passive

Nov 5, 2023 · Design and Performance Analysis of Active and Passive Cell Balancing for Lithium-Ion Batteries Rakshak Udupa T S1, Shashank K Holla2* and Kariyappa B S3. 1Dept of

A novel active cell balancing topology for serially connected

Aug 10, 2024 · In a Battery Management System (BMS), cell balancing plays an essential role in mitigating inconsistencies of state of charge (SoCs) in lithium-ion (Li-ion) cells in a battery

A critical review of battery cell balancing techniques, optimal

Jun 1, 2024 · Considering the significant contribution of cell balancing in battery management system (BMS), this study provides a detailed overview of cell balancing methods and

(PDF) Formal approaches to design of active cell

Nov 7, 2016 · In this context, active cell balancing is a promising approach of the BMS to provide equal charge levels across the cells in the battery pack in an

Active cell balancing vs. Passive cell balancing in BMS

May 25, 2024 · Active and passive cell balancing are two essential techniques used in battery management systems (BMS) to maintain optimal performance and longevity of battery packs.

Battery Cell Balancing: What to Balance and How

Jun 26, 2007 · I. INTRODUCTION Different algorithms of cell balancing are often discussed when multiple serial cells are used in a battery pack for particular device. Means used to perform cell

An effective passive cell balancing technique for lithium-ion battery

Jul 1, 2025 · The increasing demand for clean transportation has propelled research and development in electric vehicles (EVs), with a crucial focus on enhancing battery technologies.

Active balancing vs. Passive balancing in Battery

Nov 18, 2024 · Active balancing and passive balancing are two methods used in battery management systems (BMS) to ensure that all cells within a battery

Novel active and passive balancing method-based battery management

Oct 20, 2021 · In this study, a novel battery management system (BMS) circuit topology based on passive and active balancing methods was created and implemented for battery-based

Active Cell Balancing of Lithium-ion Battery Pack Using Dual

Jan 1, 2021 · In recent years, the cell balancing topologies and algorithms for LIB packs are widely studied and reviewed [17,23]. The cell balancing topologies can be broadly classified

BMS Balancing: Active vs Passive Balancing Explained

Aug 6, 2025 · Battery cell balancing is a key function of Battery Management Systems (BMS) in multi-cell lithium battery packs. It ensures that all cells remain at similar voltage levels,

Active Balancing vs Passive Balancing Differences

Aug 6, 2025 · Battery cell balancing is a key function of Battery Management Systems (BMS) in multi-cell lithium battery packs. It ensures that all cells remain at similar voltage levels,

Programmable logic controlled lithium-ion battery

Jun 1, 2024 · In this study, a Programmable Logic Controller (PLC) - based BMS proposal for lithium-ion batteries has been presented, aiming to address the challenges in existing BMSs.

Passive Balancing vs Active Balancing in Lithium Batteries

Jun 19, 2025 · Active balancing, also known as active cell balancing, redistributes energy between cells in a lithium battery pack to achieve uniform voltage levels. Unlike passive methods, which

The Difference Between Active Balancing and Passive Balancing

Jun 27, 2025 · Passive balancing is more suitable for lithium battery packs with small capacity and low number of strings, while active balancing is more suitable for power lithium battery packs

Active Balancing: How It Works

Jul 17, 2024 · Passive balancing reduces cell SOC by placing a resistive load across individual cells (most commonly using BJT or MOSFET transistors). But active balancing takes a switch

A Better Life with Batteries – Achieving Energy Balance

6 days ago · The BMS not only controls charging and discharging voltage, current, and temperature to ensure battery safety, but also optimizes efficiency through cell balancing.

Passive Balancing vs Active Balancing in Lithium Batteries

Jun 19, 2025 · Active balance BMS systems excel in energy storage applications where efficiency directly impacts the overall life of the battery pack. Passive balance BMS systems, while

Active vs. Passive Balancing: A Guide to LiFePO4

Apr 25, 2023 · Balancing the cells is crucial when it comes to maintaining the performance and longevity of LiFePO4 battery packs. But did you know there

Update Information

- Lithium battery BMS active balancing

- San Diego Lithium Titanate Battery Pack BMS

- Alofi replaces lithium battery pack

- Which kind of Masai lithium battery pack is better

- Gaborone lithium battery pack

- How much is the Castries lithium battery pack

- 12 volt power supply with lithium battery pack

- Huawei lithium battery pack module automation

- 24v lithium battery pack 8 strings

- Lithium battery pack safety design

- Iran cylindrical lithium battery pack

- Cylindrical lithium battery pack has good quality

- Zero cycle battery secondary lithium battery pack

Solar Storage Container Market Growth

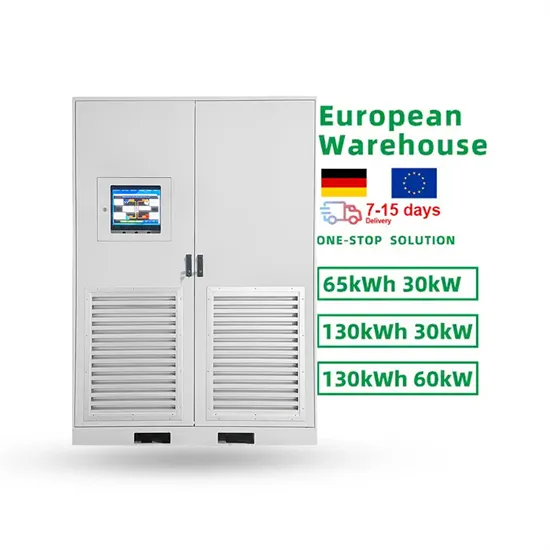

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.